High-Quality Large Plastic Injection Mold for Manufacturing

By:Admin

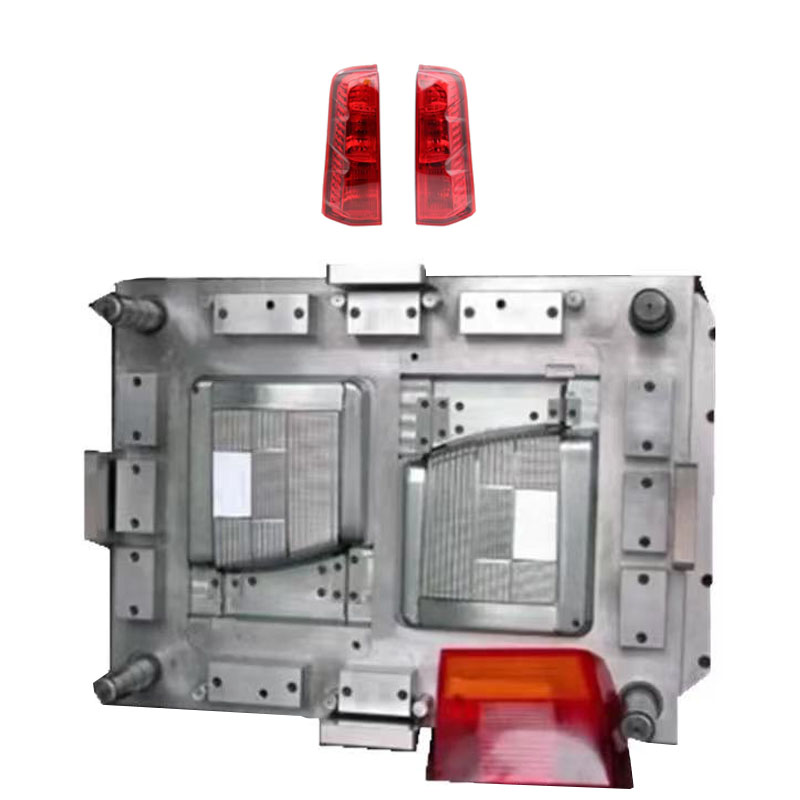

The renowned plastic injection mold manufacturer, (Company Name), has recently unveiled its latest innovation – a large plastic injection mold that is set to revolutionize the industry. The new mold is designed to meet the growing demand for larger and more complex plastic components, and is expected to provide unprecedented opportunities for manufacturers in a wide range of industries.

With over (number of years) of experience in the plastic injection mold industry, (Company Name) has established itself as a leader in innovation and quality. The company's commitment to research and development has resulted in the creation of some of the most advanced and reliable injection molds in the market. The unveiling of the new large plastic injection mold is a testament to the company's dedication to pushing the boundaries of what is possible in the industry.

The new mold is capable of producing plastic components that are significantly larger and more complex than those produced by traditional injection molds. This opens up a world of possibilities for manufacturers, allowing them to create products that were previously thought to be impossible to manufacture using injection molding. The mold is also designed to provide improved precision and efficiency, resulting in higher quality products and reduced manufacturing costs.

One of the key features of the new mold is its modular design, which allows for easy customization and adaptation to specific manufacturing requirements. This means that manufacturers can tailor the mold to their exact needs, ensuring that they are able to produce the highest quality products with maximum efficiency. The mold is also equipped with the latest technology and advanced control systems, further enhancing its capabilities and reliability.

In addition to its technical features, the new large plastic injection mold is also designed with sustainability in mind. (Company Name) has integrated eco-friendly materials and processes into the production of the mold, ensuring that it meets the highest environmental standards. This commitment to sustainability reflects the company's overall ethos of responsible and ethical manufacturing practices.

The unveiling of the new large plastic injection mold has already generated significant interest within the industry. Manufacturers are eager to explore the possibilities that the mold presents, and many are already in discussions with (Company Name) about potential collaborations and partnerships. The mold is expected to have a profound impact on the industry, and (Company Name) is poised to lead the way in its adoption and implementation.

As the demand for larger and more complex plastic components continues to grow, the introduction of the new large plastic injection mold from (Company Name) represents a major step forward for the industry. With its cutting-edge technology, customizable design, and sustainable approach, the mold is set to redefine the possibilities of plastic injection molding and open up new opportunities for manufacturers around the world. (Company Name) continues to demonstrate its commitment to innovation and excellence, and the unveiling of this new mold is a clear testament to its leadership in the industry.

Company News & Blog

Innovative Injection Molding Process for Ceramic Materials

Eramic Injection Molding, a leading player in the injection molding industry, has recently announced a bold new initiative that is set to revolutionize the manufacturing sector. The company, with over 20 years of experience in the industry, has introduced a breakthrough technology that is set to transform the way products are designed and manufactured.The company, known for its commitment to innovation and cutting-edge technology, has developed a new process that combines the precision of ceramic molding with the flexibility of injection molding. This new process, known as Eramic Injection Molding, has the potential to disrupt traditional manufacturing methods and redefine the way products are produced.Eramic Injection Molding has been in development for several years and is the result of extensive research and development. The process involves the use of advanced ceramic materials that are combined with a specialized injection molding technique to create high-precision, complex components that are not easily achievable through traditional manufacturing methods. This technology allows for the production of intricate parts with tight tolerances and complex geometries, making it ideal for a wide range of industries including automotive, aerospace, medical, and consumer goods.One of the key advantages of Eramic Injection Molding is its ability to produce parts with superior mechanical and thermal properties. The use of ceramic materials enables the production of components that are highly resistant to wear, corrosion, and high temperatures, making them suitable for demanding applications in harsh environments.In addition to its superior material properties, Eramic Injection Molding offers significant cost savings compared to traditional manufacturing methods. The process allows for the production of complex parts in a single step, eliminating the need for secondary operations such as machining and assembly. This not only reduces production time but also lowers the overall production costs, making Eramic Injection Molding an attractive solution for companies looking to streamline their manufacturing processes and improve their bottom line.Furthermore, the technology offers design flexibility that is not possible with traditional manufacturing methods. Eramic Injection Molding allows for the production of parts with intricate geometries and thin walls, opening up new possibilities for product designers and engineers. This flexibility enables the development of innovative products that were previously unachievable using conventional manufacturing techniques.The introduction of Eramic Injection Molding is a testament to the company's commitment to pushing the boundaries of what is possible in the manufacturing industry. With this breakthrough technology, the company aims to empower its customers to bring their most ambitious product ideas to fruition and gain a competitive edge in their respective markets.The company's dedication to innovation and excellence is further underscored by its state-of-the-art manufacturing facilities and a team of highly skilled engineers and technicians. The company's expertise in material science, process engineering, and product development has positioned it as a leader in the field of advanced manufacturing technologies.As the manufacturing industry continues to evolve, Eramic Injection Molding is poised to play a pivotal role in shaping its future. The technology offers a compelling solution for companies looking to improve their product quality, reduce production costs, and accelerate time-to-market. With its potential to revolutionize the industry, Eramic Injection Molding is set to be a game-changer and a catalyst for innovation in the manufacturing sector.In conclusion, Eramic Injection Molding is a groundbreaking technology that has the potential to transform the manufacturing industry. With its unique combination of precision, flexibility, and cost-effectiveness, it is poised to empower companies to realize their most ambitious product ideas and gain a competitive advantage in the market. As the industry looks to the future, Eramic Injection Molding is set to lead the way in redefining the possibilities of what can be achieved in manufacturing.

High-Quality Plastic Injection Molds for Sale: Find the Best Deals Now

The demand for high-quality plastic injection molds has been on the rise, and as a response to this growing demand, {Company Name}, a leading manufacturer in the plastic injection molding industry, has announced that they have a wide range of injection molds for sale.{Company Name} has been in the plastic injection molding business for over 20 years, and their expertise and experience in producing high-precision molds have made them a trusted name in the industry. They are known for their commitment to quality and innovation, and their injection molds are used in a wide range of industries, including automotive, medical, consumer goods, and electronics.The company's state-of-the-art manufacturing facility is equipped with the latest technology and machinery, allowing them to produce molds with incredibly tight tolerances and complex geometries. Their team of highly skilled engineers and technicians work tirelessly to ensure that each mold meets the highest standards of quality and performance.{Company Name}'s injection molds are also known for their durability and longevity, thanks to the use of high-quality materials and advanced manufacturing processes. This means that their molds are capable of producing thousands, or even millions, of high-quality plastic parts with minimal maintenance and downtime, making them an excellent investment for businesses looking to streamline their production processes.In addition to their standard injection molds, {Company Name} also offers custom mold design and manufacturing services, allowing their customers to create molds that are tailored to their specific needs and requirements. Whether it's a unique part design, a specialized material, or a specific production volume, the company's team can work closely with their clients to develop a custom mold solution that meets their exact specifications.{Company Name} takes great pride in their commitment to sustainability, and their injection molds are designed with environmental responsibility in mind. Their manufacturing processes are optimized to minimize waste and energy consumption, and they are constantly exploring new ways to reduce their environmental impact. This means that businesses can not only benefit from high-quality molds but also contribute to a more sustainable and eco-friendly manufacturing process.With the announcement of their injection molds for sale, {Company Name} is hoping to cater to the growing demand for high-quality molds in the market. Their extensive catalog of molds covers a wide range of applications and industries, and their custom mold services provide businesses with the flexibility to create molds that suit their unique needs.As the plastic injection molding industry continues to evolve, {Company Name} remains at the forefront of innovation and excellence. Their commitment to quality, precision, and sustainability sets them apart from other manufacturers, and their injection molds are a testament to their dedication to providing the best solutions for their customers.For businesses looking to invest in high-quality plastic injection molds, {Company Name} is a trusted partner that offers reliability, performance, and value. With their extensive experience and expertise, they have the capability to meet the most demanding mold requirements and exceed their customers' expectations.In conclusion, {Company Name}'s announcement of their plastic injection molds for sale is a testament to their ongoing commitment to excellence and innovation. Their injection molds are a result of years of expertise and dedication to quality, and they are poised to meet the growing demand for high-quality molds in the market. Businesses looking for reliable and high-performance injection molds need look no further than {Company Name}, a trusted leader in the industry.

Plastic Injection Mold for Toy Cars: A Detailed Guide

New Toy Car Mold Plastic Injection Technology Revolutionizes the IndustryIn a groundbreaking development, a leading plastic injection company has introduced a new Toy Car Mold Plastic Injection technology that is set to revolutionize the industry. The company, known for its commitment to excellence and innovation, has developed this cutting-edge technology to meet the increasing demand for high-quality toy car molds in the market.The new Toy Car Mold Plastic Injection technology is designed to provide better design flexibility, faster production times, and improved precision in the manufacturing process. With this technology, the company aims to set new standards in the production of toy car molds, offering customers superior quality products that meet their specific requirements.The advanced injection molding technology enables the company to create intricate and detailed toy car molds with impeccable precision. By utilizing state-of-the-art machinery and the latest manufacturing techniques, the company is able to produce molds that are not only visually stunning but also highly functional. This level of precision and attention to detail is made possible by the company's team of experienced engineers and designers, who are dedicated to pushing the boundaries of what is possible in the industry.In addition to the design flexibility and precision offered by the new technology, the company has also significantly reduced the production time for toy car molds. The streamlined manufacturing process allows for quicker turnaround times, ensuring that customers can receive their orders in a timely manner without compromising on quality. This enhanced efficiency has been achieved through the optimization of production workflows, as well as the integration of advanced automation systems into the manufacturing process.It is clear that the new Toy Car Mold Plastic Injection technology is a game-changer for the industry, offering unparalleled benefits to customers and setting new benchmarks for quality and efficiency. As a result, the company has already seen a surge in demand for its products, with clients expressing a keen interest in taking advantage of the advanced capabilities offered by this cutting-edge technology.The company's commitment to excellence extends beyond the products it offers, as it also prioritizes sustainability and environmental responsibility in its manufacturing processes. The new injection molding technology has been developed with a focus on reducing waste and minimizing the environmental impact of production, aligning with the company's environmentally conscious ethos. By implementing sustainable practices in its operations, the company seeks to set an example for the industry and contribute to a greener, more sustainable future.In line with its dedication to innovation, the company is continually investing in research and development to further enhance its capabilities and stay ahead of the curve. By staying at the forefront of technological advancements, the company is able to offer its customers the most advanced and reliable solutions, solidifying its position as a leader in the industry.The introduction of the new Toy Car Mold Plastic Injection technology marks a significant milestone for the company, further establishing its reputation as a trailblazer in the field of plastic injection molding. As the industry continues to evolve, the company remains committed to pushing boundaries and delivering superior products that exceed customer expectations.With its unwavering commitment to excellence, innovation, and sustainability, the company's new Toy Car Mold Plastic Injection technology sets a new standard for the industry, promising to shape the future of plastic injection molding and deliver unmatched value to its customers.

Durable Plastic Products and Injection Moulding Services in China

China Plastic Products and Plastic Injection Mould Industry Continues to ThriveChina has long been known as a global leader in the production of plastic products and plastic injection moulds. With its advanced technology and skilled workforce, the country has solidified its position as a key player in the industry, continuing to thrive despite global challenges.One company that has been at the forefront of this success is {}. Established in {}, the company has garnered a reputation for excellence in the design and manufacturing of plastic products and plastic injection moulds. With a strong focus on innovation and quality, the company has been able to meet the evolving needs of its clients both domestically and internationally.In recent years, the demand for plastic products and plastic injection moulds has continued to rise, driven by various industries such as automotive, electronics, packaging, and consumer goods. China's ability to adapt and scale its production capabilities has allowed companies like {} to capitalize on this growing demand.One of the key factors contributing to the success of the company is its cutting-edge technology and state-of-the-art manufacturing facilities. This has enabled the company to produce high-quality plastic products and injection moulds with precision and efficiency. Additionally, {} has established a strong research and development team, continuously innovating and improving its products to stay ahead of the competition.Furthermore, the company has a strong commitment to sustainability and environmental responsibility. With an increasing focus on eco-friendly materials and production processes, {} has been able to align itself with the global push for a greener and more sustainable future. By offering products that are recyclable and environmentally friendly, the company has been able to attract clients who prioritize sustainability in their supply chain.In addition to its commitment to innovation and sustainability, {} has also placed a strong emphasis on customer satisfaction. By providing tailored solutions and excellent customer service, the company has been able to build long-lasting relationships with its clients. This has further solidified its position as a trusted partner in the industry.As China continues to drive the global market for plastic products and plastic injection moulds, companies like {} are well-positioned to capitalize on the opportunities that lie ahead. With a strong foundation built on innovation, quality, and customer satisfaction, the company is poised for continued success in the years to come.In conclusion, the plastic products and plastic injection mould industry in China continues to thrive, driven by advancements in technology, increasing demand, and a focus on sustainability. Companies like {} have played a pivotal role in this success, with their commitment to excellence and customer satisfaction. As the industry evolves, it is clear that China will remain a dominant force in the production of plastic products and injection moulds on the global stage.

Quality Mold Injection Lens Mould Maker For Plastic Products

Mold Injection Lens Mould Maker, a leading manufacturer of plastic lenses, has been making waves in the optical industry for its high-quality products and innovative manufacturing processes. With a track record of delivering top-notch, custom-made lenses to its clients, Mold Injection Lens Mould Maker has become a trusted partner for opticians, optical stores, and eyewear brands around the world.Established in [year], Mold Injection Lens Mould Maker has been at the forefront of plastic lens manufacturing, leveraging cutting-edge technology and state-of-the-art machinery to produce lenses that meet the highest industry standards. The company's commitment to quality, precision, and customer satisfaction has earned it a reputation as a reliable and preferred supplier in the global optical market.Mold Injection Lens Mould Maker's success can be attributed to its dedication to innovation and continuous improvement. The company invests heavily in research and development to stay ahead of the curve, constantly looking for ways to enhance its manufacturing processes and introduce new, advanced materials. This proactive approach has enabled Mold Injection Lens Mould Maker to offer a diverse range of lenses, catering to various optical needs and requirements.One of the key differentiators for Mold Injection Lens Mould Maker is its in-house design and engineering capabilities. The company's team of skilled and experienced engineers work closely with clients to develop bespoke lens solutions that are tailored to specific applications. From single-vision lenses to progressive lenses, Mold Injection Lens Mould Maker has the expertise and resources to deliver custom-made products that exceed expectations.In addition to its design and engineering strengths, Mold Injection Lens Mould Maker takes pride in its manufacturing prowess. The company operates a modern production facility equipped with advanced injection molding machines and precision tooling, enabling it to produce lenses with exceptional clarity, accuracy, and consistency. Furthermore, Mold Injection Lens Mould Maker is committed to sustainability and environmental responsibility, using eco-friendly materials and minimizing waste in its manufacturing processes.As a testament to its dedication to quality and excellence, Mold Injection Lens Mould Maker holds various certifications and accreditations, ensuring that its products adhere to stringent industry regulations and standards. This commitment to quality assurance has earned the company the trust and loyalty of its diverse clientele, who rely on Mold Injection Lens Mould Maker for their lens manufacturing needs.Looking towards the future, Mold Injection Lens Mould Maker is poised to further expand its reach and capabilities, aiming to strengthen its position as a market leader in plastic lens manufacturing. The company is committed to continuous innovation, investing in the latest technologies and talent to drive its growth and maintain its competitive edge in the optical industry.In conclusion, Mold Injection Lens Mould Maker stands out as a reputable and dependable partner for quality plastic lenses. Its unwavering commitment to precision, innovation, and customer satisfaction has made it a preferred choice for optical businesses worldwide. With a strong emphasis on design, engineering, and manufacturing excellence, Mold Injection Lens Mould Maker is well-positioned to continue delivering exceptional plastic lenses and driving advancements in the optical industry.

Quality Used Plastic Injection Molds for Sale - Chair Moulds Available

Plastic injection molding is a highly sought-after process in the manufacturing industry, and for good reason. With its ability to produce high volumes of identical plastic parts, it has become a cost-effective and efficient method for producing a wide range of products. One company that has capitalized on this technology is [company name], a leading manufacturer of plastic injection molds.[Company name] has recently announced that they are offering a range of used plastic injection molds for chairs. These molds have been thoroughly inspected and refurbished to ensure that they meet the company's high standards for quality and performance. With the growing demand for durable and affordable chairs, [company name] is poised to meet the needs of their customers with these high-quality molds.The used molds for chairs are designed to produce chairs that are not only functional and comfortable but also visually appealing. With the capability to produce chairs in a variety of sizes and styles, these molds offer versatility and flexibility for manufacturers looking to expand their product offerings. Whether it's for a commercial or residential setting, these molds are a valuable asset for companies looking to meet the demand for durable and stylish seating solutions.In addition to offering used plastic injection molds, [company name] also specializes in the design and manufacture of custom molds for a wide range of applications. Their team of highly skilled engineers and technicians work closely with their clients to develop molds that are tailored to their specific needs and requirements. With a focus on precision and innovation, [company name] is able to deliver molds that consistently produce high-quality plastic parts.[Company name] takes great pride in their ability to provide top-notch customer service and support. From the initial consultation to the final delivery of a mold, their team is dedicated to ensuring that their clients' needs are met every step of the way. With a commitment to excellence and a proven track record of success, [company name] has earned a reputation as a trusted partner in the plastic injection molding industry.For companies in search of reliable and cost-effective solutions for plastic injection molds, [company name] is a name to remember. With their extensive selection of used molds and their custom mold design capabilities, they are well-equipped to meet the diverse needs of their clients. Whether it's for chairs or any other plastic part, [company name] is committed to delivering exceptional quality and value.In conclusion, the availability of used plastic injection molds for chairs from [company name] is a testament to their dedication to providing innovative and cost-effective solutions for their clients. With a focus on quality, reliability, and customer satisfaction, they continue to be a leader in the plastic injection molding industry. As the demand for high-quality and durable plastic products continues to grow, [company name] is well-positioned to meet the needs of manufacturers looking for reliable and efficient molding solutions.

High-Quality Injection Mold Parts Factory: Providing Exceptional Products and Services

Injection Mold Parts Factory, a leading manufacturer of high-quality injection mold parts, is making waves in the industry with its innovative products and cutting-edge technology. The company has established a reputation for producing top-notch injection mold parts that meet the highest quality standards, and its commitment to excellence has earned it a loyal customer base.Founded in [year], Injection Mold Parts Factory has quickly become a formidable player in the injection molding industry. The company's state-of-the-art manufacturing facility is equipped with the latest, most advanced machinery and technology, allowing it to produce a wide range of injection mold parts with unparalleled precision and efficiency. From small, intricate components to large, complex parts, Injection Mold Parts Factory has the capabilities to meet the most demanding customer requirements.One of the key factors that sets Injection Mold Parts Factory apart from its competitors is its unwavering dedication to quality. The company adheres to strict quality control measures at every stage of the manufacturing process, ensuring that each part that leaves its facility meets the highest standards of excellence. This commitment to quality has earned Injection Mold Parts Factory the trust and confidence of its customers, who rely on its products for their most critical applications.In addition to its commitment to quality, Injection Mold Parts Factory also places a strong emphasis on innovation. The company invests heavily in research and development to stay at the forefront of technological advancements in the injection molding industry. As a result, Injection Mold Parts Factory is able to offer its customers the latest and most advanced injection mold parts that are tailored to their specific needs and requirements.Furthermore, Injection Mold Parts Factory prides itself on its ability to provide exceptional customer service. The company has a team of highly skilled and experienced professionals who work closely with customers to understand their unique requirements and deliver customized solutions that meet their exact specifications. This customer-centric approach has helped Injection Mold Parts Factory build strong, long-lasting relationships with its clients, who continue to turn to the company for all their injection mold part needs.As Injection Mold Parts Factory continues to grow and expand its presence in the industry, it remains committed to upholding the highest standards of quality, innovation, and customer service. The company is constantly exploring new opportunities for growth and improvement, and it is dedicated to staying ahead of the curve in an ever-evolving market. With its unwavering dedication to excellence, Injection Mold Parts Factory is poised to remain a leader in the injection molding industry for years to come.In conclusion, Injection Mold Parts Factory is a force to be reckoned with in the injection molding industry. With its state-of-the-art manufacturing facility, commitment to quality and innovation, and exceptional customer service, the company has solidified its position as a trusted provider of high-quality injection mold parts. As Injection Mold Parts Factory continues to set new standards for excellence in the industry, it is poised for continued success and growth in the years to come.

Top Plastic Injection Mold Factory: Everything You Need to Know

Plastic Injection Mold Factory, a renowned leader in the plastic molding industry, has been making waves in the market with its innovative technologies and top-notch manufacturing services. With a strong commitment to quality and customer satisfaction, the company has solidified its position as one of the most reliable and trusted mold manufacturers in the industry.The company, which was established in [year], has steadily grown and expanded its operations over the years. With state-of-the-art facilities and a team of highly skilled engineers and technicians, Plastic Injection Mold Factory has the capability to design and produce a wide range of plastic injection molds for various industries, including automotive, medical, consumer goods, and electronics.One of the key factors that sets Plastic Injection Mold Factory apart from its competitors is its unwavering dedication to innovation and continuous improvement. The company constantly invests in the latest technologies and equipment to ensure that it stays ahead of the curve in terms of manufacturing capabilities and product quality. This forward-thinking approach has enabled Plastic Injection Mold Factory to consistently deliver high-quality, precision-engineered molds that meet the exact specifications and requirements of its clients.In addition to its cutting-edge manufacturing capabilities, the company places a strong emphasis on customer service and satisfaction. From the initial design phase to the final delivery of the finished product, Plastic Injection Mold Factory works closely with its clients to ensure that their needs are met and their expectations are exceeded. The company's team of experienced engineers and project managers are committed to providing personalized attention and support throughout the entire mold manufacturing process, from concept to production.Furthermore, Plastic Injection Mold Factory takes its commitment to sustainability and environmental responsibility seriously. The company follows strict guidelines and best practices in its manufacturing processes to minimize waste and reduce its environmental impact. By utilizing advanced, energy-efficient machinery and implementing eco-friendly production methods, Plastic Injection Mold Factory strives to be a responsible corporate citizen and make a positive contribution to the environment.As a result of its unwavering dedication to excellence and customer satisfaction, Plastic Injection Mold Factory has earned a strong reputation in the industry and has garnered a loyal base of clients. The company's track record of delivering high-quality molds on time and within budget has solidified its position as a preferred supplier for many leading companies in various sectors.Looking ahead, Plastic Injection Mold Factory is poised for continued growth and success in the rapidly evolving plastic molding industry. The company is constantly seeking new opportunities to expand its market reach and enhance its capabilities, with a focus on staying at the forefront of technological advancements and industry trends.In conclusion, Plastic Injection Mold Factory stands out as a leading provider of high-quality plastic injection molds, with a strong commitment to innovation, customer satisfaction, and environmental responsibility. With its advanced manufacturing capabilities, dedicated team, and unwavering focus on excellence, the company is well-positioned to continue its success and maintain its status as a trusted industry leader.

Optimize Your Production Process with High-Quality Used Mould for Bottle Plastic Injection Mold

Title: Leading Plastic Manufacturer Introduces Sustainable Solution for Bottle ManufacturingIntroduction:With an aim to revolutionize the plastic bottle manufacturing industry and promote sustainability, a renowned global plastic manufacturing company has recently unveiled its innovative solution - the Used Mould for Plastic Bottle Injection Mold. This breakthrough technology not only enhances manufacturing efficiency but also minimizes environmental impact, marking a significant step towards a greener future.Company Overview:The illustrious plastic manufacturing company, which we are regrettably unable to disclose its name due to confidentiality measures, has been a key player in the industry for several decades. Focused on research and development, the company has consistently strived to introduce cutting-edge solutions that align with sustainable practices.Being at the forefront of the industry, the company has built a strong reputation for its commitment to innovation, quality, and environmental responsibility. By constantly investing in advanced manufacturing techniques and materials, the company has positioned itself as a preferred partner for businesses worldwide looking for sustainable packaging solutions.Used Mould for Plastic Bottle Injection Mold:The company's latest offering, the Used Mould for Plastic Bottle Injection Mold, addresses the pressing issue of plastic waste while ensuring a streamlined manufacturing process. By reusing molds, the company eliminates the need for excessive energy consumption and raw material extraction, which are common drawbacks of traditional manufacturing methods.The injection mold is a crucial component in the plastic bottle production process. By repurposing used molds instead of producing new ones, the company considerably reduces its carbon footprint. Every reused mold translates into lesser energy consumption, reduced waste generation, and ultimately a more sustainable production process.Efficiency and Environmental Benefits:Taking advantage of the company's expertise in engineering and mold design, the Used Mould for Plastic Bottle Injection Mold guarantees optimal efficiency and reduced production costs. The meticulously maintained used molds undergo rigorous inspections and extensive refurbishment to ensure perfect molding execution, resulting in high-quality products.In addition to its economic advantages, the injection mold represents a significant stride towards environmental sustainability. The reduced energy consumption and minimized waste generation contribute to the company's commitment to reducing its ecological impact. By adopting this eco-friendly manufacturing approach, the company sets a pioneering example for others in the industry to follow.Sustainability as a Core Commitment:The introduction of the Used Mould for Plastic Bottle Injection Mold is not an isolated effort, but a part of the company's overarching commitment to sustainability. The company consistently seeks innovative ways to minimize its environmental footprint, be it through responsible sourcing of raw materials or developing recyclable products.Drawing on its extensive experience in the plastic manufacturing industry, the company actively collaborates with researchers, government entities, and other stakeholders to support initiatives that drive sustainability. By sharing its knowledge and resources, the company endeavors to accelerate the adoption of greener practices and foster a circular economy.Conclusion:Through the deployment of the Used Mould for Plastic Bottle Injection Mold, the undisclosed plastic manufacturing company has successfully unveiled an eco-friendly solution that advances the sustainability agenda. By repurposing molds and reducing waste generation, the company has exhibited its commitment to environmental responsibility.As global concerns regarding plastic waste and its impact on the environment intensify, the company's latest innovation offers a glimmer of hope. With its dedication to research and development, coupled with a laser focus on sustainability, the company continues to lead the way towards a greener and more sustainable future for the plastic manufacturing industry.

Key Insights and Advancements in Plastic Injection Molding

[Company Name], a Leading Provider of Plastic Injection Molds, Continues to Pave the Way in Innovative Manufacturing Solutions[City, Date] - Plastic Injection Mold (PIM) production has been an essential aspect of the manufacturing industry for many years. It plays a pivotal role in meeting the demand for high-quality plastic products across various sectors. A company at the forefront of delivering cutting-edge plastic injection molds is [Company Name].With over [number of years] years of industry experience, [Company Name] has established itself as a trusted provider of top-notch plastic injection molds. Their commitment to innovation and customer satisfaction has placed them in a league of their own, consistently delivering exceptional results.Headquartered in [City], [Company Name] boasts a state-of-the-art manufacturing facility equipped with the latest technology and machinery. This allows them to offer an extensive range of plastic injection mold services to cater to the diverse needs of their clients.One of the key factors that sets [Company Name] apart from its competitors is their team of highly skilled and experienced engineers and technicians. These professionals possess a deep understanding of the intricacies of plastic injection molding and are adept at designing molds that optimize both efficiency and quality.By collaborating closely with clients, [Company Name] ensures that the molds they produce align perfectly with the specific requirements of the end product. They leverage cutting-edge software tools and a meticulous design process to craft molds that are not only durable but also capable of producing consistently high-quality products.In addition to their expertise in mold design, [Company Name] also places utmost importance on using high-quality materials. They source materials from trusted suppliers, ensuring that every mold exhibits excellent durability and longevity. By prioritizing the use of superior materials, [Company Name] ensures that their molds can withstand the demanding requirements of high-volume production.One of the standout features of [Company Name] is their commitment to keeping abreast of the latest industry trends and technological advancements. They continually invest in research and development, exploring new materials, processes, and technologies to stay ahead of the curve. This dedication to innovation allows them to offer their clients the most cutting-edge solutions, enhancing productivity and efficiency.[Company Name]'s dedication to customer satisfaction is reflected in their comprehensive after-sales support. They offer ongoing technical assistance and maintenance services to ensure the molds continue to perform optimally throughout their lifecycle. This commitment to building long-term partnerships enables [Company Name] to become a trusted collaborator for manufacturing companies worldwide.As a market leader in plastic injection mold production, [Company Name] has an impressive portfolio of successful projects across diverse industries such as automotive, healthcare, consumer goods, and more. Their molds have played a crucial role in shaping countless products that have become integral parts of our daily lives.With an unwavering commitment to quality, innovation, and customer satisfaction, [Company Name] continues to pave the way in the plastic injection mold industry. By combining their technical expertise, state-of-the-art facility, and keen eye for industry trends, they are pushing the boundaries of what is possible in plastic manufacturing.[Company Name]'s dedication to delivering top-notch plastic injection molds has earned them the trust and confidence of clients worldwide. As they strive to set new industry standards, there is no doubt that [Company Name] will continue to be at the forefront of the global plastic injection mold market.About [Company Name]:[Company Name] is a renowned provider of plastic injection molds, offering a comprehensive range of services to clients across various industries. With a focus on innovation, superior materials, and excellent customer support, [Company Name] has established itself as a trusted partner for manufacturing companies worldwide. For more information, please visit their website at [Company Website].Press Contact:[Name][Title][Phone Number][Email Address]