Injection Molding Process for Plastic Cups: A Complete Guide

By:Admin

Leading plastic manufacturing company, **(company name)**, has announced the launch of their latest innovation — a new injection-molded plastic cup. This new product promises to offer a durable and versatile solution for consumers and businesses alike, meeting the increasing demand for sustainable and high-quality drinkware.

The new plastic cup is designed to be both stylish and practical, integrating modern aesthetics with functional features. Made from premium quality plastic materials, the cup is lightweight, shatterproof, and reusable, making it an ideal option for both indoor and outdoor use. The company's commitment to sustainable practices is evident in their use of recyclable materials, ensuring that the cup aligns with the growing eco-consciousness of consumers.

In addition to its sustainable design, the plastic cups are also customizable, allowing businesses to create their own branded drinkware. This feature has already caught the attention of several industry leaders looking for a practical and cost-effective way to promote their businesses. By offering custom printing and branding options, **(company name)** aims to provide a solution that addresses the promotional needs of businesses while also meeting the demands of environmentally conscious consumers.

**(company name)** has a strong reputation for innovation and quality in the plastic manufacturing industry. With a legacy of excellence spanning over **(X)** years, the company has consistently led the market with its cutting-edge products and commitment to customer satisfaction. This latest release further solidifies their position as a leader in the industry, demonstrating their ability to adapt to evolving consumer needs and market trends.

In a statement, **(company name)**'s CEO expressed excitement about the new product, noting that it represents a significant step forward in the company's commitment to sustainability and innovation. "We are thrilled to introduce our new injection-molded plastic cup to the market," the CEO said. "We believe it offers a practical and eco-friendly solution for both businesses and consumers, and we are excited to see the positive impact it will have in the industry."

The company's dedication to sustainability is evident in its manufacturing processes. **(company name)** has invested in state-of-the-art technology and equipment to ensure that their products are not only high-quality but also environmentally friendly. Their commitment to reducing waste and promoting recyclable materials aligns with the growing consumer demand for sustainable products, making them a trusted choice for businesses and consumers alike.

The launch of the new plastic cup comes at a time when the demand for sustainable and customizable drinkware is on the rise. With consumers becoming increasingly conscious of the environmental impact of their purchasing decisions, businesses are looking for ways to align with these values while also achieving their branding and promotional objectives. **(company name)**'s new plastic cup is positioned to meet these dual needs, providing a practical, stylish, and eco-friendly option for businesses and consumers.

As the market for sustainable products continues to grow, **(company name)** is confident in the potential of their new injection-molded plastic cup to make a significant impact. With its customizable options, durable design, and commitment to sustainability, the product is poised to become a go-to choice for businesses looking to promote their brand in an environmentally responsible manner.

In conclusion, the unveiling of **(company name)**'s new injection-molded plastic cup marks a significant milestone for the company and the industry as a whole. By offering a sustainable, customizable, and high-quality solution, **(company name)** is demonstrating its ongoing commitment to meeting the diverse needs of businesses and consumers. This latest release further cements the company's position as a leader in plastic manufacturing, showcasing their ability to innovate and adapt to the evolving demands of the market.

Company News & Blog

Enhance Your Injection Moulding Process with a Plastics Controller

Injection moulding plastics controller is a critical component in the manufacturing industry that helps to control and regulate the injection moulding process. It plays a pivotal role in ensuring the quality and consistency of the final plastic products. As the demand for high-quality plastic products continues to grow, the need for advanced injection moulding plastics controllers becomes increasingly important.One company that has been at the forefront of developing and supplying top-notch injection moulding plastics controllers is {}. With years of experience and expertise in the manufacturing industry, {} has established itself as a reliable and trusted provider of injection moulding solutions.{} is committed to delivering innovative and high-performance injection moulding plastics controllers that meet the diverse needs of its customers. The company's dedication to quality and excellence has earned it a strong reputation in the industry. Its products are known for their reliability, accuracy, and efficiency, making them a preferred choice for many manufacturers around the world.One of the key features of {}’s injection moulding plastics controllers is their advanced technology and user-friendly interface. The company continuously invests in research and development to improve and refine its products, ensuring that they remain at the cutting edge of technology. This commitment to innovation enables {} to provide its customers with state-of-the-art injection moulding solutions that enhance their production processes and overall efficiency.Moreover, {} understands the importance of customization in the manufacturing industry. The company offers a range of injection moulding plastics controllers that can be tailored to meet specific requirements and applications. This flexibility allows customers to optimize their manufacturing processes and achieve the best possible results.In addition to its high-quality products, {} is also known for its exceptional customer service. The company's team of experts is dedicated to providing in-depth technical support and guidance to ensure that customers get the most out of their injection moulding plastics controllers. {} understands the challenges and complexities of the manufacturing industry and is committed to helping its customers overcome them.The demand for injection moulding plastics controllers is expected to grow in the coming years as the manufacturing industry continues to expand. As companies strive to improve their production processes and deliver high-quality products, the need for reliable and efficient injection moulding solutions will only increase. {} is well-positioned to meet this growing demand with its cutting-edge products and unwavering commitment to customer satisfaction.With a strong track record of delivering top-quality injection moulding plastics controllers and a customer-centric approach, {} is poised to remain a key player in the industry. The company's focus on innovation, customization, and customer support sets it apart from its competitors and positions it as a leader in the injection moulding market.In conclusion, injection moulding plastics controllers are essential components in the manufacturing industry, and {} has established itself as a leading provider of these critical solutions. With its high-quality products, advanced technology, and exceptional customer service, {} is well-equipped to meet the evolving needs of the industry and continue to be a trusted partner for manufacturers worldwide.

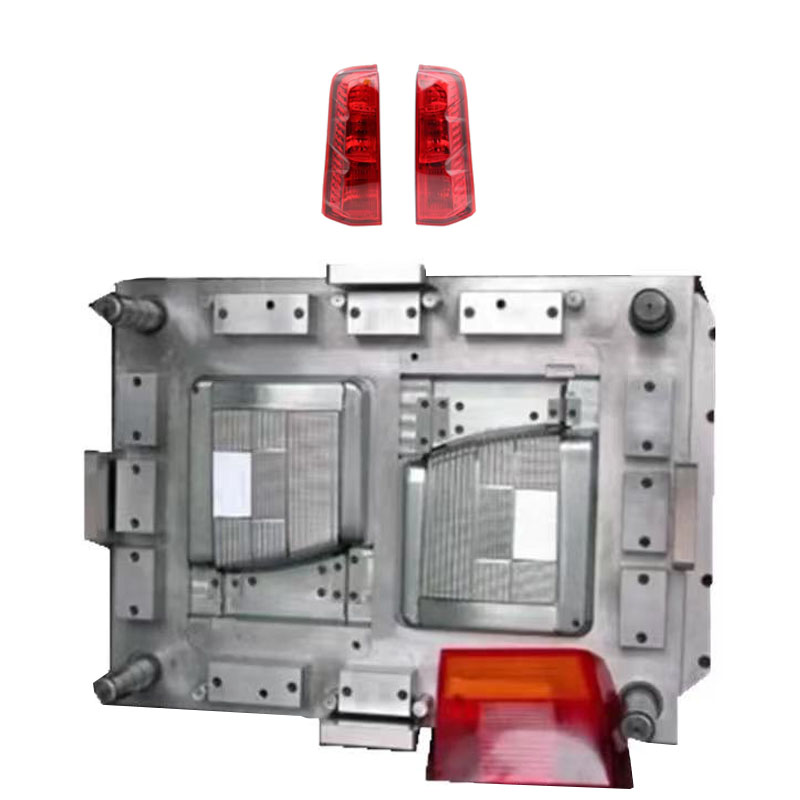

High-Quality Large Plastic Injection Mold for Manufacturing

Large Plastic Injection Mold (brand name removed) Unveils New Innovation The renowned plastic injection mold manufacturer, (Company Name), has recently unveiled its latest innovation – a large plastic injection mold that is set to revolutionize the industry. The new mold is designed to meet the growing demand for larger and more complex plastic components, and is expected to provide unprecedented opportunities for manufacturers in a wide range of industries.With over (number of years) of experience in the plastic injection mold industry, (Company Name) has established itself as a leader in innovation and quality. The company's commitment to research and development has resulted in the creation of some of the most advanced and reliable injection molds in the market. The unveiling of the new large plastic injection mold is a testament to the company's dedication to pushing the boundaries of what is possible in the industry.The new mold is capable of producing plastic components that are significantly larger and more complex than those produced by traditional injection molds. This opens up a world of possibilities for manufacturers, allowing them to create products that were previously thought to be impossible to manufacture using injection molding. The mold is also designed to provide improved precision and efficiency, resulting in higher quality products and reduced manufacturing costs.One of the key features of the new mold is its modular design, which allows for easy customization and adaptation to specific manufacturing requirements. This means that manufacturers can tailor the mold to their exact needs, ensuring that they are able to produce the highest quality products with maximum efficiency. The mold is also equipped with the latest technology and advanced control systems, further enhancing its capabilities and reliability.In addition to its technical features, the new large plastic injection mold is also designed with sustainability in mind. (Company Name) has integrated eco-friendly materials and processes into the production of the mold, ensuring that it meets the highest environmental standards. This commitment to sustainability reflects the company's overall ethos of responsible and ethical manufacturing practices.The unveiling of the new large plastic injection mold has already generated significant interest within the industry. Manufacturers are eager to explore the possibilities that the mold presents, and many are already in discussions with (Company Name) about potential collaborations and partnerships. The mold is expected to have a profound impact on the industry, and (Company Name) is poised to lead the way in its adoption and implementation.As the demand for larger and more complex plastic components continues to grow, the introduction of the new large plastic injection mold from (Company Name) represents a major step forward for the industry. With its cutting-edge technology, customizable design, and sustainable approach, the mold is set to redefine the possibilities of plastic injection molding and open up new opportunities for manufacturers around the world. (Company Name) continues to demonstrate its commitment to innovation and excellence, and the unveiling of this new mold is a clear testament to its leadership in the industry.

Everything You Need to Know About Plastic Molding Injection

Plastic Molding Injection, a leading provider of injection molding solutions, has been making waves in the manufacturing industry with its innovative technology and top-notch service. With a focus on quality and efficiency, the company has established itself as a go-to source for companies in need of high-quality plastic parts.Plastic Molding Injection specializes in creating custom plastic parts using injection molding technology. This process allows for the production of large quantities of plastic components with high precision and consistency. The company's state-of-the-art facilities and advanced machinery enable them to handle a wide range of projects, from small, intricate parts to large, complex components.One of the key factors that sets Plastic Molding Injection apart from its competitors is its commitment to providing superior customer service. The company works closely with its clients to understand their specific needs and requirements, ensuring that every project is completed to the highest standards. This dedication to excellence has earned Plastic Molding Injection a strong reputation in the industry and has resulted in numerous satisfied customers.In addition to its cutting-edge technology and customer-focused approach, Plastic Molding Injection also prides itself on its experienced and skilled team of professionals. The company employs highly trained and knowledgeable technicians who are experts in the field of injection molding. Their expertise and attention to detail ensure that every project is completed with precision and accuracy.Plastic Molding Injection's comprehensive services include mold design, prototype development, and full-scale production. The company is equipped to handle projects of any size, providing cost-effective solutions for clients across a wide range of industries. Whether it's automotive, medical, aerospace, or consumer goods, Plastic Molding Injection has the capabilities to meet the needs of diverse businesses.The company's dedication to sustainability and environmental responsibility is another noteworthy aspect of its operations. Plastic Molding Injection is committed to reducing its environmental impact by implementing eco-friendly practices and using recyclable materials wherever possible. This commitment to sustainability not only benefits the environment but also allows the company to offer its clients eco-conscious solutions for their plastic molding needs.Plastic Molding Injection's recent investments in new technology and equipment have further strengthened its position as a leader in the industry. The company regularly updates its machinery and processes to remain at the forefront of innovation, allowing it to deliver the highest quality products in the most efficient manner possible. This dedication to continuous improvement ensures that Plastic Molding Injection stays ahead of the curve and continues to meet the evolving needs of its clients.As the demand for high-quality plastic components continues to grow, Plastic Molding Injection is well-positioned to meet the needs of the market. The company's focus on excellence, customer satisfaction, and technological advancement make it a reliable partner for businesses seeking top-tier injection molding solutions. With its proven track record and commitment to excellence, Plastic Molding Injection is poised to remain a dominant force in the industry for years to come.

High-Quality Used Injection Mold for Plastic Manufacturing

Plastic injection molding is a process that involves heating plastic resin and then injecting it into a mold to create a desired shape. This method is widely used in the manufacturing industry to produce a variety of plastic products such as toys, packaging, automotive parts, and more. To carry out this process, companies often rely on plastic injection molds, which are crucial tools for shaping plastic materials.Recently, a leading company in the manufacturing industry, {}, has announced that it will be selling a used plastic injection mold, which has been carefully maintained and is in excellent condition. The mold, which has been used to produce high-quality plastic products, is now available for purchase, offering other companies the opportunity to enhance their own manufacturing capabilities.{} is a well-established company with a strong track record in providing custom plastic injection molding solutions to a wide range of industries. The company specializes in creating precision molds and producing high-quality plastic parts for various applications. With a team of experienced engineers and technicians, {} has gained a reputation for delivering innovative and cost-effective manufacturing solutions to its clients.The used plastic injection mold being offered for sale by {} has been specifically designed to meet the highest standards of quality and performance. With meticulous attention to detail, the mold has been carefully maintained and is in top condition, ensuring that it can continue to produce high-quality plastic parts with precision and efficiency. By making this mold available to other companies, {} aims to provide an opportunity for businesses to enhance their production capabilities and create superior plastic products.Furthermore, {} has a comprehensive understanding of the plastic injection molding process and is committed to providing ongoing support and assistance to the purchasers of the used mold. With its extensive knowledge and expertise in the field, the company is well-equipped to offer guidance on the proper use and maintenance of the mold, as well as to provide any necessary technical support to ensure its continued performance.In addition to the sale of the used plastic injection mold, {} also offers a range of other services to support the manufacturing needs of its clients. These services include custom mold design and manufacturing, plastic injection molding production, and quality assurance and inspection. By providing a comprehensive suite of solutions, {} aims to be a trusted partner for companies seeking to streamline their production processes and achieve superior results in plastic manufacturing.The availability of this used plastic injection mold presents an excellent opportunity for companies in the manufacturing industry to acquire a high-quality tool that can significantly enhance their production capabilities. With {}'s reputation for excellence and its commitment to providing ongoing support, businesses can have confidence in the value and reliability of this mold for their manufacturing operations.In conclusion, the sale of the used plastic injection mold by {} represents an exciting opportunity for companies to improve their manufacturing capabilities and produce superior plastic products. With its reputation for excellence, extensive expertise, and commitment to providing ongoing support, {} is well-positioned to offer valuable solutions to the industry. As the demand for high-quality plastic products continues to grow, this used mold presents a valuable investment for companies looking to elevate their manufacturing capabilities and achieve exceptional results.

Molding Design and Making of Hair Dryer: Everything You Need to Know

Innovative Hair Dryer Molding Design and Making Technology Revolutionizes the IndustryThe hair care industry is constantly evolving with the demand for more advanced and efficient products. As a response to this demand, {company name} has introduced an innovative approach to hair dryer molding design and making that is set to revolutionize the industry.With over 20 years of experience in the manufacturing and design of hair care products, {company name} has established itself as a leader in the industry. Their commitment to innovation and quality has led to the development of cutting-edge technologies that have set new standards for the industry.The latest advancement from {company name} comes in the form of a hair dryer molding design and making process that combines advanced materials and precision engineering to create a product that is not only more efficient but also more eco-friendly. This new technology has been developed in response to the growing demand for sustainable and environmentally friendly products in the beauty industry.One of the key features of this new technology is the use of advanced materials that are not only durable and long-lasting but also more lightweight, reducing the overall energy consumption of the hair dryers. This not only benefits the environment by reducing the carbon footprint of the product but also provides a more ergonomic and user-friendly experience for the consumers.In addition to the advanced materials, the new hair dryer molding design and making process incorporates precision engineering techniques that result in a more efficient and powerful hair dryer. The aerodynamic design of the dryer allows for faster and more even drying, reducing the overall time and energy required to achieve the desired results.Furthermore, {company name} has also incorporated advanced heat control technology into the design, allowing for more precise temperature regulation and reducing the risk of damage to the hair. This feature not only enhances the performance of the product but also ensures the safety and well-being of the consumers.This groundbreaking technology has already received widespread acclaim from industry experts and consumers alike. The CEO of {company name}, {CEO name}, stated, "We are proud to introduce this new technology that not only meets the demands of the industry but also takes a significant step towards sustainability and eco-consciousness. Our commitment to innovation and quality drives us to continue pushing the boundaries of what is possible in the hair care industry."The introduction of this new technology is a testament to {company name}'s dedication to pushing the limits of innovation and quality in the hair care industry. As a leader in the field, {company name} continues to set new standards and raise the bar for the industry as a whole.The new hair dryer molding design and making technology from {company name} is set to revolutionize the industry and set a new standard for efficiency, performance, and sustainability. With its advanced materials and precision engineering, this new technology is a testament to {company name}'s ongoing commitment to innovation and quality in the hair care industry.

Durable Mould Die for Plastic Toys - Learn More Here!

[Company Name] is a leading manufacturer of plastic injection molds, specializing in the production of high-quality plastic toys. They utilize state-of-the-art technology and innovative design concepts to create molds that meet the highest industry standards. With a commitment to precision and excellence, [Company Name] has gained a reputation for delivering top-notch products to their clients.Recently, [Company Name] announced the launch of their latest innovation in plastic toy molds – the new and improved Plastic Toys Mould Die. This cutting-edge mold die is set to revolutionize the production of plastic toys, offering enhanced efficiency and precision in the manufacturing process.The Plastic Toys Mould Die is designed to deliver superior performance, with a focus on durability and accuracy. It is engineered to withstand the rigors of high-volume production, ensuring consistent and reliable output. The die is also equipped with advanced features that enable seamless integration into existing manufacturing processes, minimizing downtime and optimizing productivity.One of the key highlights of the Plastic Toys Mould Die is its versatility. It is compatible with a wide range of plastic resins, allowing for the production of various types of toys with different characteristics. This flexibility provides manufacturers with the freedom to explore new designs and concepts, opening up endless possibilities for creativity and innovation in the toy industry.In addition to its technical capabilities, the Plastic Toys Mould Die is also designed with user convenience in mind. Its user-friendly interface and intuitive controls make it easy to operate, reducing the need for extensive training and streamlining the production workflow. This, combined with its low maintenance requirements, makes the die a cost-effective solution for toy manufacturers.“We are thrilled to introduce the Plastic Toys Mould Die to the market,” said [Spokesperson Name], [Title] of [Company Name]. “We believe that this innovation will significantly impact the way plastic toys are produced, offering our clients a competitive edge in the industry. The die is a testament to our commitment to pushing the boundaries of mold manufacturing and delivering best-in-class solutions to our customers.”The launch of the Plastic Toys Mould Die comes at a time when the demand for high-quality plastic toys is on the rise. With consumers increasingly seeking safe and durable toys for their children, manufacturers are under pressure to meet stringent quality standards. The Plastic Toys Mould Die equips them with the necessary tools to achieve this, while also improving their operational efficiency and cost-effectiveness.As the global toy market continues to expand, [Company Name] is poised to capitalize on the growing demand for plastic toys. By offering innovative solutions like the Plastic Toys Mould Die, the company aims to solidify its position as a leader in the mold manufacturing industry and strengthen its partnerships with toy manufacturers worldwide.The Plastic Toys Mould Die is now available for purchase, and [Company Name] encourages interested parties to reach out for more information. With its advanced technology and cutting-edge design, the die is set to make a significant impact on the plastic toy manufacturing landscape, driving the industry towards greater efficiency and excellence.

Custom Plastic Injection Tube Mold | Top Quality Injection Molding Services

A leading plastic injection mold company in the industry, located in (insert location), has recently introduced a new innovation in their product line - the plastic injection tube mold. This new mold is designed to meet the growing demand for high-quality plastic tube products in various industries, including packaging, medical, and consumer goods.The company, with years of experience in the plastic injection mold industry, has a strong reputation for delivering top-notch molds and satisfying customer needs. With a team of skilled engineers and technicians, the company has been able to stay ahead of the competition by constantly innovating and improving its product offerings.The new plastic injection tube mold is the latest addition to the company's extensive range of molds. With the ability to produce high-quality plastic tubes with precision and efficiency, this mold is set to revolutionize the way plastic tubes are manufactured. The mold is designed to produce tubes of various sizes and shapes, catering to the diverse needs of different industries.One of the key features of the plastic injection tube mold is its durability and longevity. Made from high-quality materials, the mold is built to withstand the rigors of continuous use, ensuring that it delivers consistent results over time. This durability, coupled with the precision engineering of the mold, ensures that every plastic tube produced is of the highest quality.In addition to its durability, the plastic injection tube mold is also designed for ease of use. With intuitive controls and a user-friendly interface, the mold can be operated with minimal training, making it accessible to a wide range of users. This user-friendly design is a testament to the company's commitment to delivering products that are not only of high quality but also easy to use.The introduction of the plastic injection tube mold is a testament to the company's dedication to innovation and excellence in the plastic injection mold industry. By continually investing in research and development, the company is able to stay at the forefront of technological advancements, ensuring that it can meet the evolving needs of its customers.Furthermore, the company's commitment to sustainability is evident in the design of the plastic injection tube mold. By optimizing the manufacturing process and minimizing waste, the mold is designed to be environmentally friendly, aligning with the company's efforts to reduce its environmental footprint.The plastic injection tube mold is already generating excitement in the industry, with many customers eager to integrate this innovative technology into their production processes. From packaging companies looking to produce high-quality plastic tubes for their products to medical device manufacturers needing precise and consistent tubing, the mold offers a versatile solution for a wide range of applications.As the demand for high-quality plastic tubes continues to grow, the introduction of the plastic injection tube mold is a timely and strategic move for the company. By staying ahead of the curve and delivering cutting-edge products, the company is well-positioned to solidify its position as a leader in the plastic injection mold industry.Overall, the introduction of the plastic injection tube mold is a testament to the company's commitment to innovation, excellence, and sustainability. With its durability, precision, and user-friendly design, the mold is set to revolutionize the way plastic tubes are manufactured, meeting the diverse needs of customers across various industries. As the company continues to push the boundaries of what is possible in the plastic injection mold industry, this latest innovation cements its reputation as a formidable force in the market.

Plastic Injection Molding for Cars: Enhancing Efficiency and Durability

[Publisher Name] - [Publication Date]Car Plastic Injection Molding: Revolutionizing the Automotive Industry[City], [State] - With advancements in technology, the automotive industry has witnessed a significant shift towards the use of durable and lightweight materials. Car plastic injection molding has emerged as a game-changer in this regard, providing unparalleled precision, cost-effectiveness, and efficiency in the production of automotive components. As the demand for more fuel-efficient vehicles rises, car plastic injection molding has become a critical process in manufacturing lightweight and environmentally-friendly automobiles.[Company Name], a leading player in the automotive industry, is at the forefront of car plastic injection molding technology. Established in [year], the company has consistently delivered innovative solutions, revolutionizing the sector. With a state-of-the-art manufacturing facility and a team of skilled engineers and technicians, they have positioned themselves as a reliable partner for automotive manufacturers. By leveraging their expertise in car plastic injection molding, [Company Name] has been instrumental in meeting the growing consumer demand for high-quality, lightweight, and visually appealing vehicle components.Car plastic injection molding is a process that involves injecting molten plastic into a mold cavity under high pressure. The plastic quickly solidifies within the mold, taking the shape of the desired component. This method offers numerous benefits when compared to traditional manufacturing processes. Firstly, it allows for the production of complex and intricate designs with precise dimensions, ensuring a perfect fit and finish. This level of precision is critical in the automotive industry, where even the slightest deviation can impact the overall functionality and safety of the vehicle.Another advantage of car plastic injection molding is its cost-effectiveness. The ability to mass-produce identical components in a short span of time significantly reduces production costs. Additionally, the versatility of this process allows for the incorporation of multiple features, such as inserts, threads, or undercuts, eliminating the need for additional assembly steps. These factors contribute to overall cost savings and increased efficiency in automotive manufacturing.Furthermore, car plastic injection molding enables the production of lightweight components without compromising on strength and durability. As automakers strive to develop more fuel-efficient vehicles, the weight reduction becomes crucial. By utilizing lightweight materials, such as plastic, the overall weight of the vehicle is reduced, leading to improved fuel efficiency and reduced carbon emissions. Additionally, plastic components are resistant to corrosion and can withstand harsh environments, ensuring the longevity of the vehicle.The automotive industry has witnessed multiple advancements in car plastic injection molding, thanks to companies like [Company Name]. One notable development is the integration of sustainable practices in the manufacturing process. [Company Name] has adopted eco-friendly materials and processes that reduce waste and promote recycling. By utilizing recycled plastic materials and employing energy-efficient machines, [Company Name] ensures a minimal carbon footprint without compromising on quality.Moreover, car plastic injection molding facilitates the production of visually appealing components. With a wide range of color options and finishes, manufacturers can create aesthetically pleasing interiors and exteriors. This level of customization enhances the overall customer experience and allows automakers to differentiate themselves in a highly competitive market.In conclusion, car plastic injection molding has become a vital process in the automotive industry as it offers precision, cost-effectiveness, and environmental sustainability. Companies like [Company Name] are leading the way in adopting this technology and revolutionizing automotive manufacturing. With the ability to produce lightweight, visually appealing, and durable components, car plastic injection molding is propelling the industry towards a greener and more efficient future.For more information about [Company Name] and their car plastic injection molding capabilities, visit their website [website].

Create unique custom injection mold figures for your business

Custom Injection Mold FiguresCustom injection mold figures are becoming increasingly popular as companies seek to create unique and eye-catching products that stand out in the marketplace. These figures are created using injection molding technology, which allows for precise and detailed designs to be produced at a rapid pace. With the ability to create highly intricate designs and complex shapes, custom injection mold figures are a versatile and cost-effective option for companies looking to produce high-quality products.One company leading the way in the production of custom injection mold figures is {}. With years of experience in the industry, {} has established itself as a trusted and reliable provider of custom injection mold figures for a wide range of industries. From action figures and collectible toys to promotional items and novelty products, {} has the expertise and the capabilities to bring any design to life through their state-of-the-art injection molding technology.{}’s team of skilled designers and engineers work closely with each client to understand their specific needs and requirements, ensuring that the final product meets their exact specifications. Using advanced 3D modeling software, the team is able to create highly detailed and accurate designs that capture the essence of the client’s vision. Once the design is finalized, it is transferred to the company’s cutting-edge injection molding machines, where it is brought to life with precision and efficiency.One of the key advantages of custom injection mold figures is the ability to produce large quantities of products in a relatively short amount of time. With {}’s advanced manufacturing capabilities, clients can order custom figures in bulk without sacrificing quality or detail. This makes custom injection mold figures an ideal option for companies looking to create promotional items or merchandise for their brand.In addition to their production capabilities, {} also offers a range of finishing and assembly services to ensure that the final product meets the highest standards of quality. From painting and decorating to packaging and assembly, {} provides end-to-end solutions for clients looking to bring their custom injection mold figures to market.With a commitment to innovation and excellence, {} continues to push the boundaries of what is possible with custom injection mold figures. By investing in the latest technology and staying ahead of industry trends, {} is able to deliver cutting-edge solutions that meet the needs of their clients and exceed their expectations.As the demand for custom injection mold figures continues to grow, {} is poised to remain at the forefront of the industry, providing high-quality products and exceptional service to their clients. Whether it’s creating unique collectible toys or producing custom promotional items, {} has the expertise and the resources to bring any design to life through their custom injection mold figures.In conclusion, custom injection mold figures are a versatile and cost-effective option for companies looking to create unique and eye-catching products. With their advanced technology and dedication to excellence, {} is a leading provider of custom injection mold figures, offering high-quality solutions for a wide range of industries. Whether it’s action figures, collectible toys, or promotional items, {} has the expertise and the capabilities to bring any design to life through their state-of-the-art injection molding technology.

High-Quality Injection Moulds for Plastic Wall Plugs: A Comprehensive Guide

Injection Moulds For Plastic Wall Plugs: A Breakthrough in Manufacturing TechnologyIn the world of manufacturing and construction, the use of plastic wall plugs has become increasingly popular due to their versatility and durability. These small but essential components play a crucial role in securing fixtures and fittings to walls, providing a reliable anchor for screws and bolts. As the demand for plastic wall plugs continues to rise, manufacturers are constantly seeking innovative ways to improve the efficiency and quality of production. This is where the injection moulding technology comes into play, revolutionizing the manufacturing process and setting new standards in the industry.One company at the forefront of this groundbreaking technology is {}. With decades of experience in the field of injection moulding, {} has established itself as a leading provider of high-quality moulds and machinery for the production of plastic components. The company's commitment to innovation and continuous improvement has led to the development of state-of-the-art injection moulds specifically designed for plastic wall plugs.The injection moulding process involves the use of a moulding machine to inject molten plastic into a mould cavity, where it is cooled and hardened to form the desired shape. With the advancement of technology, injection moulding has become the preferred method for manufacturing plastic parts due to its speed, precision, and cost-effectiveness. {}The injection moulds for plastic wall plugs developed by {} are engineered to deliver exceptional performance and reliability. These moulds are meticulously designed to ensure the accurate and consistent production of wall plugs with precise dimensions and superior structural integrity. The use of high-quality materials and advanced machining techniques results in durable moulds that can withstand the rigors of high-volume production.One of the key advantages of the injection moulds offered by {} is their versatility. These moulds are designed to accommodate various sizes and configurations of plastic wall plugs, enabling manufacturers to produce a wide range of products to meet diverse application requirements. Whether it's a standard-sized wall plug for general use or a specialized plug for specific construction projects, {} has the capability to deliver customised moulds tailored to the unique needs of its customers.Moreover, {} takes pride in its commitment to sustainability and environmental responsibility. The company has incorporated eco-friendly practices into its manufacturing processes, ensuring that the injection moulds for plastic wall plugs are produced with minimal impact on the environment. By prioritizing energy efficiency and waste reduction, {} is dedicated to promoting a greener and more sustainable future for the manufacturing industry.With the introduction of these cutting-edge injection moulds, {} is poised to set a new benchmark for the production of plastic wall plugs. The company's relentless pursuit of excellence and its dedication to technological advancements have positioned it as a trusted partner for manufacturers seeking the highest standards of quality and performance in their production processes.In conclusion, the development of injection moulds for plastic wall plugs by {} represents a significant advancement in manufacturing technology. With a focus on precision, versatility, and sustainability, {} has redefined the standards for producing plastic wall plugs, offering a reliable solution for the construction and manufacturing industries. As the demand for high-quality plastic wall plugs continues to grow, {} remains committed to driving innovation and delivering superior moulding solutions that meet the evolving needs of its customers.