Creating a High-Quality Plastic Injection Dustpan Mould: Everything You Need to Know

By:Admin

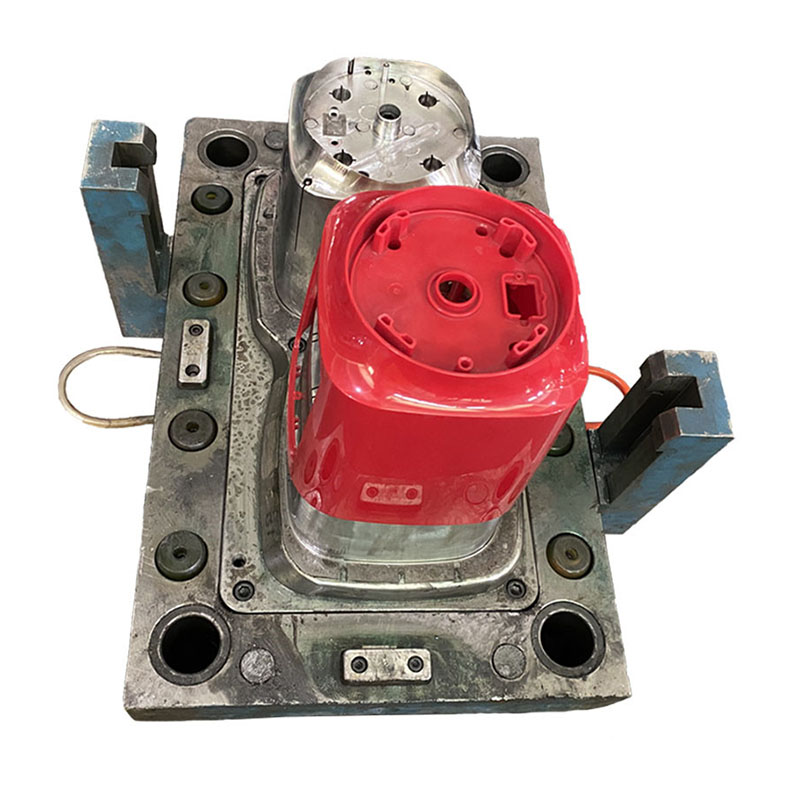

Plastic injection molding is a manufacturing process that involves injecting molten plastic into a mold to create a wide range of products, including dustpans. Plastic Injection Dustpan Mould has mastered this process, utilizing state-of-the-art equipment and techniques to deliver top-of-the-line dustpan molds to their clients.

The company prides itself on its ability to cater to the diverse needs of its clients. From design to production, Plastic Injection Dustpan Mould offers a comprehensive range of services that are tailored to meet the specific requirements of each customer. Whether it's a custom mold for a unique dustpan design or a high-volume production run, the company has the capabilities to deliver results that exceed expectations.

One of Plastic Injection Dustpan Mould's key strengths is its team of highly skilled professionals. With years of industry experience and a deep understanding of the intricacies of plastic injection molding, the company's personnel are able to provide valuable insights and recommendations to clients, ensuring the successful execution of each project. Their dedication to continuous improvement and innovation has enabled them to stay ahead of the curve and remain at the forefront of the industry.

In addition to their technical expertise, Plastic Injection Dustpan Mould is also committed to environmental sustainability. The company understands the importance of reducing waste and minimizing their environmental footprint. As such, they have implemented various initiatives to promote eco-friendly practices throughout their operations, including the use of recyclable materials and energy-efficient production methods.

Furthermore, Plastic Injection Dustpan Mould operates with a strong emphasis on quality control. Every mold undergoes rigorous testing and inspection to ensure that it meets the highest standards of durability, precision, and functionality. This unwavering commitment to quality has earned the company a solid reputation for reliability and consistency.

With a proven track record of success and a strong focus on customer satisfaction, Plastic Injection Dustpan Mould has established itself as a trusted partner for businesses seeking top-notch plastic injection molding solutions. As the demand for high-quality dustpan molds continues to rise, the company is well-positioned to meet the evolving needs of the market and drive innovation in the industry.

Looking ahead, Plastic Injection Dustpan Mould remains dedicated to pushing the boundaries of plastic injection molding technology. By investing in research and development, as well as forging strategic partnerships, the company is poised to expand its capabilities and further solidify its position as a leader in the industry.

In conclusion, Plastic Injection Dustpan Mould has proven itself to be a formidable force in the plastic injection molding sector. With its focus on superior quality, technological prowess, and customer-centric approach, the company is well-equipped to thrive in a rapidly evolving market. As it continues to grow and evolve, Plastic Injection Dustpan Mould is set to make a lasting impact on the industry for years to come.

Company News & Blog

Top Tips for Plastic Injection Molding and Moulding

Plastic Mould Injection Molding Company Leads the Way in Innovation and SustainabilityIn today's fast-paced and ever-changing world, the need for innovative and sustainable solutions has never been greater. With the rise of environmental concerns and the push for more eco-friendly products, businesses are constantly challenged to innovate and adapt. One company that has been leading the way in this regard is Plastic Mould Injection Molding Company. With a strong focus on innovation, sustainability, and customer satisfaction, the company has established itself as a leader in the industry.Plastic Mould Injection Molding Company has been at the forefront of developing cutting-edge technologies and processes to meet the growing demand for sustainable plastic products. The company's commitment to sustainability is evident in its use of eco-friendly materials and energy-efficient manufacturing practices. By investing in state-of-the-art machinery and equipment, Plastic Mould Injection Molding Company has been able to increase its production capacity while minimizing its environmental impact.One of the key factors that sets Plastic Mould Injection Molding Company apart from its competitors is its emphasis on research and development. The company has a dedicated team of engineers and designers who are constantly working to improve existing products and create new, innovative solutions. With a focus on continuous improvement, Plastic Mould Injection Molding Company has been able to stay ahead of the curve and provide its customers with high-quality, sustainable products.In addition to its focus on innovation and sustainability, Plastic Mould Injection Molding Company is also committed to providing top-notch customer service. The company works closely with its clients to understand their specific needs and requirements, and then develops customized solutions to meet those needs. Whether it's a small-scale project or a large-scale production run, Plastic Mould Injection Molding Company has the expertise and resources to deliver exceptional results.Furthermore, Plastic Mould Injection Molding Company has established a strong network of partners and suppliers to ensure that it has access to the best resources and materials. By working with trusted partners, the company is able to maintain high standards of quality and consistency in its products. This, in turn, has helped Plastic Mould Injection Molding Company build a reputation as a trusted and reliable supplier in the industry.Looking towards the future, Plastic Mould Injection Molding Company is poised to continue its leadership in innovation and sustainability. The company is constantly exploring new technologies and processes to further reduce its environmental impact and improve the quality of its products. By staying at the forefront of industry trends and customer needs, Plastic Mould Injection Molding Company is well-positioned to maintain a strong competitive edge.In conclusion, Plastic Mould Injection Molding Company is a standout in the industry, thanks to its unwavering commitment to innovation, sustainability, and customer satisfaction. As the demand for sustainable plastic products continues to grow, the company's cutting-edge technologies and dedication to quality and service will undoubtedly set it apart from the competition. With a strong focus on research and development, a robust network of partners, and a customer-centric approach, Plastic Mould Injection Molding Company is set to lead the way in shaping the future of the industry.

Revolutionizing Manufacturing: The Power of Aluminum Injection Molds

[Publication Name][Date]Aluminum Injection Mold: Revolutionizing the Manufacturing Industry[City, State] - The manufacturing industry has continuously evolved and adapted over the years to meet the demands of an ever-growing market. With advancements in technology and the introduction of innovative manufacturing processes, companies are constantly striving to stay ahead of the competition. In line with this, [Company Name], a global leader in manufacturing solutions, has recently introduced their groundbreaking Aluminum Injection Mold, an innovation set to revolutionize the industry.Aluminum injection molding is not a new concept. However, what sets [Company Name]'s Aluminum Injection Mold apart is its unparalleled quality and efficiency. The cutting-edge technology employed in the mold aims to provide manufacturers with a cost-effective and reliable solution to meet their production needs.[Company Name], a leading authority in the manufacturing domain, has been at the forefront of innovation in the industry for over [number] years. They have leveraged their years of expertise and in-depth market knowledge to develop the Aluminum Injection Mold, which offers unmatched benefits to manufacturers worldwide.One of the key advantages of [Company Name]'s Aluminum Injection Mold is its lightweight construction. Traditional molds made of steel can be heavy and cumbersome, making production processes more labor-intensive and less efficient. However, the Aluminum Injection Mold offers a lightweight alternative without compromising on strength or durability. This ensures that manufacturers can streamline their operations and enhance productivity, resulting in significant time and cost savings.In addition to its lightweight nature, the Aluminum Injection Mold also boasts excellent thermal conductivity. This property allows for faster cooling times, enabling manufacturers to increase their production rates. Coupled with the mold's exceptional dimensional stability, manufacturers can achieve superior precision and consistency in the final product. The reduction in cycle times and improved part quality contribute to higher overall efficiency and customer satisfaction.Another key feature that distinguishes [Company Name]'s Aluminum Injection Mold is its exceptional corrosion resistance. This characteristic ensures that the mold can withstand harsh conditions, including exposure to corrosive materials or high temperatures. As a result, manufacturers can minimize downtime due to mold maintenance or replacement, maximizing their production output and profitability.Moreover, [Company Name]'s Aluminum Injection Mold offers enhanced design flexibility. With rapid prototyping capabilities, manufacturers can efficiently test and iterate their designs, reducing time-to-market for new products. The mold's adaptability to complex geometries and intricate details allows manufacturers to produce parts that were previously considered challenging or impossible to manufacture.Furthermore, the Aluminum Injection Mold is environmentally friendly. Its lightweight construction reduces energy consumption during production and transportation, contributing to a lower carbon footprint. Additionally, the mold's longevity and resistance to corrosion ensure reduced waste generation and disposal, making it a sustainable choice for manufacturers looking to minimize their environmental impact.[Company Name] is committed to providing comprehensive support to manufacturers incorporating their innovative Aluminum Injection Mold into their production processes. Their experienced team of engineers and technicians offer personalized services, including mold design, optimization, and maintenance assistance. This commitment to customer satisfaction ensures seamless integration of the mold into existing manufacturing operations, resulting in optimal performance and maximum return on investment.As the market demands faster production rates, improved quality, and cost-effective solutions, [Company Name]'s Aluminum Injection Mold emerges as a game-changer in the manufacturing industry. With its lightweight construction, excellent thermal conductivity, corrosion resistance, design flexibility, and environmental advantages, this innovative mold is set to reshape the manufacturing landscape and empower companies to stay competitive in the global market.About [Company Name]:[Company Name] is a globally recognized leader in manufacturing solutions. With over [number] years of experience and expertise, they provide cutting-edge technologies and services to various industries, enabling companies to enhance their production processes and optimize their performance. Their commitment to innovation, quality, and customer satisfaction makes them a preferred partner for manufacturers worldwide.For more information or media inquiries, please contact:[Company Name]:[Contact Person and Title][Email Address][Phone Number][Website][Company Address]

Achieve Small Molding Injection for Your Business

Small Molding Injection is a leading company in the field of injection molding. With a strong focus on innovation and quality, Small Molding Injection has become a trusted partner for businesses across various industries.Founded in {}, Small Molding Injection has established itself as a leader in the field of injection molding. The company's state-of-the-art facilities and advanced technology allow them to produce high-quality products with precision and efficiency. Small Molding Injection's team of highly skilled professionals is dedicated to meeting the needs of their clients and exceeding their expectations.One of the key factors that set Small Molding Injection apart is their commitment to innovation. The company continuously invests in research and development to stay ahead of the curve and offer cutting-edge solutions to their clients. This approach has allowed Small Molding Injection to develop a diverse portfolio of products and services to meet the demands of various industries.Small Molding Injection's dedication to quality is also evident in their strict adherence to industry standards and regulations. The company's manufacturing processes are carefully monitored to ensure that each product meets the highest standards of quality and reliability. This commitment to excellence has earned Small Molding Injection the trust and loyalty of their clients.In addition to their commitment to quality and innovation, Small Molding Injection is also known for their exceptional customer service. The company's team of experts works closely with clients to understand their unique needs and provide tailored solutions that meet their specific requirements. This customer-centric approach has earned Small Molding Injection a reputation for reliability and trustworthiness.Small Molding Injection's expertise extends to a wide range of industries, including automotive, electronics, consumer goods, and more. The company's ability to adapt to the unique requirements of each industry sets them apart as a versatile and reliable partner for businesses of all sizes.Furthermore, Small Molding Injection's dedication to sustainability is evident in their environmentally friendly manufacturing processes. The company is committed to reducing its environmental footprint through the use of energy-efficient technology and sustainable materials. This dedication to sustainability has made Small Molding Injection a preferred partner for businesses looking to reduce their environmental impact.As Small Molding Injection continues to grow and expand, the company remains focused on its core values of innovation, quality, and customer satisfaction. With a proven track record of success and a strong reputation in the industry, Small Molding Injection is well-positioned to continue serving as a trusted partner for businesses seeking high-quality injection molding solutions.In conclusion, Small Molding Injection's commitment to innovation, quality, and customer satisfaction has established them as a leader in the field of injection molding. With a diverse portfolio of products and services, a customer-centric approach, and a dedication to sustainability, Small Molding Injection is well-equipped to meet the needs of businesses across various industries.

Custom Plastic Injection Mold for Power Cables: All You Need to Know

Plastic Injection Mold For Power Cables Strengthening {Company's} Commitment to Quality and Innovation{City, State, Date} - {Company} is proud to announce the introduction of a state-of-the-art plastic injection mold for power cables. This new addition to the company's production capabilities highlights {Company's} continued commitment to delivering high-quality and innovative solutions to its customers.The plastic injection mold for power cables is designed to meet the growing demand for durable and reliable power cables in various industries, including automotive, industrial, and residential applications. With this new mold, {Company} will be able to produce power cables that meet the highest industry standards for performance and reliability.{Company} has a long-standing reputation for excellence in the manufacturing of power cables, and the introduction of this new plastic injection mold further solidifies its position as a leader in the industry. The mold is equipped with advanced technology and precision engineering, allowing for the production of power cables with exceptional strength, durability, and resistance to environmental factors.In addition to enhancing the quality of its products, {Company} is also focused on the environmental impact of its operations. The new plastic injection mold for power cables is designed to minimize material waste and energy consumption, aligning with {Company's} sustainability goals. By implementing eco-friendly manufacturing practices, {Company} is demonstrating its dedication to reducing its carbon footprint and contributing to a more sustainable future.{Company's} dedication to innovation and excellence is further demonstrated through its investment in research and development. The development of the plastic injection mold for power cables is the result of extensive research and testing, ensuring that the final product meets the rigorous standards set by {Company}. This commitment to continuous improvement allows {Company} to adapt to evolving market demands and stay ahead of the competition.The plastic injection mold for power cables is just one example of {Company's} ongoing efforts to expand its product offerings and deliver solutions that meet the diverse needs of its customers. By offering a comprehensive range of power cables and related products, {Company} aims to be the go-to partner for businesses seeking quality, reliability, and innovation in their supply chain.{Company} has a rich history of serving customers across various industries, including automotive, aerospace, telecommunications, and more. The addition of the plastic injection mold for power cables further strengthens {Company's} position as a trusted supplier and partner to companies of all sizes and sectors.As demand for power cables continues to grow, {Company} is well-positioned to meet the needs of its customers with the introduction of the plastic injection mold. With this new capability, {Company} is poised to play a significant role in shaping the future of power cable manufacturing and contributing to the advancement of technology across industries.The introduction of the plastic injection mold for power cables is a testament to {Company's} unwavering dedication to quality, innovation, and sustainability. As the company continues to expand its capabilities and product offerings, customers can expect nothing less than excellence from {Company}.For more information about {Company} and its plastic injection mold for power cables, please visit {company website} or contact {company representative} at {contact information}.In conclusion, the introduction of the plastic injection mold for power cables is a significant milestone for {Company} and demonstrates its commitment to delivering high-quality and innovative solutions to its customers. With this new capability, {Company} is poised to meet the growing demand for power cables and play a leading role in shaping the future of the industry.

Plastic Body Parts Injection Moulding for Scooters

[Company Name] is excited to announce its latest venture into the world of injection moulding for scooter plastic body parts. As a leading manufacturer in the scooter industry, [Company Name] has consistently pushed the boundaries of innovation and quality, and the addition of injection moulding capabilities further solidifies their commitment to providing top-of-the-line products to their customers.Injection moulding is a manufacturing process that involves injecting molten material into a mould to create a part or product. This process is widely used in the production of plastic parts for various industries, including automotive, electronics, and consumer goods. By adding injection moulding to their arsenal of manufacturing techniques, [Company Name] is poised to elevate the quality and efficiency of their scooter plastic body parts production.With the new injection moulding capabilities, [Company Name] will be able to produce scooter plastic body parts with greater precision and consistency. The process allows for complex shapes and designs to be achieved with minimal waste, resulting in cost-effective production and high-quality end products. This advancement in manufacturing technology will enable [Company Name] to meet the increasing demand for their scooter plastic body parts while maintaining the highest standards of quality.In addition to the technical advantages, the implementation of injection moulding for scooter plastic body parts aligns with [Company Name]'s commitment to sustainability. The process produces minimal waste and allows for the efficient use of materials, reducing the environmental impact of production. As a company that values environmental responsibility, [Company Name] is proud to integrate sustainable manufacturing practices into their operations.To ensure the success of this new venture, [Company Name] has invested in state-of-the-art injection moulding equipment and has trained their team of engineers and technicians in the intricacies of the process. The company has also partnered with leading experts in injection moulding technology to further enhance their capabilities and stay at the forefront of industry advancements.The introduction of injection moulding for scooter plastic body parts is a testament to [Company Name]'s dedication to innovation and continuous improvement. By expanding their manufacturing capabilities, [Company Name] is not only strengthening their position in the market but also setting new standards for quality and efficiency in the scooter industry.In closing, the addition of injection moulding for scooter plastic body parts is a significant milestone for [Company Name], marking a new era of manufacturing excellence and sustainability. With this advancement, [Company Name] is poised to deliver even greater value to their customers and reaffirm their status as a leader in the scooter industry. The company looks forward to the positive impact this new technology will have on their business and the industry as a whole.

Discover the Leading ABS Plastic Injection China Mould Manufacturer

Title: Leading Manufacturer of ABS Plastic Injection Molds in China Sets New Industry StandardsIntroduction: In the ever-growing global market, the demand for high-quality plastic products is constantly on the rise. One of the key factors contributing to this increasing demand is the versatility and durability of ABS plastic. It is widely used in various industries, including automotive, electronics, and consumer goods. Recognizing this demand, a renowned Chinese manufacturer specializing in ABS plastic injection molds has emerged as a dominant force in the industry. With their cutting-edge technology, state-of-the-art facilities, and commitment to innovation, they have set new standards for excellence in the production of injection molds.Body:1. Company Background and Development:Established in the heart of China's manufacturing hub, this leading ABS plastic injection mold manufacturer has decades of experience in the industry. Their commitment to delivering high-quality products and exceptional customer service has helped them gain a strong reputation both in China and internationally. The company has consistently invested in research and development to improve their manufacturing processes and stay ahead of the competition.2. Technological Advancements:This manufacturer stands out from the competition due to its focus on technological advancements. Their state-of-the-art facilities are equipped with the latest machinery and tools, enabling them to produce injection molds of diverse sizes and complexities. By employing computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies, the company ensures precision and accuracy in every mold they produce. This dedication to technology-driven manufacturing sets them apart from traditional mold manufacturers.3. Excellent Quality Control:Quality control is a top priority for this manufacturer. They adhere to stringent standards and maintain a comprehensive quality management system throughout the production process. This includes careful material selection, rigorous testing, and continuous monitoring to ensure the molds meet or exceed customer expectations. By employing a team of experienced engineers and technicians, they conduct thorough inspections at every stage of production, guaranteeing the highest level of quality and reliability.4. Versatile Application and Customization:The versatility of ABS plastic injection molds allows them to be used across a wide range of industries. From automotive parts to consumer electronics and household appliances, this manufacturer has the expertise to develop molds that meet the unique specifications of each customer. Their team of skilled professionals collaborates closely with clients to understand their specific requirements. With this collaborative approach, they offer cost-effective solutions tailored to the client's needs, ensuring optimum performance and efficiency.5. Commitment to Environmental Responsibility:This leading Chinese manufacturer also places great emphasis on environmental responsibility. They actively adopt sustainable practices during the manufacturing process, including the use of eco-friendly materials and recycling waste products. By making conscious efforts to minimize their environmental impact, they contribute to a greener future and uphold their social responsibilities as a manufacturer.6. Expansion and International Reach:Despite being based in China, the manufacturer has achieved a global presence and serves customers from around the world. Their commitment to high-quality products, timely delivery, and competitive pricing has garnered them a loyal customer base. They continue to expand their operations, establishing strong partnerships with international companies and distributors. Through their exceptional customer support and dedication to customer satisfaction, this manufacturer has gained recognition and respect on both the domestic and international stages.Conclusion:With an unwavering commitment to technological innovation, exceptional product quality, and sustainable manufacturing practices, this Chinese ABS plastic injection mold manufacturer has become the industry benchmark. Their ability to customize molds for a range of applications, combined with their expansive international reach, positions them as a leader in the global market. As the demand for ABS plastic products continues to grow, this manufacturer's dedication to excellence and customer-centric approach ensures they will retain their position at the forefront of the industry.

A complete guide to injection molding techniques

Injection Mold Or Injection Molding is a widely used manufacturing process for creating a variety of products, from plastic components to metal parts. It involves injecting molten material into a mold, which is then cooled and solidified to form the desired shape. This process is used in a wide range of industries, including automotive, aerospace, electronics, and medical devices.One company that has excelled in the field of Injection Mold Or Injection Molding is {}. {} has been at the forefront of innovation and excellence in this industry for over twenty years. With a strong emphasis on quality, precision, and efficiency, {} has established itself as a leading provider of injection molding services.Injection Mold Or Injection Molding process at {} is a highly controlled and precise operation. The company utilizes state-of-the-art equipment and advanced technologies to ensure that every product meets the highest standards of quality and accuracy. With a team of experienced engineers and technicians, {} is able to provide custom solutions for a wide range of manufacturing needs.{} is capable of handling a wide variety of materials, including various types of plastics, metals, and composites. This allows the company to create custom solutions for a diverse set of industries and applications. Whether it's producing intricate plastic components for the automotive industry or creating precision metal parts for aerospace applications, {} has the expertise and capabilities to deliver high-quality products.In addition to its manufacturing capabilities, {} also offers design and engineering services to help clients bring their ideas to life. With a focus on innovation and collaboration, the company works closely with its clients to develop custom solutions that meet their specific requirements. Whether it's creating a new product from scratch or optimizing an existing design for manufacturability, {} has the expertise and resources to make it happen.One of the key advantages of Injection Mold Or Injection Molding is its ability to produce high volumes of parts with excellent consistency and repeatability. This makes it an ideal solution for mass production and large-scale manufacturing needs. Whether it's producing small, intricate components or large, complex parts, {} has the capacity and expertise to deliver reliable, high-quality products on a consistent basis.As a provider of injection molding services, {} is committed to sustainability and environmental responsibility. The company utilizes efficient manufacturing processes and sustainable materials to minimize its environmental impact. This commitment to sustainability not only benefits the environment, but also helps clients meet their own sustainability goals and requirements.With a strong track record of delivering high-quality products and a commitment to innovation and excellence, {} is well-positioned to continue its leadership in the field of Injection Mold Or Injection Molding. As the demand for custom manufacturing solutions continues to grow, {} is dedicated to providing the highest level of service and quality to its clients.In conclusion, Injection Mold Or Injection Molding is a critical manufacturing process used in a wide range of industries. {} has established itself as a leading provider of injection molding services, with a strong emphasis on quality, precision, and efficiency. With a focus on innovation and collaboration, {} is well-equipped to meet the diverse needs of its clients and deliver high-quality products on a consistent basis.

Ultimate Guide to Precision Plastic Injection Molds: Everything You Need to Know

[Company Name], a Leader in Precision Plastic Injection Molds, Revolutionizes the Manufacturing Industry[date]In today's competitive manufacturing industry, it is imperative for companies to stay at the forefront of technological advancements and provide high-quality products efficiently. Without a doubt, Precision Plastic Injection Mold (need remove brand name) has proven to be an influential player in this domain, setting industry standards and driving innovation. With a rich history of providing exceptional plastic injection molds, (Company Name) continues to revolutionize the manufacturing industry.Established in (year), (Company Name) has grown from a small operation to become a renowned leader in precision plastic injection molds. With expertise in designing and producing high-performance molds, the company has successfully met the ever-increasing demands of its clients in multiple sectors, including automotive, consumer electronics, medical devices, and industrial applications.What sets (Company Name) apart is its commitment to continuous improvement and innovation, ensuring that it remains ahead of the curve. The company's cutting-edge facilities are equipped with state-of-the-art manufacturing technologies, including Computer-Aided Design (CAD) software, Computer Numerical Control (CNC) machining centers, and advanced measurement equipment. This investment in modern technology helps (Company Name) to efficiently produce molds with intricate designs, high precision, and optimal performance.Furthermore, (Company Name)'s team of experienced engineers and designers collaborates closely with clients to understand their specific requirements and translate them into customized mold solutions. By employing a customer-centric approach, the company ensures that its molds meet the highest standards and are tailored to the unique needs of each application. With their expertise and creativity, (Company Name) consistently delivers molds that optimize production efficiency, reduce costs, and enhance product quality.Quality is of paramount importance at (Company Name). The company follows strict quality control measures at every stage of the manufacturing process, adhering to international standards and certifications. Molds manufactured by (Company Name) undergo rigorous testing to guarantee their reliability and durability. This commitment to quality has earned the company a stellar reputation as a trusted partner among its global clientele.Sustainability is another key focus for (Company Name). Recognizing the growing concern for environmental conservation, the company adopts eco-friendly practices throughout its operations. By utilizing recyclable materials and optimizing energy consumption, (Company Name) minimizes its environmental impact without compromising on the quality and performance of its molds. This dedication to sustainable manufacturing contributes to a greener future for the industry and the world.In line with its commitment to innovation, (Company Name) also invests heavily in research and development. The company's dedicated R&D team continuously explores new materials, manufacturing techniques, and design concepts to pioneer groundbreaking solutions. By staying at the forefront of technology, (Company Name) consistently introduces advanced mold designs with enhanced features, optimized cycle times, and reduced production costs, giving its clients a competitive edge in the market.With an impressive track record and an unwavering commitment to excellence, (Company Name) is poised to lead the manufacturing industry into the future. As the demand for precision plastic injection molds continues to grow, the company is well-positioned to meet these challenges head-on, providing industry-leading solutions that drive productivity and efficiency.In conclusion, (Company Name) has solidified itself as a frontrunner in the precision plastic injection mold industry, delivering innovative solutions that redefine manufacturing processes. With cutting-edge technology, a customer-centric approach, and a focus on quality and sustainability, the company continues to push boundaries and set new standards. As the manufacturing industry evolves, (Company Name) remains at the forefront of progress, shaping the future of precision plastic injection molds.

Ultimate Guide to Plastic Injection Molding PVC Techniques and Benefits

[Company Name] Leads the Way in Plastic Injection Molding with PVCWith the increasing demand for high-quality plastic products in various industries, [Company Name] stands out as a leader in the field of plastic injection molding. The company has established a reputable name for itself by offering innovative solutions and top-notch products, particularly in the use of PVC - a versatile and durable material.[Company Name] has been in the plastics manufacturing industry for over [Number] years, and has emerged as a trusted partner for businesses looking for custom plastic injection molding solutions. The company's state-of-the-art facility and team of experienced engineers and technicians enable them to offer a wide range of services, including design assistance, mold making, and production of precision plastic components.One of the key aspects that set [Company Name] apart from its competitors is its expertise in working with PVC. PVC, or polyvinyl chloride, is a widely used thermoplastic polymer that is known for its excellent properties such as strength, chemical resistance, and affordability. [Company Name] has mastered the art of plastic injection molding with PVC, and can produce a diverse array of products using this material. From consumer goods and automotive components to medical devices and electrical parts, [Company Name] has the capability to fulfill the diverse needs of its clients across various industries.In addition to its expertise in PVC injection molding, [Company Name] prides itself on its commitment to sustainability and environmental responsibility. The company is dedicated to using recycled materials and minimizing waste in its production processes. By adopting eco-friendly practices, [Company Name] not only reduces its environmental footprint but also helps its clients meet their sustainability goals.Furthermore, [Company Name] is constantly investing in the latest technology and equipment to stay ahead of the curve in the rapidly evolving plastics industry. The company's dedication to continuous improvement and innovation ensures that it stays at the forefront of plastic injection molding, offering its clients the most cutting-edge solutions."We are passionate about delivering the highest quality products to our clients," says [Spokesperson's Name], the CEO of [Company Name]. "Our commitment to excellence and our expertise in PVC injection molding have positioned us as a preferred partner for businesses seeking reliable and efficient plastic manufacturing solutions."Through its strong emphasis on quality, customer satisfaction, and environmental stewardship, [Company Name] has established itself as a leading force in the plastic injection molding industry. With its focus on PVC as a versatile and durable material, [Company Name] is well-equipped to meet the evolving needs of its clients across diverse industries.As the demand for high-quality plastic products continues to grow, [Company Name] remains dedicated to providing innovative and sustainable solutions through its expertise in PVC injection molding. As the company looks to the future, it is poised to continue leading the way in the plastics manufacturing industry, setting new standards for excellence and reliability.

Top Plastic Mold Injection Service for Quality Manufacturing

[Your Company Name] Offers Cutting-Edge Plastic Mold Injection Service, Revolutionizing Manufacturing Processes[City, Date] - [Your Company Name], a leading provider of advanced manufacturing solutions, is at the forefront of the industry with its innovative plastic mold injection service. Through state-of-the-art technology, skilled professionals, and a commitment to delivering exceptional quality, [Your Company Name] is revolutionizing the way plastic products are manufactured.Plastic mold injection has become a fundamental manufacturing method across various industries, enabling the production of complex and intricate components. With [Your Company Name]'s expertise in this sector, clients can enjoy a seamless and efficient manufacturing process with reduced lead times and enhanced product performance."At [Your Company Name], we understand the ever-evolving demands of the manufacturing industry, which is why we continuously invest in cutting-edge technology and highly-skilled professionals. Our plastic mold injection service allows us to offer our clients unparalleled precision, speed, and reliability," says [Company Spokesperson].Guided by a commitment to excellence, [Your Company Name] employs a comprehensive approach to plastic mold injection, beginning with thorough consultation services. By collaborating closely with clients, the company's experts ensure a tailored solution that meets their exact requirements. Through meticulous design analysis and prototyping, potential design flaws and gaps in functionality are identified, allowing for valuable modifications before the manufacturing process begins.State-of-the-art facilities and advanced machinery enable [Your Company Name] to deliver unrivaled manufacturing capabilities. Equipped with a wide range of plastic material options, including ABS, PET, HDPE, PP, and many others, the company's expert engineers ensure that each component is produced to the highest standards. Surface finishes such as texture, gloss, and multi-color options provide further customization possibilities for clients seeking to differentiate their products in the market.A key advantage of [Your Company Name]'s plastic mold injection service is its ability to deliver products in large volumes, while still maintaining exceptional quality control. Through careful monitoring and rigorous inspection processes, any defects or imperfections are identified and rectified promptly, minimizing waste and ensuring optimum productivity.By integrating robotic automation into its manufacturing processes, [Your Company Name] has further enhanced its efficiency and precision. This automation allows for high-speed production, reducing the turnaround time for projects and ensuring on-time delivery for clients.Environmental sustainability is also a primary focus for [Your Company Name]. The company employs eco-friendly practices throughout its manufacturing operations, including responsible waste management, recycling initiatives, and the utilization of energy-efficient machinery. By prioritizing sustainability, [Your Company Name] actively contributes to the preservation of our planet for present and future generations.The extensive expertise and industry knowledge of [Your Company Name]'s team sets them apart from the competition. From the initial consultation to the final delivery of the product, the company's professionals are dedicated to providing unparalleled customer service and support. Their commitment to building long-term relationships, paired with their technical prowess, ensures that clients receive not only high-quality components but also a seamless and enjoyable experience.With its cutting-edge plastic mold injection service, [Your Company Name] is driving innovation in the manufacturing industry. By embracing technology, employing skilled professionals, and prioritizing client satisfaction, the company continues to exceed expectations and redefine the possibilities of plastic product manufacturing.About [Your Company Name] (need remove brand name):[Your Company Name] is a leading provider of advanced manufacturing solutions, specializing in plastic mold injection. With state-of-the-art facilities and a team of highly-skilled professionals, the company delivers exceptional quality, precision, and efficiency for clients across various industries. [Your Company Name]'s commitment to innovation, sustainability, and customer satisfaction has firmly established it as a trusted name in the manufacturing sector.For media inquiries, please contact:[Company Spokesperson][Your Company Name]Phone: [Phone Number]Email: [Email Address]Website: [Website URL]