Personalized Abs: A New Way to Get Fit

By:Admin

The latest addition to Customized Abs' product offerings is a result of the company's commitment to continuous innovation and customer satisfaction. By leveraging cutting-edge technology and industry expertise, Customized Abs has developed a range of abs products that cater to the diverse needs and preferences of its customers. Whether it's strength training, core workouts, or targeted abdominal exercises, Customized Abs has designed products to help individuals achieve their fitness goals efficiently.

One of the key highlights of Customized Abs' new line of abs products is its customization options. Customers can choose from a variety of features, including adjustable resistance levels, ergonomic design, and advanced tracking capabilities, to create a personalized workout experience that aligns with their fitness objectives. This level of customization sets Customized Abs apart from its competitors and reinforces the brand's dedication to empowering individuals to achieve peak performance.

In addition to its focus on product innovation, Customized Abs is committed to delivering exceptional customer service. The company's team of fitness experts and support staff are readily available to assist customers with product selection, usage guidance, and any other inquiries they may have. By prioritizing customer satisfaction, Customized Abs has built a loyal and satisfied customer base that continues to grow.

"We are thrilled to introduce our latest line of innovative abs products to the market," said [Spokesperson]. "At Customized Abs, we understand that fitness is not a one-size-fits-all journey. That's why we've developed a range of customizable products to cater to the unique needs and preferences of our customers. Whether you're a seasoned athlete or new to fitness, our abs products are designed to help you achieve the results you desire."

Customized Abs' commitment to excellence extends beyond its product offerings. The company actively seeks opportunities to give back to the community and promote health and wellness initiatives. Through partnerships with fitness influencers, charitable organizations, and community events, Customized Abs aims to encourage individuals to embrace an active lifestyle and prioritize their well-being.

As Customized Abs continues to push the boundaries of innovation in the fitness industry, the brand is poised for continued growth and success. With a focus on personalized solutions, exceptional customer support, and a passion for promoting fitness and well-being, Customized Abs is solidifying its position as a trusted leader in the fitness equipment market.

For more information about Customized Abs and its range of innovative abs products, visit [website] or contact the company directly. Whether you're looking to enhance your home gym or upgrade your fitness routine, Customized Abs has the solutions to help you reach your fitness goals.

Company News & Blog

Top Injection Molding Prototype Services for Product Development

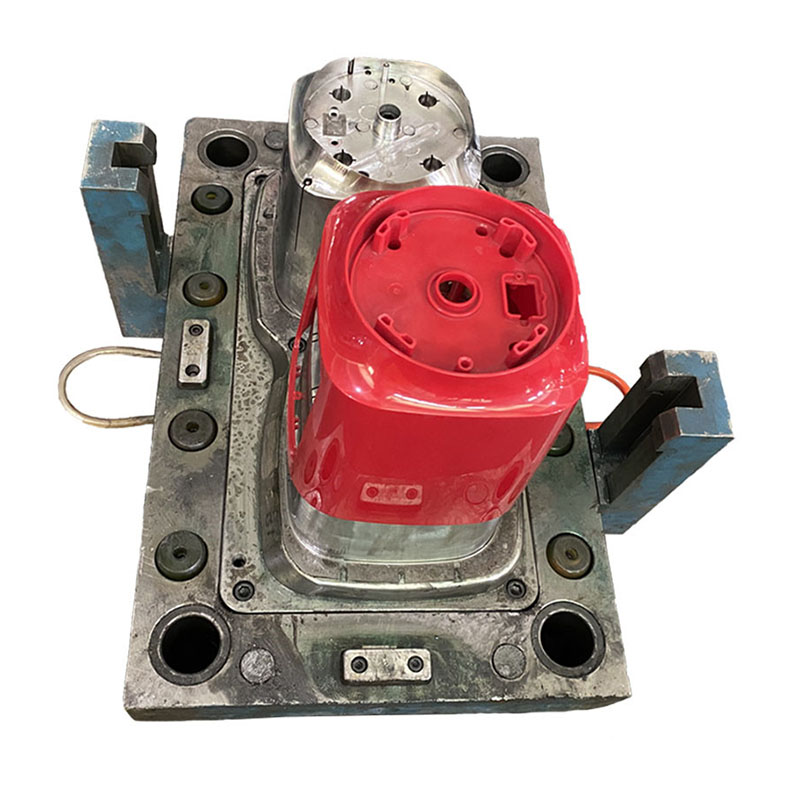

[Company Name] Introduces Cutting-Edge Injection Molding Prototype for Superior Product Development[City, State], [Date] - [Company Name], a leading provider of innovative manufacturing solutions, has announced the release of a state-of-the-art injection molding prototype. This new prototype is set to revolutionize the product development process, providing unparalleled precision and efficiency for a wide range of industries. Leveraging [Company Name]'s expertise in advanced manufacturing, the injection molding prototype is poised to make a significant impact on the market.The injection molding prototype is a testament to [Company Name]'s commitment to delivering cutting-edge solutions to its clients. With a focus on precision engineering and exceptional quality, this prototype sets a new standard for performance and reliability. By leveraging the latest technology and manufacturing techniques, [Company Name] is able to offer a prototype that exceeds industry standards and provides unmatched value for its customers."Innovation is at the core of [Company Name]'s philosophy, and the introduction of our injection molding prototype is a testament to that," said [Spokesperson], [Title] at [Company Name]. "We are constantly seeking out new ways to improve and enhance the product development process, and this prototype is a prime example of our dedication to pushing the boundaries of what is possible in manufacturing."With its advanced features and capabilities, the injection molding prototype is designed to meet the needs of the most demanding product development projects. Its precise and efficient molding process allows for the creation of complex and intricate parts with exceptional accuracy. This level of precision is vital for industries such as automotive, aerospace, medical devices, and consumer electronics, where high-quality components are essential for success.In addition to its superior performance, the injection molding prototype is also notable for its versatility. It can accommodate a wide range of materials, including plastics, metals, and composites, making it an ideal choice for a variety of applications. This flexibility gives [Company Name]'s clients the freedom to explore new possibilities and push the boundaries of what is achievable in product development.The introduction of the injection molding prototype is just the latest example of [Company Name]'s dedication to innovation and excellence. With a long history of providing industry-leading manufacturing solutions, [Company Name] has established itself as a trusted partner for companies around the world. Its commitment to quality, reliability, and customer satisfaction has earned the company a reputation for excellence in the manufacturing industry.As [Company Name] continues to push the boundaries of what is possible in manufacturing, it looks set to remain at the forefront of the industry for years to come. Its dedication to innovation and its ability to deliver cutting-edge solutions that exceed customer expectations will ensure that [Company Name] remains a leader in the field of advanced manufacturing.About [Company Name]:[Company Name] is a leading provider of innovative manufacturing solutions, with a focus on precision engineering and exceptional quality. With a long history of delivering industry-leading products and services, [Company Name] has earned a reputation for excellence in the manufacturing industry. Its commitment to innovation and customer satisfaction has made it a trusted partner for companies around the world. For more information, visit [company website].

Mastering the Technique of Injection Blow Mold for Superior Manufacturing Results

Title: Next Generation Injection Blow Mold Technology Revolutionizes Manufacturing ProcessesIntroduction: The injection blow mold technology, pioneered by a leading manufacturer, revolutionizes the manufacturing industry by streamlining production processes and increasing efficiency. This groundbreaking technology combines precision injection molding and blow molding techniques, raising the bar for innovation and quality in the industry. This article will delve into the various capabilities of this technology and how its integration into manufacturing processes offers numerous benefits for industries.Leveraging Advanced Technology to Enhance Production Processes:Brand's Injection Blow Mold technology represents a breakthrough in manufacturing as it seamlessly combines the injection molding and blow molding processes into a single, efficient operation. This integration eliminates the need for additional steps in the production cycle, reducing costs and optimizing production time. By using this advanced technology, manufacturers can enjoy significant gains in productivity, making it a game-changer for the industry.Accurate and Efficient Manufacturing:The Injection Blow Mold technology enables precise control over the product dimensions, resulting in consistent quality output. The process begins with injection molding, where the molten plastic is injected into a preform mold. It is then transferred to the blow molding station, where compressed air is introduced, expanding the plastic into the desired shape. This seamless transfer ensures minimal human intervention, reducing potential errors and ensuring accuracy in the manufacturing process.Advantages over Traditional Manufacturing Techniques:Compared to traditional manufacturing techniques, Injection Blow Mold technology offers several advantages. The elimination of separate injection molding and blow molding allows for decreased material waste, enhanced strength and integrity of the product, and improved overall production efficiency.Furthermore, this technology significantly reduces the cost of tooling and molds. The streamlined process not only results in reduced maintenance and setup time but also increases the reproducibility of molds, ensuring consistent quality throughout the production cycle.Diverse Applications and Industries:Injection Blow Mold technology finds application across a wide range of industries, such as automotive, packaging, aerospace, and medical. Its versatility in creating complex shapes and sizes makes it particularly useful in the production of bottles, containers, medical devices, and automotive components. By removing limitations imposed by traditional manufacturing techniques, this technology unlocks immense potential for innovation in various sectors.Enhanced Sustainability and Environmental Benefits:One of the key advantages of Injection Blow Mold technology is its environmentally friendly nature. The integration of the injection and blow molding processes results in reduced material waste, making it highly efficient and sustainable. Additionally, the ability to create lightweight products with superior strength reduces the overall energy consumption required during transportation and usage, contributing to a greener manufacturing process.The Company's Commitment to Innovation and Customer Success:As a leading manufacturer, the company behind this Injection Blow Mold technology prioritizes innovation and customer success. With a dedicated team of experts and state-of-the-art machinery, the company continuously strives to optimize manufacturing processes, deliver exceptional quality products, and offer unparalleled customer support. The steadfast commitment to innovation ensures their customers benefit from the most cutting-edge technologies in the industry.Conclusion:The integration of Injection Blow Mold technology into manufacturing processes ushers in a new era of efficiency, accuracy, and sustainability in the industry. Its ability to combine injection molding and blow molding techniques offers unparalleled advantages, including enhanced production efficiency, reduced material waste, improved product quality, and lowered manufacturing costs. With its diverse applications and suitability for various industries, this technology is set to shape the future of manufacturing, maximizing productivity and driving sustainable development.

Durable and Stylish Plastic Injection Molding Furniture for Your Home

Plastic Injection Molding Furniture is revolutionizing the furniture industry with its innovative approach to design and production. By utilizing plastic injection molding technology, this company is able to create stylish and durable furniture pieces that are both functional and aesthetically pleasing.With a focus on sustainability and environmental responsibility, Plastic Injection Molding Furniture has set itself apart from traditional furniture manufacturers. By using recycled materials and employing energy-efficient production methods, the company is committed to reducing its carbon footprint and minimizing waste.The company's commitment to quality and innovation is evident in its extensive product line, which includes chairs, tables, and storage units. Each piece is carefully designed to optimize both form and function, making them ideal for a wide range of commercial and residential spaces.One of the most impressive aspects of Plastic Injection Molding Furniture is its ability to customize products to meet the specific needs of its customers. Whether it's a unique color, shape, or size, the company has the capability to accommodate a variety of design preferences. This level of customization sets Plastic Injection Molding Furniture apart from its competitors and allows customers to create truly personalized furniture solutions.In addition to its commitment to quality and sustainability, Plastic Injection Molding Furniture also prides itself on its efficient production process. By utilizing state-of-the-art equipment and advanced manufacturing techniques, the company is able to produce high-quality furniture at a competitive price point. This makes their products an attractive option for both businesses and consumers looking for cost-effective and environmentally friendly furniture solutions.With a strong emphasis on customer satisfaction and a dedication to continuous improvement, Plastic Injection Molding Furniture is poised to become a leader in the furniture industry. The company's focus on innovation and sustainability has already garnered attention from industry professionals and consumers alike, and its reputation for quality and reliability continues to grow.In the coming months, Plastic Injection Molding Furniture plans to expand its product line and explore new opportunities for growth. With a team of experienced professionals and a solid foundation of values, the company is well-positioned to capitalize on the increasing demand for sustainable and customizable furniture solutions.Plastic Injection Molding Furniture's commitment to excellence and its unique approach to furniture manufacturing have set it apart as a pioneer in the industry. As more consumers and businesses prioritize sustainability and quality, the company's forward-thinking approach positions it for continued success in the years to come. With a focus on innovation, customization, and sustainability, Plastic Injection Molding Furniture is redefining the future of furniture design and production.

China's Plastic Molding and Injection Plastic Moulding Industry Reveals Promising Trends

China Mold Plastic Part Molding and Injection Plastic MouldIn recent years, China has experienced significant growth in the manufacturing industry, particularly in the plastic molding sector. Among the companies driving this surge is a prominent player in the market, which specializes in providing high-quality plastic part molding and injection plastic mould services. With state-of-the-art facilities and a highly skilled workforce, this company has established itself as a key player in the industry. Its commitment to excellence and customer satisfaction has allowed it to form partnerships with clients both domestically and internationally. The company's core offering is plastic part molding, which involves the process of creating plastic components for various industries. From automotive to electronics, household appliances to medical devices, their expertise spans across diverse sectors. With their cutting-edge technology and advanced machinery, they are capable of producing complex and intricate designs with precise specifications. The injection plastic mold services offered by the company are equally impressive. Injection molding is a popular manufacturing process that is widely used for producing plastic parts in large volumes. Through this process, molten plastic is injected into a mold cavity under high pressure, resulting in the formation of the desired shape. This company excels in providing high precision injection plastic molds that meet the highest industry standards. One of the key advantages of working with this company is their ability to offer customized solutions. They understand that each client has unique requirements, and they strive to deliver tailor-made products that match their specific needs. Whether it is a specific color, texture, or finishing, they work closely with their clients to ensure that the end product aligns with their vision. Quality control is of utmost importance to this company. They have implemented stringent measures to ensure that all products undergo rigorous testing and inspection to meet international quality standards. Their dedicated quality control team carries out comprehensive checks at every stage of the manufacturing process, leaving no room for error. This commitment to quality has earned them a solid reputation in the industry and has helped forge long-standing partnerships with their clients. Another notable aspect of this company is their commitment to sustainability. They understand the importance of environmental responsibility in today's world and have implemented eco-friendly practices in their manufacturing processes. They utilize recyclable materials and have implemented efficient waste management systems to minimize their ecological footprint. By investing in sustainable practices, they contribute to a greener future. In conclusion, this China-based company is a leading player in the plastic molding industry, offering top-notch plastic part molding and injection plastic mold services. Their commitment to excellence, customization, quality control, and sustainability has allowed them to stay ahead in the market. As China continues to witness a surge in manufacturing, this company is well-positioned to further expand its reach and cater to the diverse needs of clients around the world.

Top Plastic Injection Mould Manufacturer Offers Quality Products at Competitive Prices

Plastics Injection Mould Manufacturer, a leading provider of high-quality injection moulds for the plastics industry, has recently announced their continued commitment to excellence and customer satisfaction. With over 20 years of experience in the industry, the company has earned a reputation for delivering innovative solutions and superior products to their clients worldwide.As a prominent player in the plastics injection moulding sector, Plastics Injection Mould Manufacturer prides itself on its state-of-the-art facilities, cutting-edge technology, and a team of highly skilled professionals. Their dedication to precision engineering and attention to detail have enabled them to consistently meet the evolving demands of their customers across various industries, including automotive, medical, consumer goods, and more.Through their unwavering commitment to quality and continuous improvement, Plastics Injection Mould Manufacturer has built strong relationships with their clients, who rely on them for their moulding needs. The company's comprehensive range of services includes product design assistance, prototyping, tooling, and production, ensuring that they can offer end-to-end solutions for their customers' diverse requirements."We are proud to be at the forefront of the plastics injection moulding industry, delivering cutting-edge solutions that meet the highest standards of quality and performance," said the spokesperson of Plastics Injection Mould Manufacturer. "Our team is dedicated to pushing the boundaries of innovation and exceeding the expectations of our clients. We are committed to maintaining our position as a trusted partner in the industry, providing unparalleled expertise and support every step of the way."In addition to their commitment to excellence, Plastics Injection Mould Manufacturer is also focused on sustainability and environmental responsibility. The company has adopted eco-friendly manufacturing practices and invests in energy-efficient technologies to minimize their environmental impact. They are continuously exploring new ways to reduce waste and improve their environmental footprint, aligning with their dedication to corporate social responsibility.Furthermore, Plastics Injection Mould Manufacturer remains at the forefront of industry trends and advancements, constantly investing in research and development to enhance their capabilities and stay ahead of the competition. By staying abreast of the latest technologies and best practices, the company ensures that they can deliver cutting-edge solutions that empower their clients to remain competitive in their respective markets.As they move forward, Plastics Injection Mould Manufacturer is poised to continue their legacy of excellence, innovation, and customer-centric approach. With a firm commitment to quality, sustainability, and continuous improvement, the company is well-positioned to meet the evolving needs of the plastics industry and exceed the expectations of their valued clients.About Plastics Injection Mould ManufacturerPlastics Injection Mould Manufacturer is a leading provider of high-quality injection moulds for the plastics industry. With over 20 years of experience, the company is dedicated to delivering innovative solutions and superior products to clients worldwide. Their comprehensive range of services includes product design assistance, prototyping, tooling, and production, making them a trusted partner for end-to-end solutions. Plastics Injection Mould Manufacturer is committed to excellence, sustainability, and continuous improvement, setting industry standards and exceeding customer expectations.

High-Quality Plastic Granules for Injection Moulding: Everything You Need to Know

Plastic Granules For Injection Moulding have become a crucial component in the manufacturing industry, as they are used to produce a wide range of plastic products. One company that has been at the forefront of providing high-quality plastic granules for injection moulding is {Remove brand name}. Established in the year {insert year}, the company has been a reliable supplier of plastic granules, catering to the needs of various industries.{Remove brand name} has gained a strong reputation for its commitment to delivering top-notch products and excellent customer service. The company has a state-of-the-art manufacturing facility equipped with the latest technology for producing plastic granules that meet the highest industry standards. With a dedicated team of experts and a stringent quality control process, {Remove brand name} ensures that its plastic granules are of the finest quality, making them suitable for a wide range of injection moulding applications.One of the key factors that set {Remove brand name} apart from its competitors is its emphasis on sustainability. The company understands the environmental impact of plastic production and is committed to producing eco-friendly plastic granules. {Remove brand name} has invested in research and development to create biodegradable and recyclable plastic granules, thereby contributing to a greener and more sustainable future.Furthermore, {Remove brand name} offers a diverse range of plastic granules to cater to the specific requirements of different industries. Whether it is for automotive parts, packaging materials, consumer goods, or industrial products, {Remove brand name} has a comprehensive portfolio of plastic granules that are designed to meet the diverse needs of its customers. The company also provides custom formulation services, allowing it to develop tailored solutions for unique injection moulding applications.In addition to its commitment to producing high-quality plastic granules, {Remove brand name} is also dedicated to providing exceptional customer service. The company has a team of knowledgeable and experienced professionals who work closely with customers to understand their exact requirements and provide them with the most suitable plastic granules for their specific applications. {Remove brand name} also offers technical support and guidance to ensure that its customers achieve the best results from using its plastic granules.As part of its efforts to stay ahead in the industry, {Remove brand name} continually invests in research and development to improve its product offerings and expand its capabilities. The company keeps abreast of the latest advancements in injection moulding technology and materials, enabling it to stay at the forefront of innovation and deliver cutting-edge solutions to its customers.Furthermore, {Remove brand name} places a strong emphasis on maintaining a robust supply chain and distribution network, ensuring that its plastic granules are readily available to customers across the globe. The company has established strategic partnerships with logistics and distribution companies to streamline its operations and deliver its products efficiently to customers worldwide.In conclusion, {Remove brand name} has firmly established itself as a leading supplier of plastic granules for injection moulding. With a focus on quality, sustainability, innovation, and customer service, the company has earned the trust and confidence of its customers in various industries. As the demand for high-quality plastic products continues to grow, {Remove brand name} is well-positioned to meet the evolving needs of the market and remain a key player in the injection moulding industry.

Creating a High-Quality Plastic Injection Dustpan Mould: Everything You Need to Know

Plastic Injection Dustpan Mould, a leading provider of innovative plastic injection molding solutions, is making waves in the industry with their cutting-edge technology and commitment to excellence. With a strong emphasis on quality and precision, the company has carved a niche for itself in the highly competitive market.Plastic injection molding is a manufacturing process that involves injecting molten plastic into a mold to create a wide range of products, including dustpans. Plastic Injection Dustpan Mould has mastered this process, utilizing state-of-the-art equipment and techniques to deliver top-of-the-line dustpan molds to their clients.The company prides itself on its ability to cater to the diverse needs of its clients. From design to production, Plastic Injection Dustpan Mould offers a comprehensive range of services that are tailored to meet the specific requirements of each customer. Whether it's a custom mold for a unique dustpan design or a high-volume production run, the company has the capabilities to deliver results that exceed expectations.One of Plastic Injection Dustpan Mould's key strengths is its team of highly skilled professionals. With years of industry experience and a deep understanding of the intricacies of plastic injection molding, the company's personnel are able to provide valuable insights and recommendations to clients, ensuring the successful execution of each project. Their dedication to continuous improvement and innovation has enabled them to stay ahead of the curve and remain at the forefront of the industry.In addition to their technical expertise, Plastic Injection Dustpan Mould is also committed to environmental sustainability. The company understands the importance of reducing waste and minimizing their environmental footprint. As such, they have implemented various initiatives to promote eco-friendly practices throughout their operations, including the use of recyclable materials and energy-efficient production methods.Furthermore, Plastic Injection Dustpan Mould operates with a strong emphasis on quality control. Every mold undergoes rigorous testing and inspection to ensure that it meets the highest standards of durability, precision, and functionality. This unwavering commitment to quality has earned the company a solid reputation for reliability and consistency.With a proven track record of success and a strong focus on customer satisfaction, Plastic Injection Dustpan Mould has established itself as a trusted partner for businesses seeking top-notch plastic injection molding solutions. As the demand for high-quality dustpan molds continues to rise, the company is well-positioned to meet the evolving needs of the market and drive innovation in the industry.Looking ahead, Plastic Injection Dustpan Mould remains dedicated to pushing the boundaries of plastic injection molding technology. By investing in research and development, as well as forging strategic partnerships, the company is poised to expand its capabilities and further solidify its position as a leader in the industry.In conclusion, Plastic Injection Dustpan Mould has proven itself to be a formidable force in the plastic injection molding sector. With its focus on superior quality, technological prowess, and customer-centric approach, the company is well-equipped to thrive in a rapidly evolving market. As it continues to grow and evolve, Plastic Injection Dustpan Mould is set to make a lasting impact on the industry for years to come.

High-Quality Injection Plastic Mould for Chairs - Everything You Need to Know

Injection Plastic Mould For ChairThe injection plastic mould for chair has become an essential tool for companies in the furniture industry. This technology allows for the mass production of high-quality chairs at an efficient and cost-effective manner. With the increasing demand for durable and comfortable chairs, the use of injection plastic moulds has revolutionized the way chairs are made and has become a game-changer for the industry.[Company] has been a pioneer in the development and production of injection plastic moulds for chairs. With over [number] years of experience, they have established themselves as a leading provider of moulds and have played a significant role in shaping the future of the furniture industry. Their commitment to innovation and quality has earned them a solid reputation in the market, and they continue to push the boundaries of what is possible in chair production.Injection plastic moulds offer numerous advantages over traditional methods of chair production. They allow for the creation of complex and intricate designs that would be difficult or impossible to achieve using other methods. This opens up a world of possibilities for designers and manufacturers, who are now able to create chairs that are both aesthetically pleasing and functional. Additionally, the use of injection moulds results in chairs that are more consistent in quality and durability, ensuring that customers receive a product that meets their expectations.The process of creating a plastic mould for a chair begins with the design phase. This is where [Company] excels, as their team of experienced engineers and designers work closely with clients to bring their vision to life. Using advanced software and cutting-edge technology, they are able to develop highly detailed and precise mould designs that are tailored to the specific needs of the customer. This attention to detail is what sets [Company] apart and has allowed them to become a preferred partner for many furniture manufacturers.Once the design is finalized, the mould is created using state-of-the-art machinery and equipment. This is a precise and delicate process that requires expert craftsmanship and precision. [Company] has invested heavily in their manufacturing capabilities, ensuring that they have the tools and resources needed to produce high-quality moulds that meet the strictest standards of quality and performance. As a result, they are able to deliver moulds that are reliable, durable, and capable of withstanding the rigors of mass production.The final step in the process is the injection of plastic into the mould. This is where the magic happens, as the mould is filled with molten plastic and allowed to cool and harden. The result is a chair component that is strong, lightweight, and ready for assembly. The use of injection moulds ensures that each chair component is consistent in quality and dimensions, leading to a finished product that is reliable and visually appealing.Injection plastic moulds have had a profound impact on the furniture industry, and [Company] has been at the forefront of this transformation. Their dedication to innovation and quality has made them a trusted partner for many furniture manufacturers, and their moulds have helped to revolutionize the way chairs are made. As the demand for durable and stylish chairs continues to grow, the use of injection plastic moulds will undoubtedly play a crucial role in meeting this demand and shaping the future of the industry. With their expertise and commitment to excellence, [Company] is poised to remain a leader in the development and production of injection plastic moulds for chairs, driving innovation and helping to bring new and exciting designs to the market.

Ultimate Guide to Precision Plastic Injection Molds: Everything You Need to Know

[Company Name], a Leader in Precision Plastic Injection Molds, Revolutionizes the Manufacturing Industry[date]In today's competitive manufacturing industry, it is imperative for companies to stay at the forefront of technological advancements and provide high-quality products efficiently. Without a doubt, Precision Plastic Injection Mold (need remove brand name) has proven to be an influential player in this domain, setting industry standards and driving innovation. With a rich history of providing exceptional plastic injection molds, (Company Name) continues to revolutionize the manufacturing industry.Established in (year), (Company Name) has grown from a small operation to become a renowned leader in precision plastic injection molds. With expertise in designing and producing high-performance molds, the company has successfully met the ever-increasing demands of its clients in multiple sectors, including automotive, consumer electronics, medical devices, and industrial applications.What sets (Company Name) apart is its commitment to continuous improvement and innovation, ensuring that it remains ahead of the curve. The company's cutting-edge facilities are equipped with state-of-the-art manufacturing technologies, including Computer-Aided Design (CAD) software, Computer Numerical Control (CNC) machining centers, and advanced measurement equipment. This investment in modern technology helps (Company Name) to efficiently produce molds with intricate designs, high precision, and optimal performance.Furthermore, (Company Name)'s team of experienced engineers and designers collaborates closely with clients to understand their specific requirements and translate them into customized mold solutions. By employing a customer-centric approach, the company ensures that its molds meet the highest standards and are tailored to the unique needs of each application. With their expertise and creativity, (Company Name) consistently delivers molds that optimize production efficiency, reduce costs, and enhance product quality.Quality is of paramount importance at (Company Name). The company follows strict quality control measures at every stage of the manufacturing process, adhering to international standards and certifications. Molds manufactured by (Company Name) undergo rigorous testing to guarantee their reliability and durability. This commitment to quality has earned the company a stellar reputation as a trusted partner among its global clientele.Sustainability is another key focus for (Company Name). Recognizing the growing concern for environmental conservation, the company adopts eco-friendly practices throughout its operations. By utilizing recyclable materials and optimizing energy consumption, (Company Name) minimizes its environmental impact without compromising on the quality and performance of its molds. This dedication to sustainable manufacturing contributes to a greener future for the industry and the world.In line with its commitment to innovation, (Company Name) also invests heavily in research and development. The company's dedicated R&D team continuously explores new materials, manufacturing techniques, and design concepts to pioneer groundbreaking solutions. By staying at the forefront of technology, (Company Name) consistently introduces advanced mold designs with enhanced features, optimized cycle times, and reduced production costs, giving its clients a competitive edge in the market.With an impressive track record and an unwavering commitment to excellence, (Company Name) is poised to lead the manufacturing industry into the future. As the demand for precision plastic injection molds continues to grow, the company is well-positioned to meet these challenges head-on, providing industry-leading solutions that drive productivity and efficiency.In conclusion, (Company Name) has solidified itself as a frontrunner in the precision plastic injection mold industry, delivering innovative solutions that redefine manufacturing processes. With cutting-edge technology, a customer-centric approach, and a focus on quality and sustainability, the company continues to push boundaries and set new standards. As the manufacturing industry evolves, (Company Name) remains at the forefront of progress, shaping the future of precision plastic injection molds.

High-Quality Plastic Injection Molds for Sale: Find the Best Deals Now

The demand for high-quality plastic injection molds has been on the rise, and as a response to this growing demand, {Company Name}, a leading manufacturer in the plastic injection molding industry, has announced that they have a wide range of injection molds for sale.{Company Name} has been in the plastic injection molding business for over 20 years, and their expertise and experience in producing high-precision molds have made them a trusted name in the industry. They are known for their commitment to quality and innovation, and their injection molds are used in a wide range of industries, including automotive, medical, consumer goods, and electronics.The company's state-of-the-art manufacturing facility is equipped with the latest technology and machinery, allowing them to produce molds with incredibly tight tolerances and complex geometries. Their team of highly skilled engineers and technicians work tirelessly to ensure that each mold meets the highest standards of quality and performance.{Company Name}'s injection molds are also known for their durability and longevity, thanks to the use of high-quality materials and advanced manufacturing processes. This means that their molds are capable of producing thousands, or even millions, of high-quality plastic parts with minimal maintenance and downtime, making them an excellent investment for businesses looking to streamline their production processes.In addition to their standard injection molds, {Company Name} also offers custom mold design and manufacturing services, allowing their customers to create molds that are tailored to their specific needs and requirements. Whether it's a unique part design, a specialized material, or a specific production volume, the company's team can work closely with their clients to develop a custom mold solution that meets their exact specifications.{Company Name} takes great pride in their commitment to sustainability, and their injection molds are designed with environmental responsibility in mind. Their manufacturing processes are optimized to minimize waste and energy consumption, and they are constantly exploring new ways to reduce their environmental impact. This means that businesses can not only benefit from high-quality molds but also contribute to a more sustainable and eco-friendly manufacturing process.With the announcement of their injection molds for sale, {Company Name} is hoping to cater to the growing demand for high-quality molds in the market. Their extensive catalog of molds covers a wide range of applications and industries, and their custom mold services provide businesses with the flexibility to create molds that suit their unique needs.As the plastic injection molding industry continues to evolve, {Company Name} remains at the forefront of innovation and excellence. Their commitment to quality, precision, and sustainability sets them apart from other manufacturers, and their injection molds are a testament to their dedication to providing the best solutions for their customers.For businesses looking to invest in high-quality plastic injection molds, {Company Name} is a trusted partner that offers reliability, performance, and value. With their extensive experience and expertise, they have the capability to meet the most demanding mold requirements and exceed their customers' expectations.In conclusion, {Company Name}'s announcement of their plastic injection molds for sale is a testament to their ongoing commitment to excellence and innovation. Their injection molds are a result of years of expertise and dedication to quality, and they are poised to meet the growing demand for high-quality molds in the market. Businesses looking for reliable and high-performance injection molds need look no further than {Company Name}, a trusted leader in the industry.