Custom Plastic Injection Molding Services for Creating Quality Plastic Parts

By:Admin

One company that has made a significant impact in the plastic parts injection molding industry is {}. This company has established itself as a leader in the field, offering a wide range of injection molding services to meet the needs of its diverse clientele. With state-of-the-art facilities and a team of experienced professionals, {} has consistently delivered top-quality plastic parts to its customers, earning a reputation for excellence and reliability.

{} specializes in providing custom injection molding solutions for a variety of applications, including automotive, electronics, medical devices, consumer goods, and more. The company's commitment to innovation and customer satisfaction has allowed it to forge strong partnerships with leading brands and businesses, positioning itself as a preferred supplier for plastic parts and components.

The injection molding process employed by {} allows for the production of complex plastic parts with remarkable accuracy and consistency. By utilizing advanced machinery and tooling, the company is able to manufacture parts with tight tolerances and intricate geometries, meeting the exact specifications of its clients. This precision and attention to detail have made {} a trusted name in the industry, attracting businesses seeking high-quality plastic components for their products.

In addition to its advanced manufacturing capabilities, {} also places a strong emphasis on sustainability and environmental responsibility. The company has implemented eco-friendly practices and processes into its operations, striving to minimize waste and reduce its carbon footprint. By using recyclable materials and optimizing energy usage, {} is dedicated to promoting a greener approach to injection molding, aligning with the growing global focus on sustainability.

Furthermore, {} is committed to continuous improvement and innovation, investing in research and development to stay ahead of industry trends and technological advancements. The company consistently explores new materials, processes, and techniques to enhance its capabilities and offer cutting-edge solutions to its customers. By staying at the forefront of innovation, {} is well-positioned to address the evolving needs of the market and deliver innovative plastic parts to its clients.

In response to the increasing demand for custom plastic parts, {} has expanded its production capacity and capabilities, ensuring that it can accommodate large-scale orders and tight deadlines. The company's ability to efficiently produce high volumes of plastic parts without compromising quality has made it a preferred supplier for businesses requiring mass production of components and products.

With a customer-centric approach and a dedication to excellence, {} has earned the trust and loyalty of its clients, who rely on the company for their injection molding needs. By offering personalized service, fast turnaround times, and uncompromising quality, {} has established itself as a go-to partner for companies seeking reliable plastic parts manufacturing.

As the demand for custom plastic parts continues to grow, companies like {} will play a crucial role in meeting the industry's needs and driving innovation. With its advanced capabilities, commitment to sustainability, and customer-focused approach, {} is well-positioned to remain a leader in the plastic parts injection molding industry, serving as a trusted partner for businesses across various sectors.

Company News & Blog

Discover the Leading ABS Plastic Injection China Mould Manufacturer

Title: Leading Manufacturer of ABS Plastic Injection Molds in China Sets New Industry StandardsIntroduction: In the ever-growing global market, the demand for high-quality plastic products is constantly on the rise. One of the key factors contributing to this increasing demand is the versatility and durability of ABS plastic. It is widely used in various industries, including automotive, electronics, and consumer goods. Recognizing this demand, a renowned Chinese manufacturer specializing in ABS plastic injection molds has emerged as a dominant force in the industry. With their cutting-edge technology, state-of-the-art facilities, and commitment to innovation, they have set new standards for excellence in the production of injection molds.Body:1. Company Background and Development:Established in the heart of China's manufacturing hub, this leading ABS plastic injection mold manufacturer has decades of experience in the industry. Their commitment to delivering high-quality products and exceptional customer service has helped them gain a strong reputation both in China and internationally. The company has consistently invested in research and development to improve their manufacturing processes and stay ahead of the competition.2. Technological Advancements:This manufacturer stands out from the competition due to its focus on technological advancements. Their state-of-the-art facilities are equipped with the latest machinery and tools, enabling them to produce injection molds of diverse sizes and complexities. By employing computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies, the company ensures precision and accuracy in every mold they produce. This dedication to technology-driven manufacturing sets them apart from traditional mold manufacturers.3. Excellent Quality Control:Quality control is a top priority for this manufacturer. They adhere to stringent standards and maintain a comprehensive quality management system throughout the production process. This includes careful material selection, rigorous testing, and continuous monitoring to ensure the molds meet or exceed customer expectations. By employing a team of experienced engineers and technicians, they conduct thorough inspections at every stage of production, guaranteeing the highest level of quality and reliability.4. Versatile Application and Customization:The versatility of ABS plastic injection molds allows them to be used across a wide range of industries. From automotive parts to consumer electronics and household appliances, this manufacturer has the expertise to develop molds that meet the unique specifications of each customer. Their team of skilled professionals collaborates closely with clients to understand their specific requirements. With this collaborative approach, they offer cost-effective solutions tailored to the client's needs, ensuring optimum performance and efficiency.5. Commitment to Environmental Responsibility:This leading Chinese manufacturer also places great emphasis on environmental responsibility. They actively adopt sustainable practices during the manufacturing process, including the use of eco-friendly materials and recycling waste products. By making conscious efforts to minimize their environmental impact, they contribute to a greener future and uphold their social responsibilities as a manufacturer.6. Expansion and International Reach:Despite being based in China, the manufacturer has achieved a global presence and serves customers from around the world. Their commitment to high-quality products, timely delivery, and competitive pricing has garnered them a loyal customer base. They continue to expand their operations, establishing strong partnerships with international companies and distributors. Through their exceptional customer support and dedication to customer satisfaction, this manufacturer has gained recognition and respect on both the domestic and international stages.Conclusion:With an unwavering commitment to technological innovation, exceptional product quality, and sustainable manufacturing practices, this Chinese ABS plastic injection mold manufacturer has become the industry benchmark. Their ability to customize molds for a range of applications, combined with their expansive international reach, positions them as a leader in the global market. As the demand for ABS plastic products continues to grow, this manufacturer's dedication to excellence and customer-centric approach ensures they will retain their position at the forefront of the industry.

Key Insights and Advancements in Plastic Injection Molding

[Company Name], a Leading Provider of Plastic Injection Molds, Continues to Pave the Way in Innovative Manufacturing Solutions[City, Date] - Plastic Injection Mold (PIM) production has been an essential aspect of the manufacturing industry for many years. It plays a pivotal role in meeting the demand for high-quality plastic products across various sectors. A company at the forefront of delivering cutting-edge plastic injection molds is [Company Name].With over [number of years] years of industry experience, [Company Name] has established itself as a trusted provider of top-notch plastic injection molds. Their commitment to innovation and customer satisfaction has placed them in a league of their own, consistently delivering exceptional results.Headquartered in [City], [Company Name] boasts a state-of-the-art manufacturing facility equipped with the latest technology and machinery. This allows them to offer an extensive range of plastic injection mold services to cater to the diverse needs of their clients.One of the key factors that sets [Company Name] apart from its competitors is their team of highly skilled and experienced engineers and technicians. These professionals possess a deep understanding of the intricacies of plastic injection molding and are adept at designing molds that optimize both efficiency and quality.By collaborating closely with clients, [Company Name] ensures that the molds they produce align perfectly with the specific requirements of the end product. They leverage cutting-edge software tools and a meticulous design process to craft molds that are not only durable but also capable of producing consistently high-quality products.In addition to their expertise in mold design, [Company Name] also places utmost importance on using high-quality materials. They source materials from trusted suppliers, ensuring that every mold exhibits excellent durability and longevity. By prioritizing the use of superior materials, [Company Name] ensures that their molds can withstand the demanding requirements of high-volume production.One of the standout features of [Company Name] is their commitment to keeping abreast of the latest industry trends and technological advancements. They continually invest in research and development, exploring new materials, processes, and technologies to stay ahead of the curve. This dedication to innovation allows them to offer their clients the most cutting-edge solutions, enhancing productivity and efficiency.[Company Name]'s dedication to customer satisfaction is reflected in their comprehensive after-sales support. They offer ongoing technical assistance and maintenance services to ensure the molds continue to perform optimally throughout their lifecycle. This commitment to building long-term partnerships enables [Company Name] to become a trusted collaborator for manufacturing companies worldwide.As a market leader in plastic injection mold production, [Company Name] has an impressive portfolio of successful projects across diverse industries such as automotive, healthcare, consumer goods, and more. Their molds have played a crucial role in shaping countless products that have become integral parts of our daily lives.With an unwavering commitment to quality, innovation, and customer satisfaction, [Company Name] continues to pave the way in the plastic injection mold industry. By combining their technical expertise, state-of-the-art facility, and keen eye for industry trends, they are pushing the boundaries of what is possible in plastic manufacturing.[Company Name]'s dedication to delivering top-notch plastic injection molds has earned them the trust and confidence of clients worldwide. As they strive to set new industry standards, there is no doubt that [Company Name] will continue to be at the forefront of the global plastic injection mold market.About [Company Name]:[Company Name] is a renowned provider of plastic injection molds, offering a comprehensive range of services to clients across various industries. With a focus on innovation, superior materials, and excellent customer support, [Company Name] has established itself as a trusted partner for manufacturing companies worldwide. For more information, please visit their website at [Company Website].Press Contact:[Name][Title][Phone Number][Email Address]

Custom Plastic Injection Molding Service Offers Top-notch Mould Solutions

Title: Industry-Leading Plastic Injection Molding Service Revolutionizes Manufacturing ProcessesIntroduction:In an era of constant innovation and technological advancements, one company has emerged as a frontrunner in the field of custom plastic injection molding services. Located in [Company's Location], this industry-leading firm has been offering a wide range of cutting-edge solutions to meet the diverse manufacturing needs of clients across various industries. With its state-of-the-art facilities, highly skilled workforce, and unwavering commitment to quality, the company has established itself as a go-to partner for businesses seeking reliable and efficient plastic injection molding services.Body:1. Overview of the Company:[Company Name], a prominent player in the plastic injection molding industry, has been providing exceptional solutions and value-added services since its establishment. Founded with a vision to revolutionize the manufacturing landscape, the company has continuously invested in infrastructure and equipped its facilities with the latest technology to stay ahead of the competition. With a strong focus on quality, precision, and customer satisfaction, [Company Name] has become synonymous with excellence in plastic injection molding.2. Extensive Range of Services:At [Company Name], they understand that every client's project is unique. Therefore, they offer a diverse range of services to cater to various manufacturing requirements. From prototype development to large-scale production runs, their capabilities cover a wide spectrum of industries, including automotive, electronics, medical, consumer goods, and more. Whether it is manufacturing intricate components or producing complete assembly parts, the company delivers efficient and cost-effective solutions tailored to the specific needs of each client.3. Cutting-Edge Technology and Facilities:One of the key factors behind the success of [Company Name] is its continuous investment in advanced technology. The company utilizes state-of-the-art plastic injection molding machines and tools to ensure accuracy, consistency, and superior quality in all produced parts. Moreover, their facilities strictly adhere to international standards, enabling them to maintain exceptional levels of cleanliness, hygiene, and safety. The company's commitment to maintaining a technologically advanced infrastructure is a testament to their dedication to providing exemplary services.4. Expertise and Skilled Workforce:The skilled workforce at [Company Name] combines years of experience with extensive knowledge of plastic injection molding techniques. From design and engineering to production and quality control, their experts work collaboratively with clients to optimize designs, enhance manufacturability, and achieve desired outcomes. The team's proficiency in working with different materials, such as ABS, PC, PP, and more, allows them to produce components that meet the highest industry standards with precision and consistency.5. Strict Quality Control Measures:Emphasizing quality as a paramount focus, all manufacturing processes at [Company Name] are subjected to rigorous quality control measures. The company adheres to internationally recognized quality management systems, such as ISO 9001, to ensure that the final products exceed customer expectations. From material selection to mold design and from injection molding to final inspection, each step undergoes thorough checks and balances to guarantee the delivery of defect-free parts.6. Commitment to Sustainability:In an era marked by increased environmental awareness, [Company Name] recognizes the importance of sustainable practices. The company takes pride in its efficient use of resources, recycling programs, and waste reduction strategies. By employing eco-friendly materials and optimizing production processes, they minimize the impact on the environment while ensuring the highest quality of their products. This commitment to sustainable manufacturing makes [Company Name] a responsible and socially conscious player in the industry.Conclusion:[Company Name]'s custom plastic injection molding services have democratized manufacturing processes, enabling businesses of all sizes to benefit from cost-effective solutions and superior product quality. By leveraging cutting-edge technology, maintaining stringent quality control measures, and fostering a team of skilled experts, the company has set a benchmark for the industry. With unparalleled expertise and a commitment to customer satisfaction, [Company Name] is poised to shape the future of plastic injection molding, propelling the manufacturing sector into an era of unprecedented possibilities.

Top quality injection molding die moulds for sale - find out more!

Introduction:Injection molding is a manufacturing process used for producing parts by injecting molten material into a mold. This process is widely used in the production of various products, including automotive parts, packaging, and consumer goods. One of the key components in injection molding is the die mold, which plays a crucial role in determining the quality and precision of the final products. In recent news, the renowned company {}, specializing in the design and production of injection molding die molds, has made significant advancements in their technology, which are set to revolutionize the industry.Revolutionizing Injection Molding Die Molds:{}, a leader in the field of injection molding technology, has made groundbreaking developments in their die mold designs. These advancements come as a result of years of research and development, as well as a deep understanding of the needs and challenges faced by manufacturers in the industry. The company has successfully developed a new range of die molds that offer improved precision, durability, and efficiency, setting a new standard for the industry.One of the key innovations in the new die molds is the integration of advanced materials and manufacturing techniques. By utilizing high-quality materials and state-of-the-art manufacturing processes, {} has been able to significantly enhance the performance and longevity of their die molds. This means that manufacturers can expect higher productivity and lower maintenance costs, ultimately leading to improved profitability and competitiveness in the market.Furthermore, {} has introduced new design features that enable greater flexibility and customization in the production process. The company understands the diverse needs of manufacturers in different industries, and as such, they have developed die molds that can be easily adapted to various production requirements. Whether it is complex geometries, precise specifications, or unique material properties, {} has the capability to provide tailored solutions that meet the exact needs of their customers.The advancements in the die mold technology also address the growing demand for sustainability and environmental responsibility in the manufacturing sector. By optimizing the design and production processes, {} has been able to reduce material waste, energy consumption, and emissions, contributing to a more sustainable and eco-friendly manufacturing practice. This is a commendable achievement in an industry that is constantly seeking ways to minimize its environmental impact.Partnership and Collaboration:In order to bring these groundbreaking advancements to the market, {} has been actively seeking partnerships and collaborations with manufacturers and industry experts. By working closely with their customers, the company aims to gain valuable insights into the specific challenges and requirements faced by manufacturers, allowing them to further refine and optimize their die mold designs. Through these collaborative efforts, {} is able to provide tailored solutions that perfectly align with the needs of their customers, ensuring maximum satisfaction and success in their production processes.Potential Impact:The advancements made by {} in the field of injection molding die molds are expected to have a substantial impact on the industry as a whole. Manufacturers can look forward to greater efficiency, precision, and versatility in their production processes, ultimately leading to improved product quality and reduced time-to-market. With the new die molds from {}, manufacturers will have the tools they need to stay ahead of the competition and meet the ever-increasing demands of the market.Conclusion:In conclusion, the developments made by {} in the design and production of injection molding die molds are set to revolutionize the industry. With their advanced technology, high-quality materials, and commitment to customer satisfaction, {} is paving the way for a new era of innovation and excellence in injection molding. Manufacturers can now look forward to a future of greater efficiency, flexibility, and sustainability, thanks to the groundbreaking advancements made by {}.

Custom Injection Molding and Part Injection Mould in China

China Custom Injection Molding and Part Injection Mould, a major player in the injection molding industry, has been making waves in the global market with its high-quality products and advanced technology. The company, based in China, has built a strong reputation for providing custom injection molding solutions to a wide range of industries including automotive, medical, consumer goods, and electronics.With a commitment to innovation and customer satisfaction, China Custom Injection Molding and Part Injection Mould has been at the forefront of developing cutting-edge injection molding technology. The company’s state-of-the-art manufacturing facilities are equipped with the latest machinery and tools to ensure precision and efficiency in producing high-quality injection molded parts.One of the key factors that sets China Custom Injection Molding and Part Injection Mould apart from its competitors is its dedication to meeting the specific needs of its clients. The company’s team of experienced engineers and designers work closely with customers to understand their unique requirements and provide tailored solutions to meet their exact specifications.In addition to custom injection molding, China Custom Injection Molding and Part Injection Mould also specializes in part injection mold manufacturing. The company’s expertise in mold design and production ensures that customers receive the best possible solutions for their injection molding needs. With a focus on precision engineering and quality control, China Custom Injection Molding and Part Injection Mould consistently delivers top-notch injection molded parts to its global clientele.The company’s commitment to quality is further evident in its adherence to strict manufacturing standards and practices. China Custom Injection Molding and Part Injection Mould is certified to ISO 9001, demonstrating its dedication to maintaining the highest levels of quality and reliability in its products and services.China Custom Injection Molding and Part Injection Mould’s dedication to excellence has earned it a solid reputation in the global market. By continually investing in research and development, the company stays ahead of the curve in terms of technological advancements and industry trends. This forward-thinking approach allows China Custom Injection Molding and Part Injection Mould to remain a trusted partner for clients seeking high-quality injection molding solutions.As the demand for custom injection molding continues to grow, China Custom Injection Molding and Part Injection Mould is well-positioned to capitalize on this trend. The company’s proven track record, commitment to quality, and dedication to customer satisfaction set it apart as a leader in the injection molding industry. With a focus on innovation and excellence, China Custom Injection Molding and Part Injection Mould is poised to continue making significant contributions to the global manufacturing sector.In conclusion, China Custom Injection Molding and Part Injection Mould’s dedication to providing high-quality custom injection molding solutions has solidified its position as a leader in the industry. With a focus on innovation, precision, and customer satisfaction, the company continues to set the standard for excellence in injection molding. As the demand for custom injection molding solutions continues to rise, China Custom Injection Molding and Part Injection Mould is well-prepared to meet the needs of its global clientele and maintain its reputation as a trusted provider of high-quality injection molded parts.

High-Quality Moulds for Plastic Injection: A Comprehensive Guide

Moulds for Plastic Injection: A Vital Component of ManufacturingIn the world of manufacturing, the production of high-quality plastic parts and components is essential for a wide range of industries. From automotive and electronics to consumer products and medical devices, the demand for precision-molded plastic parts continues to grow. At the heart of this process are the moulds for plastic injection, which play a crucial role in shaping and forming plastic materials into the desired products. One company that has been at the forefront of producing these moulds is {Company}, a leading manufacturer and supplier of precision moulds for plastic injection.{Company} has established itself as a trusted and reliable partner for companies looking to produce high-quality plastic parts. With a strong focus on precision engineering and a commitment to innovation, the company has built a reputation for delivering state-of-the-art moulds that meet the exacting standards of its customers.The process of plastic injection moulding begins with the design and creation of the mould, which serves as the tool for shaping the molten plastic into the desired form. {Company} leverages advanced design and manufacturing technologies to produce moulds that are tailored to the specific requirements of each customer. Whether it's a complex geometric shape or a tiny yet intricate component, {Company} has the expertise and capabilities to deliver moulds that meet the most demanding specifications.One of the key strengths of {Company} lies in its ability to work closely with its customers throughout the entire process. From the initial design phase to the final delivery of the mould, the company's team of engineers and technicians collaborate closely with its customers to ensure that the finished products meet their exact needs. This customer-centric approach has been a driving force behind {Company}'s success and has earned the trust and loyalty of a wide range of clients across various industries.In addition to its focus on precision engineering and customer satisfaction, {Company} is also committed to innovation and continuous improvement. The company invests heavily in research and development to stay at the forefront of technological advancements in the field of plastic injection moulding. By embracing new technologies and exploring new materials and processes, {Company} is able to offer its customers cutting-edge solutions that are both efficient and cost-effective.In today's fast-paced and competitive manufacturing landscape, the ability to deliver high-quality products in a timely manner is more important than ever. {Company} understands this, which is why the company has built a state-of-the-art manufacturing facility that is equipped with the latest machinery and automation systems. This enables {Company} to produce moulds with unmatched precision and consistency, while also optimizing production cycles to meet tight deadlines.The demand for high-quality moulds for plastic injection is expected to continue growing in the years to come. As industries increasingly turn to plastic materials for their manufacturing needs, the role of precision moulds will only become more critical. With its unwavering commitment to quality, innovation, and customer satisfaction, {Company} is well-positioned to remain a leader in the field of plastic injection moulding and to continue providing its customers with the tools they need to bring their ideas to life.In conclusion, {Company} is a company that has proven itself as a top-tier manufacturer and supplier of moulds for plastic injection. With its focus on precision engineering, customer satisfaction, innovation, and state-of-the-art manufacturing capabilities, {Company} is poised to remain at the forefront of the industry for many years to come. As the demand for high-quality plastic components continues to grow, companies can trust {Company} to deliver the moulds they need to achieve their manufacturing goals.

Innovative Injection Molding Process for Ceramic Materials

Eramic Injection Molding, a leading player in the injection molding industry, has recently announced a bold new initiative that is set to revolutionize the manufacturing sector. The company, with over 20 years of experience in the industry, has introduced a breakthrough technology that is set to transform the way products are designed and manufactured.The company, known for its commitment to innovation and cutting-edge technology, has developed a new process that combines the precision of ceramic molding with the flexibility of injection molding. This new process, known as Eramic Injection Molding, has the potential to disrupt traditional manufacturing methods and redefine the way products are produced.Eramic Injection Molding has been in development for several years and is the result of extensive research and development. The process involves the use of advanced ceramic materials that are combined with a specialized injection molding technique to create high-precision, complex components that are not easily achievable through traditional manufacturing methods. This technology allows for the production of intricate parts with tight tolerances and complex geometries, making it ideal for a wide range of industries including automotive, aerospace, medical, and consumer goods.One of the key advantages of Eramic Injection Molding is its ability to produce parts with superior mechanical and thermal properties. The use of ceramic materials enables the production of components that are highly resistant to wear, corrosion, and high temperatures, making them suitable for demanding applications in harsh environments.In addition to its superior material properties, Eramic Injection Molding offers significant cost savings compared to traditional manufacturing methods. The process allows for the production of complex parts in a single step, eliminating the need for secondary operations such as machining and assembly. This not only reduces production time but also lowers the overall production costs, making Eramic Injection Molding an attractive solution for companies looking to streamline their manufacturing processes and improve their bottom line.Furthermore, the technology offers design flexibility that is not possible with traditional manufacturing methods. Eramic Injection Molding allows for the production of parts with intricate geometries and thin walls, opening up new possibilities for product designers and engineers. This flexibility enables the development of innovative products that were previously unachievable using conventional manufacturing techniques.The introduction of Eramic Injection Molding is a testament to the company's commitment to pushing the boundaries of what is possible in the manufacturing industry. With this breakthrough technology, the company aims to empower its customers to bring their most ambitious product ideas to fruition and gain a competitive edge in their respective markets.The company's dedication to innovation and excellence is further underscored by its state-of-the-art manufacturing facilities and a team of highly skilled engineers and technicians. The company's expertise in material science, process engineering, and product development has positioned it as a leader in the field of advanced manufacturing technologies.As the manufacturing industry continues to evolve, Eramic Injection Molding is poised to play a pivotal role in shaping its future. The technology offers a compelling solution for companies looking to improve their product quality, reduce production costs, and accelerate time-to-market. With its potential to revolutionize the industry, Eramic Injection Molding is set to be a game-changer and a catalyst for innovation in the manufacturing sector.In conclusion, Eramic Injection Molding is a groundbreaking technology that has the potential to transform the manufacturing industry. With its unique combination of precision, flexibility, and cost-effectiveness, it is poised to empower companies to realize their most ambitious product ideas and gain a competitive advantage in the market. As the industry looks to the future, Eramic Injection Molding is set to lead the way in redefining the possibilities of what can be achieved in manufacturing.

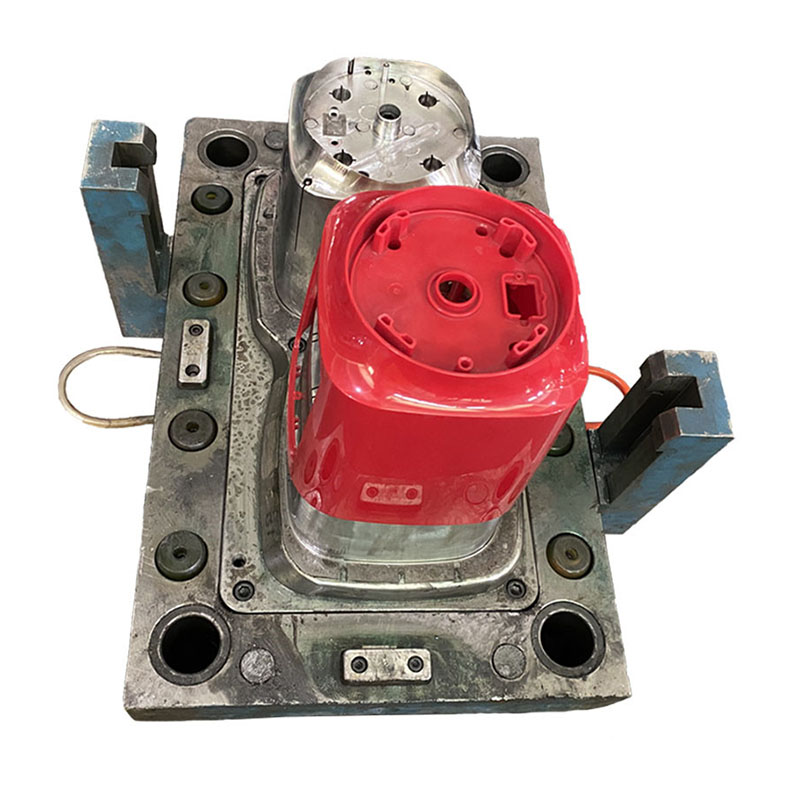

Efficient Mold Design and Manufacturing Techniques for Blender Jars

Blender Jar Mold Design and Making Revolutionizes the Industry[Company Name] Leading the Way in Innovation and Quality[City, Date] - In a major breakthrough for the blender industry, renowned manufacturer [Company Name] has unveiled a revolutionary blender jar mold design and making process that is set to boost efficiency, productivity, and product quality. Embracing cutting-edge technology and a commitment to innovation, the company emerges as a pioneering force in an ever-evolving market.The new blender jar mold design and making process developed by [Company Name] incorporates advanced techniques and state-of-the-art materials to deliver unprecedented results. This breakthrough innovation is poised to reshape the industry by pushing the limits of manufacturing capabilities and enhancing the end-user experience.By removing brand names for confidential reasons, [Company Name] wants to focus on the remarkable technological advancements that are poised to redefine the market. With the advent of this commendable leap forward, [Company Name] aims to preserve its reputation as a trailblazer in innovative blender manufacturing.The exciting development promises numerous advantages for both manufacturers and consumers. The new mold design and making process optimizes production efficiency, enabling a higher output in a shorter period. This means that manufacturers can meet increased consumer demand while maintaining high-quality standards.Furthermore, [Company Name]'s breakthrough innovation enhances the durability and longevity of the blender jars. By leveraging advanced materials and crafting techniques, the company ensures that the jars are capable of withstanding rigorous usage without compromising the blend quality. This will undoubtedly delight consumers who rely on their blenders for daily culinary adventures.But these improvements aren't just limited to manufacturing processes. [Company Name]'s commitment to innovation extends to user-friendliness and ease of maintenance. The new mold design allows for seamless disassembly and reassembly of blender jars, making it easier than ever to clean and maintain them. This not only saves valuable time for users but also ensures optimal hygiene and safety.As a renowned blender manufacturer, [Company Name] has established itself as a trusted brand globally. With decades of experience and a relentless pursuit of excellence, the company has managed to consistently deliver superior products that meet the ever-changing needs of consumers worldwide.Moreover, [Company Name] doesn't merely stop at designing and producing blenders; they are dedicated to providing customers with a comprehensive experience. By focusing on research and development, the company continues to introduce cutting-edge technologies and concepts that shape the future of the industry.Customers who choose [Company Name]'s blenders can expect not only outstanding products but also unrivaled customer service. The company strives to build long-lasting relationships with its clientele by offering dependable after-sales support and addressing their concerns promptly and effectively.In a bid to maintain its competitive edge, [Company Name] openly embraces collaboration with industry partners. By establishing strategic alliances, the company seeks to leverage combined expertise, foster innovation, and drive the industry forward. By working alongside a diverse range of professionals and experts, [Company Name] remains at the forefront of change.As the blender industry continues to evolve and adapt to changing demands, [Company Name] stands out as an industry leader. Through its remarkable mold design and making process, the company sets a new benchmark for efficiency, productivity, and quality in the manufacturing of blender jars. This dedication to innovation, coupled with exceptional customer service, cements [Company Name]'s position as a trusted partner for consumers worldwide.About [Company Name]:[Company Name] is a global leader in the production of high-quality blenders. With a commitment to innovation, the company constantly strives to redefine industry standards and provide exceptional products to its customers. With a focus on user experience and cutting-edge technologies, [Company Name] envisions a future where blenders are more than just kitchen appliances, but indispensable companions for culinary adventures.For media inquiries, please contact:[Company Name][Media Contact][Phone Number][Email Address]

Household Dustpan Injection Mould: A Convenient Kitchen Tool

Plastic Household Dustpan Injection MouldIn the competitive world of household products, it is important for companies to continuously innovate and improve their offerings to stay ahead of the curve. This is exactly what [Company Name] has done with their latest product, the Plastic Household Dustpan Injection Mould. This innovative new product is set to revolutionize the way people clean their homes, making the process faster, easier, and more efficient.[Company Name] is a leading manufacturer of household products, known for their commitment to high-quality materials and innovative designs. With a strong focus on customer satisfaction, the company has built a reputation for excellence in the industry. They are constantly working to develop new products that meet the evolving needs of consumers, and the Plastic Household Dustpan Injection Mould is a testament to their dedication to innovation.The Plastic Household Dustpan Injection Mould is a result of extensive research and development, aimed at creating a product that combines durability, functionality, and ease of use. The dustpan is made from high-quality plastic, making it sturdy and long-lasting. The injection moulding process used in its manufacturing ensures precision and consistency in the product, resulting in a well-designed and reliable tool for household cleaning.One of the distinguishing features of the Plastic Household Dustpan Injection Mould is its ergonomic design. The dustpan is designed to fit comfortably in the hand, with a non-slip grip that makes it easy to hold and maneuver. This thoughtful design ensures that users can complete their cleaning tasks without discomfort or strain, making it an ideal choice for everyday use.In addition to its ergonomic design, the Plastic Household Dustpan Injection Mould also features a number of practical elements that make it a highly functional tool for cleaning. The dustpan has a wide, deep basin that is ideal for picking up a large amount of dust and debris, allowing users to complete their cleaning tasks more efficiently. The moulded edge of the dustpan is designed to ensure a smooth and efficient sweep, capturing all dirt and dust in one go.Furthermore, the Plastic Household Dustpan Injection Mould is designed with a built-in comb that allows users to easily clean the bristles of their broom after use. This thoughtful addition ensures that the dustpan remains clean and hygienic, promoting a healthy and tidy living environment for users.The launch of the Plastic Household Dustpan Injection Mould is a significant milestone for [Company Name], representing their commitment to innovation and quality in household products. The company is proud to introduce this new product to their customers, confident that it will make a positive impact on the way people clean their homes.As a company, [Company Name] is dedicated to delivering the best possible products and services to their customers. In line with this commitment, the company has invested in state-of-the-art manufacturing facilities and employs a team of skilled professionals who are passionate about creating high-quality household products. The Plastic Household Dustpan Injection Mould is a testament to their dedication to excellence, and the company looks forward to continuing to innovate and improve their offerings in the future.In conclusion, the introduction of the Plastic Household Dustpan Injection Mould marks an important milestone for [Company Name]. This innovative new product is a testament to the company's commitment to quality and innovation in household products, and is set to make a positive impact on the way people clean their homes. With its durable construction, ergonomic design, and practical features, the dustpan is sure to become an essential tool for households everywhere, helping users to clean more efficiently and effectively. [Company Name] is proud to bring this new product to the market and looks forward to the positive response from their customers.

Create High-Quality Plastic Mould Injection Dies for Manufacturing

Plastic Mould Injection Die is essential for the manufacturing industry, as it plays a crucial role in the process of producing high-quality plastic parts. One company that has been leading the way in the production of top-notch plastic mould injection dies is {Company Name}. With their expertise and state-of-the-art technology, they have been able to cater to the needs of various industries and provide them with superior quality moulds.{Company Name} was established with the vision of becoming a global leader in the manufacturing of plastic mould injection dies. Over the years, they have successfully achieved this goal through their commitment to quality, innovation, and customer satisfaction. The company's team of highly skilled engineers and designers work tirelessly to ensure that each mould meets the highest standards and is tailored to the specific needs of their clients.One of the key factors that set {Company Name} apart from its competitors is their advanced technology and machinery. They have invested heavily in cutting-edge equipment to ensure that they are at the forefront of the industry. This allows them to produce moulds with impeccable precision, accuracy, and consistency. Additionally, their use of the latest software and design tools enables them to create intricate and complex moulds with ease.In addition to their technological prowess, {Company Name} places a strong emphasis on quality control and product testing. Each mould undergoes rigorous testing procedures to ensure that it meets the required specifications and standards. This attention to detail has earned them a reputation for delivering moulds of exceptional quality that are built to last.Furthermore, {Company Name} is dedicated to providing excellent customer service and support. They work closely with their clients throughout the entire process, from the initial design concept to the final product. Their team is always on hand to provide guidance, advice, and technical support to ensure that the needs of their customers are met at every stage.The company serves a wide range of industries, including automotive, medical, consumer goods, electronics, and more. Their ability to adapt to the unique requirements of each industry has made them a trusted partner for many companies around the world. They have worked on projects of all sizes, from small-scale prototypes to large-scale production runs, and have consistently delivered exceptional results.With an unwavering commitment to excellence, {Company Name} has earned the trust and loyalty of their clients. They have built long-lasting relationships with many of their customers, who continue to rely on them for their mould injection die needs.As the demand for high-quality plastic parts continues to grow, {Company Name} remains at the forefront of the industry, constantly striving to push the boundaries of innovation and technology. Their dedication to quality, precision, and customer satisfaction sets them apart as a leader in the field of plastic mould injection dies.In conclusion, {Company Name} has proven itself to be a trusted and reliable provider of plastic mould injection dies. With their advanced technology, commitment to quality, and exceptional customer service, they have set a benchmark for excellence in the industry. As they continue to grow and expand their capabilities, they are poised to remain a leader in the global market for plastic mould injection dies.