Affordable Injection Mold: A Cost-Effective Solution for Manufacturing

By:Admin

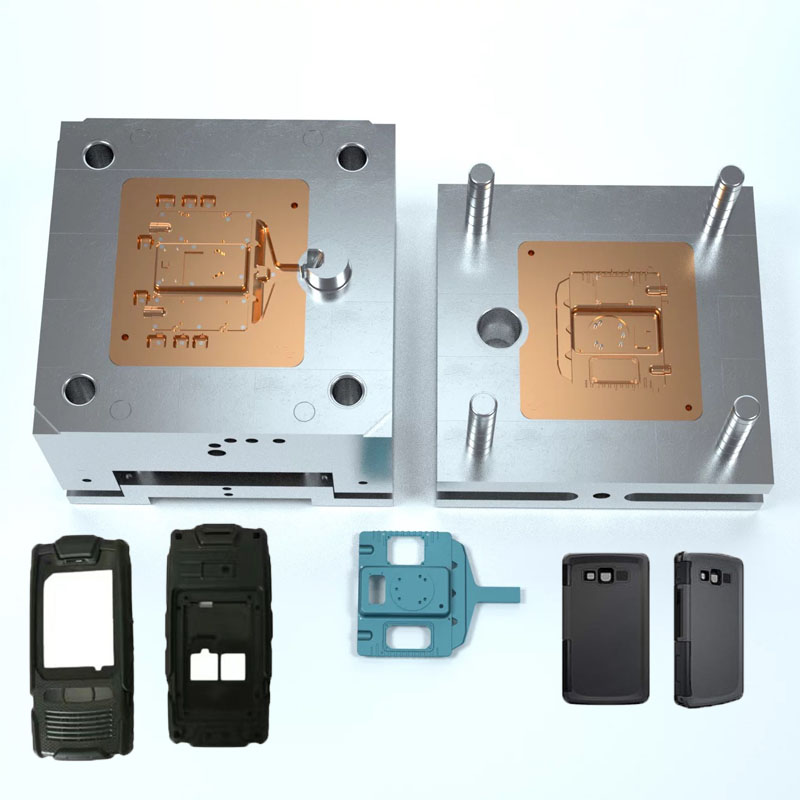

In today's competitive business environment, companies are constantly on the lookout for cost-effective and efficient manufacturing solutions. The injection mold industry is no exception, as it plays a crucial role in the production of various products, ranging from household items to automotive components. This is where the innovative and high-quality injection mold from a reputable company comes into play.

The company, based in [location], has recently introduced its new and affordable injection mold, which is set to revolutionize the manufacturing industry. With years of experience and a track record of delivering top-notch products, the company has become a trusted partner for businesses looking for reliable and innovative manufacturing solutions.

The injection mold offered by the company is not only affordable but also of high quality, making it an attractive option for businesses of all sizes. Whether it's a small-scale production or a large-scale manufacturing operation, this injection mold is designed to meet the diverse needs of businesses, while ensuring a seamless and efficient production process.

One of the key features of this injection mold is its durability and precision. The company has invested significantly in research and development to ensure that the mold is capable of withstanding the rigors of high-volume production, while maintaining precision and consistency in the finished products. This is a critical factor for businesses looking to maintain high standards of quality in their manufacturing processes.

Moreover, the injection mold is designed to be versatile, making it suitable for producing a wide range of products. Whether it's plastic components, metal parts, or composite materials, this mold has the capability to handle various types of materials, providing businesses with the flexibility they need to diversify their product offerings.

Another significant advantage of this injection mold is its cost-effectiveness. The company has taken a strategic approach to optimize the manufacturing process, which has resulted in a reduction in production costs. This, in turn, has allowed the company to offer the injection mold at a competitive price, making it an attractive option for businesses looking to minimize their production expenses.

The company has also prioritized customer satisfaction, offering comprehensive support and technical assistance to its clients. From initial consultations to post-sale support, the company's team of experts is dedicated to ensuring that their clients get the most out of the injection mold, helping them optimize their manufacturing processes and achieve their production goals.

With its affordable pricing, high quality, versatility, and customer-centric approach, the injection mold from this company is set to become a game changer for the manufacturing industry. It is expected to empower businesses to streamline their production processes, enhance product quality, and ultimately, gain a competitive edge in the market.

As the manufacturing industry continues to evolve, innovative solutions like the new injection mold from this company are instrumental in driving progress and efficiency. With its potential to revolutionize manufacturing processes, this injection mold is poised to make a significant impact on businesses across various industries, paving the way for a new era of cost-effective and superior production capabilities.

Company News & Blog

Quality Injection Molding Plastic Cup: A Complete Guide

ABC Company, a leading manufacturer of injection molded plastic products, has recently announced the launch of their latest product – a plastic cup designed for various commercial and industrial applications. The new plastic cup, which boasts of superior quality and durability, is expected to be a game-changer in the industry.With over 20 years of experience in the field of injection molding, ABC Company has established itself as a trusted name in the market. The company takes pride in its state-of-the-art manufacturing facility, equipped with the latest technology and machinery to ensure the production of high-quality plastic products. Their team of skilled engineers and technicians work tirelessly to develop innovative and sustainable solutions for their clients.The newly launched plastic cup is a testament to ABC Company’s commitment to delivering excellence in every product. Made from premium quality, food-grade plastic, the cup is designed to meet the rigorous demands of the commercial and industrial sectors. Its sleek and ergonomic design makes it suitable for a wide range of applications, including food and beverage service, hospitality, and healthcare industries.“We are thrilled to introduce our latest innovation in plastic products – the plastic cup. Our team has put in a tremendous amount of effort and dedication to develop a product that meets the highest standards of quality and durability. We are confident that this cup will set a new benchmark in the industry,” said the spokesperson of ABC Company.The plastic cup is manufactured using the latest injection molding technology, which ensures consistency in quality and precision in design. It is available in a range of sizes and colors to cater to the diverse needs of the market. The cup is also customizable, allowing businesses to add their branding and logo for a personalized touch.In addition to its superior quality, the plastic cup is also environmentally friendly, as it is reusable and recyclable. This aligns with ABC Company’s commitment to sustainability and reducing the environmental impact of their products. The company is dedicated to promoting eco-friendly solutions in the industry and is constantly working towards minimizing waste and energy consumption in their manufacturing processes.The launch of the plastic cup is expected to further strengthen ABC Company’s position as a market leader in injection molded plastic products. The company has already received positive feedback from their clients, who have praised the cup for its durability and versatility. With its competitive pricing and exceptional performance, the plastic cup is set to become a preferred choice for businesses looking for reliable and cost-effective plastic solutions.ABC Company is also offering customization and bulk ordering options for the plastic cup, making it convenient for businesses to procure the product according to their specific requirements. The company’s efficient logistics and distribution network ensure timely delivery of the product to their clients, regardless of their location.As ABC Company continues to innovate and expand its product portfolio, the launch of the plastic cup has undoubtedly made a significant impact in the industry. With its unwavering commitment to quality, sustainability, and customer satisfaction, ABC Company is poised to lead the way in the injection molding plastic products market.

Discover the Incredible Value of Smoothie Juicer Blenders and Food Blenders in China

Title: Chinese Smoothie Juicers and Blenders Reshape the MarketIntroduction:China's smoothie juicer blender and food blender market is witnessing a significant surge in demand as consumers increasingly embrace healthier lifestyles. These high-performance appliances are bridging the gap between convenience and wellness by offering versatile options for creating nutritious drinks and meals at home. Let's explore the current trends and key players in this booming industry.Rising Popularity:In recent years, there has been a remarkable shift in consumer preferences towards healthier food choices, leading to an upsurge in the demand for smoothies and blended recipes. This shift can be attributed to heightened awareness of the importance of a balanced diet and the desire to maintain a healthy lifestyle. Chinese smoothie juicer blender and food blender manufacturers have stepped up to cater to this growing demand, providing consumers with innovative options for creating delicious and nutrient-rich concoctions.Tech-Driven Features:One of the key reasons behind the success of Chinese smoothie juicer blender and food blender brands is their focus on advanced technology. These blenders feature powerful motors that crush through dense ingredients, ensuring a smooth consistency. Additionally, many models incorporate smart features such as preset programs, touch control panels, and even Bluetooth connectivity, making the blending experience more convenient and intuitive.Competitive Pricing:Chinese brands have gained a competitive edge in the global market due to their affordability. These smoothie juicer blender and food blender offerings combine quality with cost-effectiveness, making them accessible to a wider range of consumers. By avoiding excessive price tags, Chinese manufacturers have managed to capture both domestic and international markets, challenging established global brands.Efficiency and Durability:With a strong emphasis on quality and durability, Chinese smoothie juicer blender and food blender manufacturers have garnered trust and loyalty from customers. These appliances are designed to withstand intense usage, boasting robust materials and efficient engineering. Their long-lasting performance translates into a wise investment for consumers, offering both reliability and value for money.Market Leaders:As the market expands, several notable Chinese brands have emerged as key players, setting new standards in terms of functionality and design. These industry leaders offer a comprehensive range of smoothie juicer blenders and food blenders, catering to varying needs and preferences.One such prominent brand is X Company, known for its cutting-edge innovations in the blending industry. Their wide product range caters to beginners and professionals alike, with options designed specifically for smoothies, soups, or even baby food. X Company leverages advanced technology to deliver superior blending performance, making them a top choice among consumers.Another noteworthy brand is Y Company, renowned for its commitment to health and wellness. Y Company's blenders are equipped with unique features like personal blending cups and precise nutrient extraction modes, enabling users to tailor their blend according to specific dietary requirements. The brand's dedication to promoting healthy lifestyles has been well-received by health-conscious consumers.Conclusion:Chinese smoothie juicer blender and food blender brands have revolutionized the market, offering consumers an extensive range of affordable and feature-packed options. With a focus on technology, efficiency, and durability, these appliances have become an indispensable tool for individuals seeking to lead a healthier lifestyle. As the market continues to evolve, it is expected that Chinese brands will continue to innovate and cater to the ever-growing demand for high-quality and versatile blending solutions.

Benefits of Mould Injection Molding for Manufacturing

Mould Injection Molding Technology Revolutionizes Manufacturing IndustryIn recent years, manufacturing technology has been rapidly evolving to meet the growing demands of the global market. One of the most game-changing advancements in this field has been the development of Mould Injection Molding technology, a process that has revolutionized the way products are produced and has significantly impacted industries across the board.Mould Injection Molding is a manufacturing process that involves injecting a molten material, typically plastic or metal, into a mold. This process is used to create a wide range of products, including automotive parts, medical devices, consumer goods, and more. The technology allows for the production of complex and intricately designed parts with precision and efficiency, making it a go-to method for many manufacturers.One of the leading companies in the Mould Injection Molding industry is {}. With several years of experience and a proven track record of delivering high-quality products, {} has established itself as a trusted and reliable partner for manufacturers across various industries. The company's state-of-the-art facilities and cutting-edge technologies have enabled them to offer a wide range of Mould Injection Molding services, including design and engineering, prototyping, and mass production.{}'s commitment to innovation and continuous improvement has allowed them to stay ahead of the curve in the rapidly evolving manufacturing landscape. The company's team of skilled engineers and technicians work closely with clients to understand their specific needs and provide customized solutions that meet and exceed expectations. By employing advanced Mould Injection Molding techniques, {} is able to produce complex parts with high precision, tight tolerances, and superior surface finishes.One of the key advantages of Mould Injection Molding technology is its ability to produce large volumes of parts with minimal waste and cost. This makes it an ideal solution for mass production, allowing manufacturers to meet high demands without compromising on quality or efficiency. Furthermore, the flexibility of Mould Injection Molding allows for the production of parts in a wide range of shapes, sizes, and materials, making it a versatile and adaptable process for diverse applications.With growing concerns about environmental sustainability, manufacturers are under increasing pressure to adopt more eco-friendly production methods. Mould Injection Molding addresses this challenge by optimizing material usage and minimizing waste, leading to a more sustainable and cost-effective manufacturing process. By leveraging this technology, manufacturers can reduce their environmental footprint while enhancing their production capabilities.The impact of Mould Injection Molding technology goes beyond the manufacturing sector, extending to a wide range of industries and applications. From automotive and aerospace to medical and consumer goods, the versatility and efficiency of this technology have made it a game-changer for businesses seeking to stay competitive in today's fast-paced marketplace.As the demand for high-quality, precision-engineered parts continues to grow, the importance of Mould Injection Molding technology cannot be overstated. Its ability to deliver complex parts with unmatched precision and speed has positioned it as a cornerstone of modern manufacturing.In conclusion, Mould Injection Molding technology has transformed the manufacturing industry by offering a reliable, efficient, and cost-effective solution for producing high-quality parts. With the expertise and cutting-edge capabilities of companies like {}, manufacturers can leverage this technology to stay ahead of the competition and meet the evolving demands of the global market. As Mould Injection Molding continues to advance and evolve, it is poised to play an even more significant role in shaping the future of manufacturing.

Plastic Cup Injection Molding: Everything You Need to Know

Injection Molding Plastic Cup, a New Milestone Achievement for {Company}In today's fast-paced world, the development of new products is essential for companies to stay competitive in the market. One such innovative product that has recently been introduced by {Company} is the Injection Molding Plastic Cup. This new milestone achievement has set a benchmark in the industry, showcasing {Company}'s commitment to innovation and quality.{Company} is a leading manufacturer in the plastic industry, specializing in producing high-quality plastic products for various applications. With state-of-the-art facilities and a team of experienced professionals, {Company} has been at the forefront of technology and innovation. The company's commitment to sustainability and environmental responsibility has also been a driving force behind its success.The Injection Molding Plastic Cup is the latest addition to {Company}'s extensive product line. This innovative product has been designed to meet the growing demand for eco-friendly and durable plastic cups in the market. The cup is manufactured using advanced injection molding techniques, ensuring consistent quality and precision.One of the key features of the Injection Molding Plastic Cup is its durability. The cup is designed to withstand the rigors of daily use, making it ideal for both commercial and residential purposes. The high-quality plastic material used in the manufacturing process ensures that the cup is resistant to cracks, breakage, and deformation, making it a reliable choice for consumers.In addition to durability, the Injection Molding Plastic Cup also offers superior aesthetics. The cup is available in a range of attractive colors and finishes, catering to different consumer preferences. This attention to design and appearance reflects {Company}'s commitment to delivering products that not only perform well but also look great.Furthermore, the Injection Molding Plastic Cup is also a sustainable choice. {Company}'s focus on eco-friendly manufacturing practices has led to the development of a product that is recyclable and environmentally responsible. By choosing the Injection Molding Plastic Cup, consumers can contribute to the reduction of plastic waste and support sustainable initiatives.{Company} has invested significant resources into the research and development of the Injection Molding Plastic Cup, ensuring that it meets the highest standards of quality and performance. The company's dedication to continuous improvement and innovation is evident in the superior design and functionality of the product.Moreover, {Company} has also taken steps to ensure that the Injection Molding Plastic Cup complies with industry regulations and standards. Through rigorous testing and quality control measures, the company has demonstrated its commitment to delivering a product that meets the expectations of consumers and industry stakeholders.The introduction of the Injection Molding Plastic Cup is a significant milestone for {Company}, reaffirming its position as a leader in the plastic manufacturing industry. The company's ability to innovate and adapt to changing market demands sets it apart from its competitors, positioning it as a trusted partner for businesses and consumers alike.With the Injection Molding Plastic Cup, {Company} has once again demonstrated its ability to deliver products that combine quality, sustainability, and innovation. As the company continues to expand its product offerings, it is poised to make a lasting impact on the industry and set new standards for excellence.

Discover the Latest High Precision Plastic Injection Molding Parts

[Company Name] Empowers Industries with High Precision Plastic Injection Molding Parts[date][City, State] - [Company Name], a leading provider of high precision plastic injection molding parts, is revolutionizing the manufacturing sector with its cutting-edge technology and expertise. With a focus on delivering impeccable quality and unmatched precision, [Company Name] is poised to empower industries with its innovative solutions.Plastic injection molding is a widely used manufacturing process that has transformed various industries by creating complex and intricate parts with high accuracy and efficiency. The process involves injecting molten plastic into a mold cavity, which then solidifies to form the desired component. [Company Name] has mastered this technique, guaranteeing precise and consistent results every time.The secret to [Company Name]'s success lies in its state-of-the-art manufacturing facility, equipped with the latest machinery and technology. The company utilizes advanced computer-aided design (CAD) software and computer numerical control (CNC) machines for producing molds with exceptional precision. This allows [Company Name] to create intricate parts that meet even the most demanding specifications.Furthermore, [Company Name] takes great pride in its team of highly skilled technicians and engineers. They possess a deep understanding of plastic injection molding and are committed to delivering superior quality products. With their expertise, [Company Name] consistently produces high-grade plastic parts that meet or exceed industry standards.As a leader in the plastic injection molding industry, [Company Name] caters to a wide range of sectors, including automotive, electronics, medical, and consumer goods. The company's extensive product portfolio includes components such as housings, connectors, gears, and various other complex parts. These parts are used in critical applications where precision and durability are paramount.In addition to its dedication to precision and quality, [Company Name] also places a strong emphasis on sustainability. The company recognizes the importance of minimizing its environmental impact and actively seeks ways to reduce waste and energy consumption. By adopting eco-friendly practices, such as recycling and using bio-based materials, [Company Name] aims to contribute to a greener and more sustainable future.To ensure the highest level of customer satisfaction, [Company Name] provides comprehensive support throughout the entire manufacturing process. From initial design and prototyping to final production, the company works closely with its clients, offering expert advice and guidance. This collaborative approach allows [Company Name] to tailor its solutions according to the specific needs and requirements of each customer.As testament to its dedication to excellence, [Company Name] has earned numerous certifications and accolades, including ISO 9001 and ISO 14001. These certifications validate the company's commitment to quality management and environmental stewardship, further instilling confidence in its customers.With its relentless pursuit of perfection, [Company Name] is poised to make a significant impact on the manufacturing sector. By offering high precision plastic injection molding parts and embracing sustainable practices, the company is driving innovation and transforming industries. Whether it's enhancing automotive performance, improving medical devices, or enabling cutting-edge electronics, [company name] is revolutionizing the way industries operate.In conclusion, [Company Name] is revolutionizing the manufacturing sector with its high precision plastic injection molding parts. Through advanced technology, a skilled workforce, and a commitment to sustainability, the company is empowering industries and driving innovation. With its unwavering dedication to excellence, [Company Name] is set to continue its growth and make a lasting impact on the global manufacturing landscape.

Plastic Injection Mould Molding Services for Custom Projects

Custom Plastic Injection Mould Molding is a company dedicated to providing high-quality plastic injection molding services for a wide range of industries. With their state-of-the-art facilities and experienced team of engineers and technicians, they are able to offer custom solutions for a variety of plastic molding needs.The company specializes in the design and manufacture of custom plastic molds, using advanced CAD/CAM software and CNC machining to create precise and complex mold designs. They work closely with their clients to understand their specific requirements and ensure that the final product meets their exact specifications.In addition to custom mold design and manufacturing, Custom Plastic Injection Mould Molding also offers a full range of plastic injection molding services. Their modern injection molding machines are capable of producing parts in a wide range of sizes and complexities, using a variety of thermoplastic and thermoset materials.One of the key advantages of working with Custom Plastic Injection Mould Molding is their ability to offer rapid prototyping services. This allows their clients to quickly and cost-effectively test new product designs before full-scale production, reducing time to market and minimizing risks.The company has a strong commitment to quality, and they adhere to strict quality control procedures throughout the entire manufacturing process. This ensures that every part they produce meets the highest standards of durability and performance.Custom Plastic Injection Mould Molding serves a diverse range of industries, including automotive, aerospace, medical, consumer electronics, and more. They have the flexibility to handle both low and high volume production runs, making them an ideal partner for companies of all sizes.In addition to their technical capabilities, Custom Plastic Injection Mould Molding is also dedicated to sustainability and environmental responsibility. They strive to minimize waste and energy consumption in their manufacturing processes, and they are able to offer eco-friendly material options for clients who are looking to reduce their environmental impact.With a strong focus on innovation and customer satisfaction, the team at Custom Plastic Injection Mould Molding is constantly looking for new ways to improve their processes and expand their capabilities. They invest in ongoing training and development for their employees, ensuring that they are always able to offer the latest and most advanced plastic molding solutions.In summary, Custom Plastic Injection Mould Molding is a leading provider of custom plastic injection molding services, offering high-quality, cost-effective solutions for a wide range of industries. With their advanced technology, commitment to quality, and strong focus on customer satisfaction, they are well-positioned to continue as a trusted partner for companies looking for custom plastic molding solutions.

High-quality Stamping and Hardware Products from China

China Stamping and Hardware is a leading manufacturer of precision metal stamping and hardware components. With over 20 years of experience in the industry, the company has built a reputation for delivering high-quality products to customers worldwide. From automotive parts to electronic components, China Stamping and Hardware has the capabilities to produce a wide range of custom metal stampings.The company prides itself on its state-of-the-art manufacturing facilities, which are equipped with the latest technology and machinery. This allows China Stamping and Hardware to maintain strict quality control measures throughout the production process, ensuring that all products meet the highest standards. In addition, the company's team of experienced engineers and technicians are dedicated to providing innovative solutions to meet the unique needs of their customers.Recently, China Stamping and Hardware announced a major expansion to their manufacturing facilities in order to meet the growing demand for their products. The expansion will include the addition of new machinery and equipment, as well as the hiring of additional staff to support increased production. This investment underscores the company's commitment to delivering top-quality products to their customers while maintaining a competitive edge in the market.In addition to their expansion efforts, China Stamping and Hardware has also been exploring new opportunities for growth and innovation. The company has been investing in research and development to stay ahead of industry trends and develop new technologies for metal stamping and hardware production. By staying at the forefront of technological advancements, China Stamping and Hardware aims to continue providing cutting-edge solutions to their customers.Furthermore, the company has been proactive in implementing sustainable practices within their manufacturing processes. By adopting eco-friendly materials and investing in energy-efficient technology, China Stamping and Hardware is minimizing its environmental impact while also reducing costs. This commitment to sustainability aligns with the company's values of social responsibility and environmental stewardship.Moreover, China Stamping and Hardware has been recognized for its dedication to quality and excellence in the industry. The company holds various certifications and accreditations that demonstrate their adherence to international standards and regulatory requirements. This includes ISO 9001 certification, which is a testament to their commitment to delivering products of the highest quality.Overall, China Stamping and Hardware's expansion and dedication to innovation and quality demonstrate their ongoing commitment to providing exceptional products and services to their customers. With a strong focus on sustainability and continuous improvement, the company is well-positioned to meet the evolving needs of the marketplace and maintain its leadership in the industry.In conclusion, China Stamping and Hardware's expansion and dedication to innovation and quality demonstrate their ongoing commitment to providing exceptional products and services to their customers. With a strong focus on sustainability and continuous improvement, the company is well-positioned to meet the evolving needs of the marketplace and maintain its leadership in the industry.

A complete guide to injection molding techniques

Injection Mold Or Injection Molding is a widely used manufacturing process for creating a variety of products, from plastic components to metal parts. It involves injecting molten material into a mold, which is then cooled and solidified to form the desired shape. This process is used in a wide range of industries, including automotive, aerospace, electronics, and medical devices.One company that has excelled in the field of Injection Mold Or Injection Molding is {}. {} has been at the forefront of innovation and excellence in this industry for over twenty years. With a strong emphasis on quality, precision, and efficiency, {} has established itself as a leading provider of injection molding services.Injection Mold Or Injection Molding process at {} is a highly controlled and precise operation. The company utilizes state-of-the-art equipment and advanced technologies to ensure that every product meets the highest standards of quality and accuracy. With a team of experienced engineers and technicians, {} is able to provide custom solutions for a wide range of manufacturing needs.{} is capable of handling a wide variety of materials, including various types of plastics, metals, and composites. This allows the company to create custom solutions for a diverse set of industries and applications. Whether it's producing intricate plastic components for the automotive industry or creating precision metal parts for aerospace applications, {} has the expertise and capabilities to deliver high-quality products.In addition to its manufacturing capabilities, {} also offers design and engineering services to help clients bring their ideas to life. With a focus on innovation and collaboration, the company works closely with its clients to develop custom solutions that meet their specific requirements. Whether it's creating a new product from scratch or optimizing an existing design for manufacturability, {} has the expertise and resources to make it happen.One of the key advantages of Injection Mold Or Injection Molding is its ability to produce high volumes of parts with excellent consistency and repeatability. This makes it an ideal solution for mass production and large-scale manufacturing needs. Whether it's producing small, intricate components or large, complex parts, {} has the capacity and expertise to deliver reliable, high-quality products on a consistent basis.As a provider of injection molding services, {} is committed to sustainability and environmental responsibility. The company utilizes efficient manufacturing processes and sustainable materials to minimize its environmental impact. This commitment to sustainability not only benefits the environment, but also helps clients meet their own sustainability goals and requirements.With a strong track record of delivering high-quality products and a commitment to innovation and excellence, {} is well-positioned to continue its leadership in the field of Injection Mold Or Injection Molding. As the demand for custom manufacturing solutions continues to grow, {} is dedicated to providing the highest level of service and quality to its clients.In conclusion, Injection Mold Or Injection Molding is a critical manufacturing process used in a wide range of industries. {} has established itself as a leading provider of injection molding services, with a strong emphasis on quality, precision, and efficiency. With a focus on innovation and collaboration, {} is well-equipped to meet the diverse needs of its clients and deliver high-quality products on a consistent basis.

High-Quality Plastic Injection Molding for Custom Products

Custom Molding Plastic Injection Mold Strengthening its Position in the MarketCustom Molding Plastic Injection Mold has been making significant strides in the plastic injection molding industry, solidifying its position as a leading provider of high-quality custom plastic parts. With a commitment to innovation and customer satisfaction, the company has continued to expand its capabilities and offerings, positioning itself as a valuable partner for businesses across various industries.The company has built a strong reputation for delivering precise and reliable plastic injection molding solutions for a wide range of applications. With expertise in manufacturing custom plastic parts for industries such as automotive, medical, consumer goods, and electronics, Custom Molding Plastic Injection Mold has proven to be a trusted partner for businesses with diverse manufacturing needs.One of the key factors that have contributed to the company's success is its state-of-the-art manufacturing facilities and advanced injection molding technology. Custom Molding Plastic Injection Mold has heavily invested in cutting-edge equipment and machinery, allowing it to produce complex and intricate plastic parts with a high degree of accuracy and consistency. This commitment to technology and innovation has enabled the company to meet the evolving needs of its customers and maintain its competitive edge in the industry.In addition to its manufacturing capabilities, Custom Molding Plastic Injection Mold excels in providing comprehensive design and engineering support to its clients. The company's team of experienced engineers and designers work closely with customers to develop custom molds and parts that meet their specific requirements. From concept to production, Custom Molding Plastic Injection Mold offers a full-service approach that ensures the success of each project.Furthermore, the company places a strong emphasis on quality control and assurance throughout the manufacturing process. With rigorous testing and inspection protocols in place, Custom Molding Plastic Injection Mold ensures that each part meets the highest standards of quality and performance before it is delivered to the customer. This commitment to quality has earned the company a reputation for reliability and consistency in the industry.As part of its ongoing efforts to enhance its capabilities and expand its product offerings, Custom Molding Plastic Injection Mold recently announced the acquisition of new technology and equipment to further strengthen its position in the market. By investing in the latest advancements in plastic injection molding, the company aims to increase its production capacity, improve efficiency, and stay at the forefront of technological innovation in the industry."We are thrilled to bring in new technology and equipment that will elevate our manufacturing capabilities to new heights," said [company spokesperson]. "This investment reflects our dedication to providing our customers with the best possible solutions and staying ahead of the curve in the plastic injection molding industry."With the acquisition of new technology, Custom Molding Plastic Injection Mold is well-prepared to meet the growing demand for custom plastic parts and molds from its diverse customer base. The company is confident that the added capabilities will not only enhance its ability to deliver high-quality products but also open up opportunities for further expansion and development in the future.As Custom Molding Plastic Injection Mold continues to strengthen its position in the market, the company remains focused on providing exceptional service, unparalleled expertise, and innovative solutions to its customers. With a steadfast commitment to excellence and a forward-thinking approach, Custom Molding Plastic Injection Mold is poised for continued success and growth in the plastic injection molding industry.

High-Quality Plastic Injection Mould Canulas for Medical Applications

Plastic Injection Mould Cannula: The Future of Medical InstrumentationIn the ever-evolving field of medical instrumentation, innovation is key to improving patient care and outcomes. One such innovation that has been making waves in the medical industry is the Plastic Injection Mould Cannula, a cutting-edge tool that is set to revolutionize the way medical procedures are conducted. This state-of-the-art cannula, which is manufactured by [], has been hailed as a game-changer in the medical device industry, and for good reason.The Plastic Injection Mould Cannula is a versatile and highly efficient tool that is used in a wide range of medical procedures, including cosmetic surgeries, liposuction, and various other surgical and non-surgical medical procedures. It is designed to be lightweight, durable, and easy to use, making it an essential instrument for medical professionals. The cannula’s unique design allows for precise control and maneuverability, which is crucial in delicate medical procedures.One of the most impressive features of the Plastic Injection Mould Cannula is its use of cutting-edge materials and manufacturing processes. The cannula is created using advanced plastic injection molding technology, which ensures its durability and reliability. This process allows for the production of cannulas that are consistently high-quality, with superior performance and safety standards. Furthermore, the use of this technology enables the production of cannulas that are cost-effective and readily available, making them accessible to medical professionals worldwide.The Plastic Injection Mould Cannula is a clear example of how innovation in medical instrumentation can lead to better patient outcomes. Its advanced design and manufacturing processes make it a highly reliable tool that medical professionals can trust. By providing superior control and precision, the cannula allows for more precise and effective medical procedures. This not only benefits patients by reducing the risk of complications but also allows for faster recovery times and better overall results.In addition to its numerous advantages, the Plastic Injection Mould Cannula also reflects the commitment of [] to excellence in medical device manufacturing. This company is dedicated to producing high-quality medical instruments that meet the highest industry standards. By leveraging the latest technologies and materials, they are able to create products that not only meet the needs of medical professionals but also surpass their expectations. As a result, [] has become a trusted name in the medical device industry, known for their unwavering commitment to quality and innovation.The introduction of the Plastic Injection Mould Cannula is a testament to the ongoing advancements in medical instrumentation. As the medical industry continues to evolve, it is clear that innovative tools like this cannula will play a vital role in improving patient care and outcomes. With its state-of-the-art design and manufacturing, the Plastic Injection Mould Cannula is set to become a cornerstone of modern medical procedures. As [] continues to push the boundaries of medical device manufacturing, it is certain that we can look forward to even more groundbreaking innovations in the future. The Plastic Injection Mould Cannula is just the beginning of what promises to be an exciting new chapter in the field of medical instrumentation.