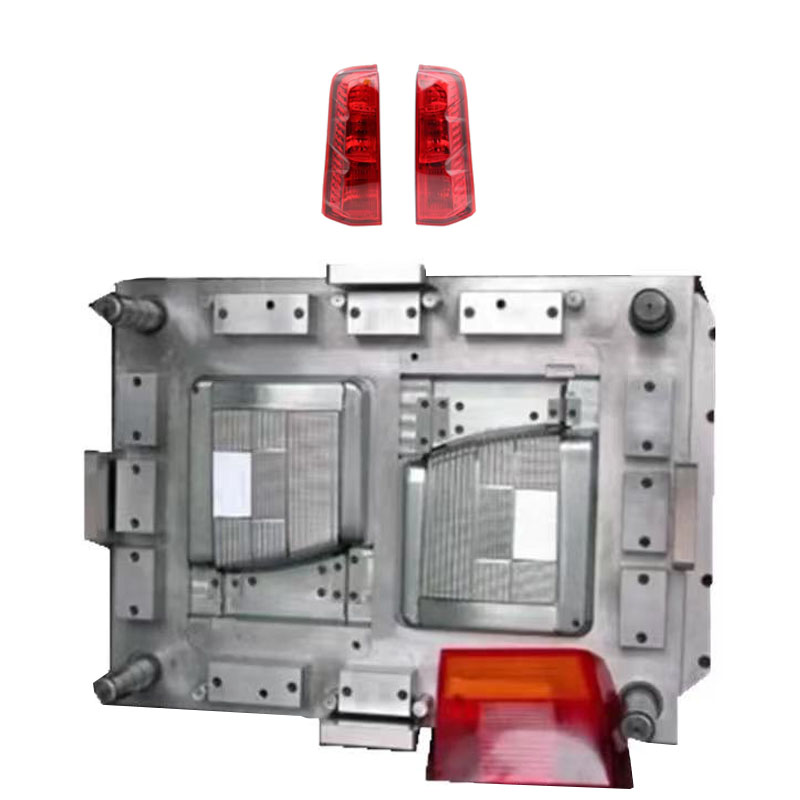

High-Quality Plastic Case Injection Mould Molding Service

By:Admin

With the increasing demand for high-quality and cost-effective plastic injection molding solutions, more and more companies are turning to professional service providers to meet their production needs. One such company that has been making waves in the industry is (remove brand name), offering top-of-the-line plastic case injection mold molding service to a wide range of industries.

The plastic injection molding process is a crucial component of many manufacturing operations, and having a reliable and experienced partner to provide this service is essential for the success of any project. (remove brand name) has positioned itself as a leader in the industry, offering a comprehensive range of plastic case injection molding services to meet the diverse needs of its clients.

The company takes pride in its state-of-the-art facilities and cutting-edge technology, allowing them to deliver precise and high-quality plastic injection molded parts. Whether it's a small batch production or a high-volume order, (remove brand name) has the capabilities to handle projects of any scale, delivering exceptional results every time.

One of the key factors that set (remove brand name) apart from its competitors is its team of highly skilled and experienced professionals. The company's dedicated engineers and technicians work closely with clients to understand their unique requirements and provide tailored solutions that meet their specific needs. This collaborative approach ensures that each project is executed with the utmost precision and attention to detail, resulting in top-quality plastic case injection molded parts.

In addition to its technical expertise, (remove brand name) is also committed to maintaining the highest standards of quality and safety in its operations. The company strictly adheres to industry regulations and best practices, ensuring that all products are manufactured to the highest standards and meet the necessary quality and safety certifications.

Furthermore, (remove brand name) places a strong emphasis on cost-effectiveness and efficiency in its plastic case injection molding service. The company continuously invests in the latest technology and process improvements to streamline its operations and reduce production costs, ultimately offering competitive pricing without compromising on quality.

With a proven track record of delivering superior plastic case injection molding solutions, (remove brand name) has established itself as a trusted partner for a wide range of industries. From electronics and automotive to consumer goods and medical devices, the company's services cater to diverse applications, providing reliable and cost-effective solutions to its clients.

In conclusion, (remove brand name) has positioned itself as a leading provider of plastic case injection mold molding service, offering a comprehensive range of solutions to meet the diverse needs of its clients. With its state-of-the-art facilities, experienced team, commitment to quality and safety, and focus on cost-effectiveness, the company has earned a reputation for delivering top-quality plastic injection molded parts to various industries. As the demand for high-quality plastic injection molding solutions continues to grow, (remove brand name) stands ready to meet the needs of its clients with its unparalleled expertise and capabilities.

Company News & Blog

Ultimate Guide to Aluminum Injection Molding: Everything You Need to Know

Injection Molding Aluminum, a cutting-edge manufacturing process, has been making waves in the industry due to its remarkable efficiency and precision in producing high-quality parts. This innovative technology has been adopted by leading companies such as {}, a renowned manufacturer in the automotive and aerospace sectors.Established in 1995, {} has been at the forefront of delivering advanced engineering solutions to its global clientele. Specializing in the production of components for industries such as automotive, aerospace, defense, and medical, the company has built a solid reputation for its commitment to excellence and continuous innovation.The adoption of Injection Molding Aluminum technology has further solidified {}'s position as a leader in the industry. This state-of-the-art process has enabled the company to offer its customers an advanced manufacturing solution that delivers unparalleled precision, consistency, and cost-effectiveness.Injection Molding Aluminum is a highly efficient manufacturing process that involves injecting molten aluminum into a mold cavity at high pressure. This results in the production of complex and intricate parts with exceptional accuracy and surface finish. The process is ideal for producing lightweight and durable components, making it a perfect fit for industries such as automotive and aerospace where materials with superior strength-to-weight ratios are essential.By leveraging Injection Molding Aluminum, {} has been able to meet the increasing demand for lightweight and high-strength parts in the automotive and aerospace sectors. The technology has enabled the company to manufacture components that not only meet but exceed the stringent performance and quality standards of these industries.One of the key advantages of Injection Molding Aluminum is its ability to produce parts with minimal material waste. This results in a more sustainable and environmentally friendly manufacturing process, aligning with {}'s commitment to responsible and eco-friendly production practices. With a focus on reducing the environmental impact of its operations, the company continues to invest in cutting-edge technologies that promote sustainability and resource efficiency.Furthermore, Injection Molding Aluminum offers a shorter production cycle and reduced lead times, allowing {} to improve its operational efficiency and meet tight project deadlines. This has been particularly advantageous for the company's clients in the automotive and aerospace sectors, where time-to-market is crucial for staying ahead of the competition.In addition to its technological advancements, {} is also dedicated to maintaining the highest quality standards in all aspects of its operations. The company has earned various certifications and accreditations, including ISO 9001 and AS9100, demonstrating its commitment to delivering superior quality products and services to its customers.With Injection Molding Aluminum, {} has expanded its capabilities and enhanced its ability to provide innovative solutions to its diverse range of clients. From intricate components for luxury automobiles to critical parts for aerospace applications, the company has demonstrated its versatility and expertise in meeting the unique requirements of each industry it serves.Looking ahead, {} remains committed to pushing the boundaries of innovation and excellence in manufacturing. The company continues to invest in research and development, seeking out new technologies and processes that will further enhance its capabilities and drive the next generation of manufacturing solutions.As a leading expert in the automotive and aerospace manufacturing sectors, {} is well-positioned to continue its growth and success, delivering exceptional products and services that meet the evolving needs of the industry. With its adoption of Injection Molding Aluminum, the company has once again demonstrated its commitment to staying at the forefront of manufacturing innovation and leading the way in delivering advanced engineering solutions to its global clients.

Custom Mold Injection Services: Find the Right Manufacturer for Your Needs

CNC Mold Injection Maker, a leading manufacturer in the plastic injection molding industry, is making significant advancements in the production of high-quality molds for various applications. With a strong commitment to innovation and customer satisfaction, {Company Name} has established itself as a reliable and trusted partner for companies looking to achieve precise and efficient mold injection solutions.The company's state-of-the-art facility is equipped with cutting-edge CNC machines and advanced mold making technologies, allowing them to produce molds with exceptional accuracy and consistency. This capability has enabled {Company Name} to cater to the diverse needs of industries such as automotive, medical, consumer goods, and electronics, among others.One of the key strengths of {Company Name} is its team of highly skilled and experienced engineers and technicians. They work closely with clients to understand their specific requirements and provide custom mold injection solutions that meet or exceed their expectations. By leveraging their expertise and industry knowledge, {Company Name} is able to deliver molds that are tailored to the unique needs of each customer, ensuring optimal performance and efficiency.In addition to custom mold making, {Company Name} also offers a range of value-added services to support its clients throughout the entire mold injection process. This includes design assistance, prototype development, mold testing and validation, and ongoing technical support. By offering a comprehensive suite of services, {Company Name} aims to streamline the manufacturing process for its customers and help them bring their products to market faster and more cost-effectively.One of the hallmarks of {Company Name} is its unwavering commitment to quality and precision. Through the use of advanced inspection and quality control measures, the company ensures that every mold produced meets the highest standards of excellence. This dedication to quality has earned {Company Name} a stellar reputation in the industry, and the trust of numerous clients who rely on their expertise to produce top-notch molds for their applications.Looking ahead, {Company Name} is poised to continue its growth and success in the mold injection industry. With a focus on continuous improvement and investment in the latest technologies, the company is well-positioned to meet the evolving needs of its clients and exceed their expectations. By staying at the forefront of innovation and excellence, {Company Name} is dedicated to being a strategic partner for companies seeking superior mold injection solutions.In conclusion, {Company Name} is a leading CNC Mold Injection Maker with a proven track record of delivering high-quality, custom molds for a wide range of applications. With a strong emphasis on innovation, precision, and customer satisfaction, the company has earned a reputation as a trusted partner in the industry. As {Company Name} continues to expand its capabilities and offerings, it remains committed to providing exceptional mold injection solutions that empower its clients to succeed in their respective markets.

Top Plastic Injection Molding Mould Manufacturer in China

China Plastic Injection Molding Mould Manufacturer, a leading company in the plastics industry, is making waves in the market with its innovative solutions and high-quality products. With a focus on precision and efficiency, the company has established itself as a trusted partner for businesses across various sectors.Specializing in the design and manufacture of plastic injection molds, the company has a strong track record of delivering customized solutions to meet the unique needs of its clients. From small, intricate components to larger, more complex parts, China Plastic Injection Molding Mould Manufacturer has the expertise and capabilities to handle a wide range of projects with precision and accuracy.One key factor that sets the company apart from its competitors is its commitment to using advanced technology and cutting-edge equipment. By investing in state-of-the-art machinery and tools, China Plastic Injection Molding Mould Manufacturer is able to ensure the highest level of quality and consistency in its products. This, in turn, has earned the company a reputation for excellence and reliability in the industry.In addition to its technical prowess, China Plastic Injection Molding Mould Manufacturer is also recognized for its focus on innovation and continuous improvement. The company's team of skilled engineers and designers are constantly exploring new techniques and methodologies to improve the efficiency and performance of its products. This proactive approach to research and development has enabled the company to stay ahead of the curve and offer its clients cutting-edge solutions that meet their evolving needs.Furthermore, China Plastic Injection Molding Mould Manufacturer places a strong emphasis on customer satisfaction and is dedicated to providing exceptional service at every stage of the process. From initial concept and design to production and delivery, the company works closely with its clients to ensure their requirements are met and their expectations exceeded. This high level of customer care has been a key factor in the company's success and has led to long-standing relationships with many of its clients.With a focus on sustainability and environmental responsibility, China Plastic Injection Molding Mould Manufacturer also prioritizes the use of eco-friendly materials and processes in its operations. By minimizing waste and reducing its carbon footprint, the company is committed to playing its part in creating a more sustainable future for the plastics industry.Looking ahead, China Plastic Injection Molding Mould Manufacturer is well-positioned to continue its growth and success in the market. With a strong foundation of technical expertise, a focus on innovation, and a commitment to customer satisfaction, the company is poised to further expand its reach and solidify its position as a leader in the plastics industry.In conclusion, China Plastic Injection Molding Mould Manufacturer has proven itself to be a reliable and innovative partner for businesses in need of high-quality plastic injection molds. With a dedication to excellence, a focus on customer satisfaction, and a commitment to sustainability, the company is well-equipped to meet the evolving needs of its clients and continue its success in the industry.

High Quality Coffee Maker Production Mould Design and Manufacturing

Express Coffee Maker Production Mould design and makingIn response to the growing demand for high-quality coffee makers, [Company Name] has recently announced its collaboration with a leading mould design and manufacturing company to develop state-of-the-art production moulds for its express coffee makers. This partnership aims to enhance the efficiency and precision of the manufacturing process, ultimately resulting in a superior product for coffee enthusiasts worldwide.The production mould design and making process is a critical component in the manufacturing of express coffee makers. By partnering with an esteemed mould design and manufacturing company, [Company Name] is dedicated to ensuring that its coffee makers are produced with the highest level of craftsmanship and attention to detail. The advanced mould technology will enable the company to achieve consistent quality and performance in its products, meeting the needs and expectations of its discerning customers.With a strong emphasis on innovation and quality, [Company Name] has built a solid reputation in the coffee maker industry. The company prides itself on delivering reliable and stylish products that cater to the evolving preferences of coffee enthusiasts. By incorporating cutting-edge production moulds into its manufacturing process, [Company Name] is further solidifying its commitment to excellence and customer satisfaction.The collaboration with the mould design and manufacturing company reflects [Company Name]'s dedication to staying at the forefront of industry advancements. By investing in advanced production technology, the company is positioning itself as a leader in the market and setting new standards for coffee maker manufacturing. This strategic move will not only elevate the quality of [Company Name]'s products but also enhance its competitive edge in the industry.Furthermore, [Company Name]'s commitment to sustainability and eco-friendliness is also a key consideration in the production mould design and making process. The company is taking proactive steps to ensure that the production of its coffee makers is environmentally responsible, aligning with its values and the expectations of its environmentally conscious customer base. The advanced production moulds will facilitate the efficient use of materials and resources, minimizing waste and reducing the company's environmental footprint.In addition to its dedication to product quality and environmental sustainability, [Company Name] is recognized for its dedication to customer satisfaction. The company has a strong focus on delivering exceptional customer service and support, ensuring that every customer's experience with its products is positive and fulfilling. The integration of advanced production moulds will further reinforce [Company Name]'s ability to consistently meet and exceed customer expectations, solidifying its position as a trusted brand in the coffee maker industry.As [Company Name] progresses with the development of its new production moulds for express coffee makers, the company is poised to elevate the standard of excellence in coffee maker manufacturing. By leveraging the expertise and technology of its partner mould design and manufacturing company, [Company Name] is poised to usher in a new era of precision, efficiency, and quality in its production process. This strategic initiative will not only benefit the company and its customers but will also have a positive impact on the coffee maker industry as a whole.In conclusion, the collaboration between [Company Name] and the mould design and manufacturing company represents a significant milestone in the ongoing advancement of express coffee maker production. With a strong emphasis on quality, innovation, and sustainability, [Company Name] is dedicated to delivering exceptional products and experiences to its customers. The integration of advanced production moulds will further reinforce the company's position as a leader in the industry, setting new benchmarks for excellence in coffee maker manufacturing.

Top 10 Plastic Handle Injection Moulds for High-Quality Results

Plastic Handle Injection Mould Brings Innovation to Manufacturing ProcessesIn today’s fast-paced and competitive manufacturing industry, innovation is key to staying ahead of the curve. One company that has been leading the way in this regard is {Company Name}, a top manufacturer of plastic injection molds.{Company Name} has recently introduced a new plastic handle injection mould that promises to revolutionize the manufacturing process for a wide range of products. This new injection mould is set to bring about significant improvements in efficiency, cost-effectiveness, and quality for manufacturers across various industries.The plastic handle injection mould is designed to produce high-quality plastic handles with precision and speed. This innovative mould is capable of producing handles in a variety of shapes and sizes, making it versatile and adaptable to different manufacturing needs. Moreover, its ergonomic design ensures that the handles produced are comfortable to hold and use.One of the key advantages of the plastic handle injection mould is its ability to streamline the manufacturing process. With this mould, manufacturers can expect reduced cycle times and increased production rates, ultimately leading to improved overall efficiency. Additionally, the mould’s robust construction and advanced design ensure that it delivers consistent and reliable performance, resulting in high-quality finished products.Cost-effectiveness is another significant benefit that the plastic handle injection mould offers. By optimizing the manufacturing process and reducing material waste, this mould helps manufacturers cut down on production costs and improve their bottom line. This makes it an attractive and viable investment for businesses looking to enhance their manufacturing capabilities and remain competitive in the market.Furthermore, the plastic handle injection mould reflects {Company Name}’s commitment to sustainability. By enabling manufacturers to produce high-quality plastic handles with minimal waste and energy consumption, this mould supports environmentally friendly manufacturing practices. This aligns with {Company Name}’s dedication to responsible and sustainable manufacturing, ensuring that businesses can achieve their production goals while minimizing their environmental impact.{Company Name} has built a solid reputation as a leading manufacturer of plastic injection molds, known for its commitment to innovation, quality, and customer satisfaction. With the introduction of the plastic handle injection mould, the company continues to demonstrate its dedication to pushing the boundaries of manufacturing technology and empowering businesses to achieve their production goals efficiently and effectively.Innovation has always been at the core of {Company Name}’s philosophy. The company invests heavily in research and development to constantly improve its products and offer cutting-edge solutions to its customers. The plastic handle injection mould is a testament to {Company Name}’s innovative spirit and its ongoing efforts to meet the evolving needs of the manufacturing industry.As the global manufacturing landscape continues to evolve, the demand for advanced and efficient production solutions is on the rise. The plastic handle injection mould is positioned to meet this growing demand, offering manufacturers a competitive edge in terms of productivity, cost-efficiency, and product quality. With this innovative mould, {Company Name} is empowering businesses to achieve their manufacturing goals and stay ahead in today’s dynamic and competitive market.In conclusion, the plastic handle injection mould from {Company Name} represents a significant advancement in manufacturing technology. With its ability to enhance efficiency, reduce costs, and improve product quality, this innovative mould is set to make a profound impact on the manufacturing industry. As businesses continue to seek innovative and sustainable solutions for their production needs, the plastic handle injection mould stands out as a game-changing solution that promises to drive the industry forward.

High-Quality Injection Plastic Dog House Mould for Sale

Injection Plastic Dog House Mould: A New Addition to the Innovative Product LineIn the world of pet care and accessories, there is a continuous demand for high-quality and innovative products that can enhance the lives of our furry friends. With this in mind, {Company Name} is proud to announce the addition of the Injection Plastic Dog House Mould to its extensive product line. This new offering is set to revolutionize the way pet owners provide shelter for their beloved dogs, combining durability, functionality, and stylish design.{Company Name} has been a leading player in the pet care industry for many years, known for its commitment to providing top-notch products for pets and their owners. With a strong emphasis on innovation and quality, the company has earned a reputation for delivering exceptional solutions for the needs of pets across the globe.The Injection Plastic Dog House Mould is the latest in a long line of innovative products from {Company Name}, and it is set to make a significant impact in the pet care market. This mould has been meticulously designed and crafted to meet the specific needs of dogs, providing a comfortable and secure shelter that can withstand the elements and provide a safe haven for pets.One of the key features of the Injection Plastic Dog House Mould is its durability. Constructed from high-quality, long-lasting plastic, this mould is designed to be weather-resistant and can withstand the wear and tear of outdoor use. This means that pet owners can rest assured that their dogs will have a reliable and safe shelter, no matter the conditions.In addition to its durability, the Injection Plastic Dog House Mould boasts a functional design that takes into account the needs of both pets and their owners. The mould features a spacious and comfortable interior, providing ample room for dogs to relax and rest. The design also incorporates ventilation and insulation, ensuring that dogs are kept comfortable in all weather conditions.Moreover, the mould is easy to assemble and clean, making it a convenient option for pet owners. Its sleek and modern design also adds a touch of style to any outdoor space, making it a welcome addition to any home or pet care facility.{Company Name} is excited to bring this innovative product to the market, and the team is confident that it will be well-received by pet owners and their furry friends. The company's commitment to quality and innovation is evident in every aspect of the Injection Plastic Dog House Mould, and it is set to become a must-have product for pet owners looking to provide the best for their dogs.The Injection Plastic Dog House Mould is a testament to {Company Name}'s dedication to meeting the evolving needs of pets and their owners. With this new addition to its product line, the company continues to set the standard for excellence in the pet care industry, and pet owners can look forward to more innovative solutions in the future.In conclusion, the Injection Plastic Dog House Mould from {Company Name} is a game-changer in the pet care market. With its durable construction, functional design, and stylish appeal, it is sure to become a popular choice for pet owners looking to provide the best for their dogs. As {Company Name} continues to lead the way in the industry, pet owners can expect to see more innovative and high-quality products that enhance the lives of their beloved pets.

Custom Injection Molding and Part Injection Mould in China

China Custom Injection Molding and Part Injection Mould, a major player in the injection molding industry, has been making waves in the global market with its high-quality products and advanced technology. The company, based in China, has built a strong reputation for providing custom injection molding solutions to a wide range of industries including automotive, medical, consumer goods, and electronics.With a commitment to innovation and customer satisfaction, China Custom Injection Molding and Part Injection Mould has been at the forefront of developing cutting-edge injection molding technology. The company’s state-of-the-art manufacturing facilities are equipped with the latest machinery and tools to ensure precision and efficiency in producing high-quality injection molded parts.One of the key factors that sets China Custom Injection Molding and Part Injection Mould apart from its competitors is its dedication to meeting the specific needs of its clients. The company’s team of experienced engineers and designers work closely with customers to understand their unique requirements and provide tailored solutions to meet their exact specifications.In addition to custom injection molding, China Custom Injection Molding and Part Injection Mould also specializes in part injection mold manufacturing. The company’s expertise in mold design and production ensures that customers receive the best possible solutions for their injection molding needs. With a focus on precision engineering and quality control, China Custom Injection Molding and Part Injection Mould consistently delivers top-notch injection molded parts to its global clientele.The company’s commitment to quality is further evident in its adherence to strict manufacturing standards and practices. China Custom Injection Molding and Part Injection Mould is certified to ISO 9001, demonstrating its dedication to maintaining the highest levels of quality and reliability in its products and services.China Custom Injection Molding and Part Injection Mould’s dedication to excellence has earned it a solid reputation in the global market. By continually investing in research and development, the company stays ahead of the curve in terms of technological advancements and industry trends. This forward-thinking approach allows China Custom Injection Molding and Part Injection Mould to remain a trusted partner for clients seeking high-quality injection molding solutions.As the demand for custom injection molding continues to grow, China Custom Injection Molding and Part Injection Mould is well-positioned to capitalize on this trend. The company’s proven track record, commitment to quality, and dedication to customer satisfaction set it apart as a leader in the injection molding industry. With a focus on innovation and excellence, China Custom Injection Molding and Part Injection Mould is poised to continue making significant contributions to the global manufacturing sector.In conclusion, China Custom Injection Molding and Part Injection Mould’s dedication to providing high-quality custom injection molding solutions has solidified its position as a leader in the industry. With a focus on innovation, precision, and customer satisfaction, the company continues to set the standard for excellence in injection molding. As the demand for custom injection molding solutions continues to rise, China Custom Injection Molding and Part Injection Mould is well-prepared to meet the needs of its global clientele and maintain its reputation as a trusted provider of high-quality injection molded parts.

Top Plastic Injection Mould Supplier for Your Manufacturing Needs

Plastic Injection Mould Supplier Announces Expansion and InnovationAs a leading provider of plastic injection moulds, {the company} has been making waves in the industry with its commitment to innovation and customer satisfaction. With a proven track record of delivering high-quality products and exceptional service, {the company} has built a reputation as a trusted partner for businesses looking to improve their manufacturing processes.With the demand for plastic injection moulds on the rise, {the company} has announced plans to expand its operations and invest in new technologies to better serve its customers. The company aims to offer more diverse and advanced solutions to meet the evolving needs of its clients in various industries, including automotive, medical, packaging, and consumer goods.{The company} is known for its state-of-the-art manufacturing facilities and a team of experienced engineers and technicians who are dedicated to delivering precision-engineered moulds. The company's extensive product range includes custom moulds, multi-cavity moulds, and hot runner moulds, among others. By leveraging cutting-edge design and production techniques, {the company} is able to provide cost-effective and efficient solutions to its customers.In addition to its commitment to quality, {the company} places a strong emphasis on sustainability and environmental responsibility. The company has implemented eco-friendly practices in its manufacturing processes, such as recycling and reducing waste, to minimize its impact on the environment. As the industry continues to prioritize sustainability, {the company} is well-positioned to meet the growing demand for eco-conscious solutions.The expansion plans outlined by {the company} include the acquisition of advanced machinery and equipment to enhance its production capabilities. This investment will enable the company to offer a wider range of moulding options, including larger and more complex designs, while maintaining its high standards of quality and precision.Furthermore, {the company} is focusing on research and development to stay at the forefront of technological advancements in the plastic injection moulding industry. By collaborating with industry partners and investing in cutting-edge technologies, the company is committed to staying ahead of the curve and providing its customers with the most innovative solutions available.{The company} has also expressed its dedication to building strong partnerships with its clients, working closely with them to understand their specific requirements and delivering tailored solutions to meet their needs. By fostering open communication and collaboration, {the company} aims to build long-term relationships with its customers based on trust, reliability, and mutual success.In response to the announcement, industry experts have applauded {the company} for its forward-thinking approach and commitment to excellence. With the expansion and innovation plans set in motion, {the company} is poised to strengthen its position as a leading plastic injection mould supplier, offering industry-leading products and services to businesses around the world.In conclusion, {the company} is setting a new standard for plastic injection mould suppliers with its dedication to quality, innovation, and customer satisfaction. With its expansion plans and investment in advanced technologies, the company is well-equipped to meet the evolving needs of its clients and contribute to the advancement of the industry. As {the company} continues to grow and innovate, it remains a reliable partner for businesses seeking top-tier plastic injection mould solutions.

Enhance Your Furniture with Stylish Plastic Injection Mold Decorative Handles

Plastic Injection Mould Decorative Furniture Handle Revolutionizes Interior Design[City, Date] – In the ever-evolving world of interior design, innovation and creativity are crucial. One company leading the way in bringing cutting-edge solutions to the market is [Company Name]. With their latest creation, the Plastic Injection Mould Decorative Furniture Handle, they are revolutionizing how furniture is accessorized and transforming the aesthetics of living spaces.[Company Name] has earned a reputation for pushing the boundaries of design and craftsmanship. Their commitment to quality and attention to detail has made them a leader in the industry. The new Plastic Injection Mould Decorative Furniture Handle is a testament to their dedication to excellence.This groundbreaking handle is not just a functional component of furniture; it is an artistic masterpiece that elevates the overall look of any piece it adorns. Made from high-quality plastic through an advanced injection molding process, the handle is not only durable but also customizable to fit the unique style of each customer.One of the key advantages of the Plastic Injection Mould Decorative Furniture Handle is its wide range of design options. The handle comes in a variety of shapes, sizes, and finishes, enabling customers to select the perfect match for their furniture style. Whether it's a sleek and modern look or a more traditional and ornate design, there is a handle for every taste.Moreover, the injection molding process ensures that each handle is produced with precision and consistency, guaranteeing uniform quality across multiple pieces. This ensures that the handles maintain their form and functionality, no matter how frequently they are used.Not only are these handles visually appealing, but they are also ergonomically designed to provide optimal comfort and ease of use. Their enhanced grip and smooth finish make opening drawers and doors effortless, adding convenience to the overall furniture experience.The Plastic Injection Mould Decorative Furniture Handle is not confined to specific types of furniture. It is versatile and can be seamlessly integrated into various pieces, including cabinets, wardrobes, dressers, and even kitchen cabinets. This versatility expands the possibilities of incorporating these handles into different interior design styles and applications.Furthermore, the environmental impact of these handles is significantly reduced compared to traditional manufacturing methods. The injection molding process minimizes material waste and allows for recycling, making them an eco-friendly choice for conscious customers.[Company Name], with its deep understanding of the market demands, ensures that the Plastic Injection Mould Decorative Furniture Handle is not only of superior quality but also reasonably priced. This accessibility allows a wider range of customers to experience the transformative effects of these handles on their furniture pieces.As the demand for unique and personalized furniture accessories continues to grow, [Company Name] remains at the forefront of providing innovative solutions. With the introduction of the Plastic Injection Mould Decorative Furniture Handle, they have once again proven themselves as pioneers in the industry, setting new standards for design, functionality, and aesthetics.In conclusion, the Plastic Injection Mould Decorative Furniture Handle manufactured by [Company Name] is a game-changer in the world of interior design. Its artistic designs, customizable options, and durability make it the perfect addition to any furniture piece. With this remarkable creation, [Company Name] continues to inspire creativity and redefine the way we perceive furniture handles.

The Advantages of Small Plastic Injection Moulds

Plastic Injection Mould Small is in high demand in many industries due to its ability to produce intricate and precise plastic components. The small size of these molds makes them ideal for producing small plastic parts, which are used in various consumer products, medical devices, automotive components, and electronic devices. This growing demand for small plastic injection molds has led to the development of advanced manufacturing techniques to meet the industry's requirements.The small plastic injection mold market is dominated by several key players who have a long history of providing high-quality products to their customers. These companies have a deep understanding of the intricacies involved in creating small plastic injection molds and have a proven track record of delivering top-notch products. One such company is {}, which has been a leader in the plastic injection molding industry for many years.{} is renowned for its expertise in designing and manufacturing small plastic injection molds. The company has a team of highly skilled engineers and designers who work tirelessly to create innovative and efficient mold designs. With state-of-the-art manufacturing facilities and cutting-edge technology, {} is able to produce small plastic injection molds that meet the exact specifications of its clients. The company has earned a reputation for delivering high-quality molds that are durable, reliable, and cost-effective.The small plastic injection molds produced by {} are used in a wide range of industries, including automotive, electronics, medical, and consumer goods. These molds are capable of producing complex geometries, tight tolerances, and intricate details, making them ideal for manufacturing small plastic parts. {} takes pride in its ability to provide customized mold solutions to meet the specific needs of its diverse clientele. The company works closely with its customers to understand their requirements and deliver molds that exceed their expectations.One of the key factors that set {} apart from its competitors is its commitment to continuous improvement and innovation. The company invests heavily in research and development to stay ahead of the curve and incorporate the latest advancements in mold design and manufacturing. This dedication to innovation has enabled {} to develop cutting-edge small plastic injection molds that deliver exceptional performance and reliability.In addition to its technical expertise, {} is also known for its outstanding customer service. The company has a team of dedicated professionals who are committed to providing exceptional support to its clients throughout the mold design and manufacturing process. {} understands the importance of fostering strong relationships with its customers and works tirelessly to ensure that their needs are met with the highest level of professionalism and care.As the demand for small plastic injection molds continues to grow, {} remains at the forefront of the industry, providing innovative solutions to its clients. The company's relentless pursuit of excellence and dedication to customer satisfaction have solidified its position as a trusted partner for small plastic injection mold needs.In conclusion, plastic injection molding is an essential manufacturing process that plays a critical role in various industries. The demand for small plastic injection molds continues to rise, driving the need for advanced manufacturing techniques and innovative solutions. With its unparalleled expertise, commitment to innovation, and exceptional customer service, {} is well-positioned to meet the evolving needs of the small plastic injection mold market and remain a leader in the industry.