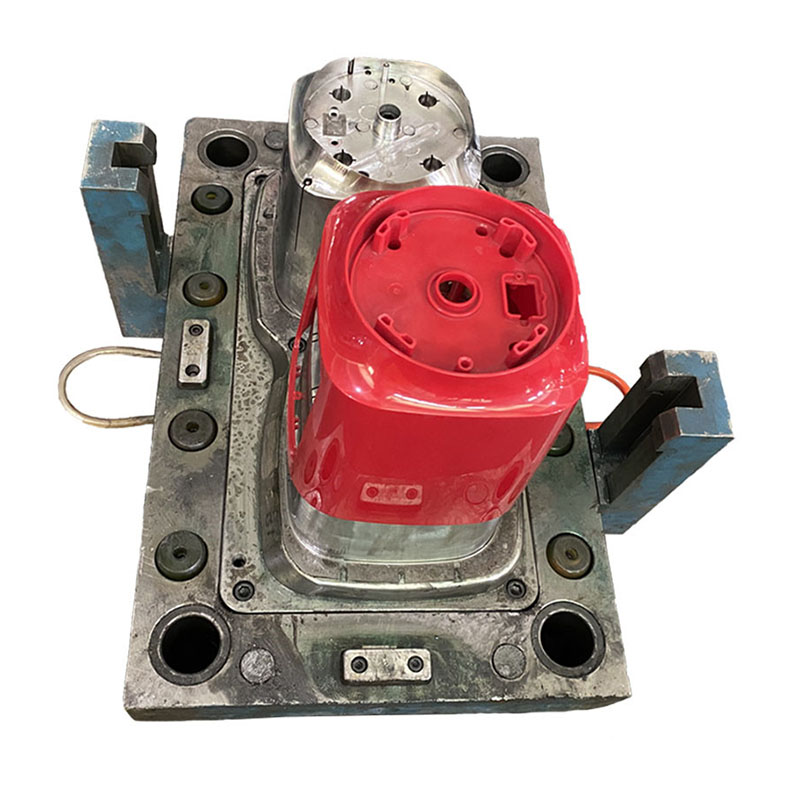

Injection Moulding Machine for Plastic Box Manufacturing

By:Admin

In today's fast-paced and demanding manufacturing industry, efficiency and precision are crucial to keep up with the growing demands of consumers. This is where the Plastic Box Injection Moulding Machine from [Company Name] comes into play.

[Company Name], a leading manufacturer of injection moulding machines, has been at the forefront of innovation in the industry for over 20 years. With a strong focus on research and development, [Company Name] has consistently provided cutting-edge solutions to help businesses streamline their manufacturing processes.

The Plastic Box Injection Moulding Machine is one such innovation that has been making waves in the industry. This state-of-the-art machine is designed to meet the ever-growing demand for high-quality plastic boxes in various industries, including food and beverage, logistics, and storage.

With its robust construction and advanced technology, the Plastic Box Injection Moulding Machine offers unparalleled precision and efficiency. Its high-speed and high-pressure injection system ensures fast and accurate moulding, resulting in consistently high-quality plastic boxes.

The machine also boasts a user-friendly interface and intuitive controls, making it easy for operators to set and adjust parameters as needed. This not only saves time but also reduces the likelihood of errors, contributing to a smoother and more efficient production process.

One of the standout features of the Plastic Box Injection Moulding Machine is its versatility. It can accommodate a wide range of mould sizes and configurations, allowing businesses to produce plastic boxes of various shapes and sizes without the need for major retooling or adjustments.

Furthermore, the machine is equipped with advanced safety features, ensuring the well-being of operators and the longevity of the equipment. [Company Name] takes pride in providing reliable and durable machinery that can withstand the rigors of continuous production.

The environmental impact of the Plastic Box Injection Moulding Machine has also been a key focus for [Company Name]. With a commitment to sustainability, the machine is designed to minimize energy consumption and material waste, aligning with the growing demand for eco-friendly manufacturing practices.

[Company Name] has also placed a strong emphasis on after-sales service and support, providing comprehensive training and technical assistance to ensure the seamless integration of the Plastic Box Injection Moulding Machine into the production lines of their clients. This dedication to customer satisfaction has cemented [Company Name]'s reputation as a trusted partner in the manufacturing industry.

The positive reception of the Plastic Box Injection Moulding Machine is a testament to [Company Name]'s unwavering commitment to innovation and excellence. Businesses that have adopted the machine have reported significant improvements in their production efficiency, product quality, and overall competitiveness in the market.

Looking ahead, [Company Name] continues to push the boundaries of injection moulding technology, with ongoing research and development aimed at addressing the evolving needs of the industry. The company's dedication to innovation and customer satisfaction is poised to solidify its position as a leader in the manufacturing sector.

In conclusion, the Plastic Box Injection Moulding Machine from [Company Name] is revolutionizing the way plastic boxes are manufactured. Its advanced technology, versatility, and commitment to sustainability make it a game-changer for businesses seeking to stay ahead in an increasingly competitive market. With a proven track record of excellence, [Company Name] is set to continue shaping the future of the manufacturing industry with its innovative solutions.

Company News & Blog

Plastic Chair Shell Injection Mold: Creating Stylish Seating Solutions

[Plastic Chair Shell Injection Mold]In recent years, the plastic industry has witnessed significant growth, owing to the increasing demand for alternative materials that are lightweight, durable, and cost-effective. Among the numerous plastic products, plastic chairs have emerged as one of the most sought-after items due to their versatility and functionality. To cater to the growing needs of the market, companies like [Company Name] have pioneered the manufacturing of plastic chair shells using advanced injection mold technology.Injection molding has revolutionized the production process of plastic products, making it efficient, precise, and capable of creating complex designs. The plastic chair shell injection mold developed by [Company Name] has been widely acclaimed in the industry for its exceptional quality and impeccable craftsmanship. Through meticulous research and development, the company has managed to create molds that are not only durable but also aesthetically pleasing.The secret behind the success of [Company Name]'s plastic chair shell injection mold lies in its commitment to innovation and state-of-the-art technology. The company employs a team of highly-skilled engineers and designers who continuously strive to enhance the mold's design and functionality. By utilizing computer-aided design and manufacturing (CAD/CAM) software, they are able to create precise prototypes and optimize the mold's performance, resulting in a superior end product.Furthermore, [Company Name] understands the significance of using eco-friendly materials in today's environmentally conscious world. Their injection molds are crafted using high-quality, recyclable plastics, minimizing the environmental impact and fostering sustainability. The company aims to contribute to the global efforts in reducing plastic waste through their manufacturing processes.In terms of production capacity, [Company Name] boasts a highly advanced manufacturing facility equipped with cutting-edge machinery. This enables them to meet the growing demand for plastic chair shells without compromising on the quality or delivery timelines. By streamlining their production process and adhering to strict quality control measures, they ensure that every chair shell that comes out of their mold is of the highest standard.To cater to the diverse requirements of their clients, [Company Name] offers a wide range of design options and customization features. Clients can choose from an array of colors, textures, and finishes to create chair shells that align perfectly with their brand identity or interior design. This flexibility, coupled with the durability and affordability of their injection molds, has made [Company Name] a preferred choice for many furniture manufacturers worldwide.The success of [Company Name]'s plastic chair shell injection mold can be attributed to its continuous focus on research and development, commitment to excellence, and customer-centric approach. By staying ahead of market trends and embracing technological advancements, the company has managed to carve a niche for itself in the fiercely competitive plastic industry.Looking ahead, [Company Name] aims to further expand its product portfolio by developing innovative molds for a wide range of plastic products. Through their cutting-edge technology and unwavering dedication to quality, they aspire to become a global leader in the field of plastic injection molding.In conclusion, the plastic chair shell injection mold developed by [Company Name] represents a significant breakthrough in the plastic industry. With its superior quality, eco-friendly materials, and customizable design options, it has set new industry standards for manufacturing plastic chair shells. As the demand for plastic furniture continues to rise, companies like [Company Name] play a crucial role in delivering innovative solutions that meet the evolving needs of the market.

Plastic Toy Mold Swing Car: A Fun and Thrilling Ride for Kids

Plastic Toy Used Mould Swing Car - A New Innovation in Fun and EntertainmentIn recent years, the toy industry has witnessed a surge in innovative and captivating toys that seek to capture the imagination of children and provide them with hours of entertainment. One such remarkable innovation is the Plastic Toy Used Mould Swing Car, a toy that combines the thrill of riding with the maneuverability of a swing. Let us delve deeper into this exciting new product and learn more about the company behind its creation.The Plastic Toy Used Mould Swing Car, an exceptional feat of design and engineering, provides children with a unique and exhilarating experience. Combining the elements of a traditional swing and a ride-on car, this toy offers unparalleled fun and excitement. Its distinctive feature is the ability to swing left and right while propelling forward, without the need for pedals or batteries. This motion is achieved by lightly rotating the steering wheel, creating a rhythmic swinging motion that is both empowering and exhilarating for children.Designed with the safety and comfort of children in mind, the Plastic Toy Used Mould Swing Car is built from high-quality plastic material that is durable and able to withstand the rigors of play. It incorporates a sturdy and stable base, ensuring that children can enjoy a smooth ride without any fear of tipping over. Additionally, the car is ergonomically designed, providing a comfortable seating position and easy grip steering wheel for children of all ages.The versatility of the Plastic Toy Used Mould Swing Car is another feature that sets it apart from other ride-on toys. It can be used both indoors and outdoors, making it suitable for use in a wide range of environments. Whether it is in the backyard, the park, or even inside the house on a rainy day, children can enjoy endless hours of fun and entertainment. Moreover, the compact size of the toy allows for easy storage and transportation, making it a convenient option for families on the go.Now, let us introduce the company behind this groundbreaking innovation. {} is a renowned manufacturer and supplier of high-quality toys, catering to the needs and demands of children worldwide. With a rich history spanning several decades, the company has established itself as a leader in the toy industry, consistently delivering products that exceed customer expectations.Committed to providing safe and educational toys, {} employs a team of skilled designers and engineers who are passionate about creating innovative and captivating products. Rigorous quality control measures ensure that each toy undergoes thorough testing to meet international safety standards, giving parents peace of mind as their children indulge in play.In addition to their commitment to safety, {} places great emphasis on environmental sustainability. Understanding the impact of plastic waste on the planet, the company utilizes recycled and eco-friendly materials whenever possible, minimizing their carbon footprint. By adopting sustainable practices, {} demonstrates their dedication to preserving the environment for future generations.The introduction of the Plastic Toy Used Mould Swing Car is a testament to {}'s relentless pursuit of excellence and innovation. With its unique design, exceptional safety features, and versatility, this toy promises to captivate the hearts and imaginations of children around the world.In conclusion, the Plastic Toy Used Mould Swing Car is a remarkable addition to the world of toys, providing children with an unforgettable and thrilling play experience. With the commitment to safety and sustainability demonstrated by {}, parents can rest assured that their children are engaging in play that is both enjoyable and responsible. As children embark on thrilling swinging adventures, their smiles and laughter will serve as a testament to the success of this remarkable toy.

Plastic Box Injection Moulding Machine: The Latest Advancements in the Industry

Title: Innovating Plastic Box Production with Advanced Injection Moulding TechnologyIntroductionIn the ever-evolving world of manufacturing, plastic injection moulding has emerged as a versatile and efficient solution for producing a wide range of products. The Plastic Box Injection Moulding Machine has revolutionized the industry, with its state-of-the-art technology and capability to deliver high-quality plastic boxes in large quantities. This article explores the profound impact this machine is having on the manufacturing sector, both in terms of productivity and sustainability.The InnovationThe Plastic Box Injection Moulding Machine, developed by a leading manufacturing technology company, has garnered attention for its exceptional performance and cutting-edge capabilities. This advanced machinery utilizes computer numerical control (CNC) technology, which ensures precise and consistent moldings throughout the production process.The machine is equipped with high-speed servo motors that provide not only accurate injection speeds but also efficient energy consumption. This innovative feature significantly reduces production costs and minimizes material waste, making it an environmentally friendly choice. The machine's automatic lubrication system and self-cleaning mechanism further enhance its operational efficiency, reducing downtime and maintenance requirements.Improved Productivity and VersatilityThe Plastic Box Injection Moulding Machine boasts a high production capacity, enabling manufacturers to meet the increasing demand for plastic boxes in a timely manner. With its rapid operation and quick cycle times, it can produce a large number of plastic boxes in a short span, effectively reducing lead times and increasing overall productivity.Moreover, this versatile machine can accommodate a variety of molds, allowing the production of plastic boxes in various sizes, shapes, and designs. It offers flexibility to manufacturers, enabling them to cater to diverse market requirements and customer preferences. This adaptability ensures that businesses can meet the ever-changing demands of the industry, thus enhancing their competitive edge.Sustainability and Material EfficiencyWith growing concerns over environmental sustainability, the Plastic Box Injection Moulding Machine addresses these challenges by optimizing material usage. The machine utilizes an advanced injection system that precisely controls the amount of plastic injected into the mold. This feature reduces material waste and ensures each plastic box is manufactured with minimal material usage, maximizing resource efficiency.Furthermore, the machine allows for the use of recycled plastics, contributing to the circular economy. It can process a range of plastic polymers, including polyethylene (PE), polypropylene (PP), and polystyrene (PS), thereby reducing the reliance on virgin plastics. By promoting the use of recycled materials, the machine actively contributes to reducing plastic waste and lowering the overall carbon footprint of the manufacturing process.Impact on the IndustryThe Plastic Box Injection Moulding Machine's exceptional features and capabilities have revolutionized the plastic box manufacturing industry. Its high production capacity, precision, and adaptability have led to increased efficiency, reduced lead times, and improved product quality.Moreover, the machine's commitment to sustainability aligns with global efforts to reduce plastic waste and pollution. By optimizing material usage and promoting the use of recycled plastics, it plays a significant role in creating a more sustainable manufacturing sector.ConclusionThe Plastic Box Injection Moulding Machine represents a remarkable innovation in the manufacturing industry. With its cutting-edge technology, versatility, and commitment to sustainability, it has transformed the production of plastic boxes. From enhanced productivity and material efficiency to reduced carbon footprint, this machine continues to shape the industry and lead the way towards a more sustainable future.

Discover the Latest High Precision Plastic Injection Molding Parts

[Company Name] Empowers Industries with High Precision Plastic Injection Molding Parts[date][City, State] - [Company Name], a leading provider of high precision plastic injection molding parts, is revolutionizing the manufacturing sector with its cutting-edge technology and expertise. With a focus on delivering impeccable quality and unmatched precision, [Company Name] is poised to empower industries with its innovative solutions.Plastic injection molding is a widely used manufacturing process that has transformed various industries by creating complex and intricate parts with high accuracy and efficiency. The process involves injecting molten plastic into a mold cavity, which then solidifies to form the desired component. [Company Name] has mastered this technique, guaranteeing precise and consistent results every time.The secret to [Company Name]'s success lies in its state-of-the-art manufacturing facility, equipped with the latest machinery and technology. The company utilizes advanced computer-aided design (CAD) software and computer numerical control (CNC) machines for producing molds with exceptional precision. This allows [Company Name] to create intricate parts that meet even the most demanding specifications.Furthermore, [Company Name] takes great pride in its team of highly skilled technicians and engineers. They possess a deep understanding of plastic injection molding and are committed to delivering superior quality products. With their expertise, [Company Name] consistently produces high-grade plastic parts that meet or exceed industry standards.As a leader in the plastic injection molding industry, [Company Name] caters to a wide range of sectors, including automotive, electronics, medical, and consumer goods. The company's extensive product portfolio includes components such as housings, connectors, gears, and various other complex parts. These parts are used in critical applications where precision and durability are paramount.In addition to its dedication to precision and quality, [Company Name] also places a strong emphasis on sustainability. The company recognizes the importance of minimizing its environmental impact and actively seeks ways to reduce waste and energy consumption. By adopting eco-friendly practices, such as recycling and using bio-based materials, [Company Name] aims to contribute to a greener and more sustainable future.To ensure the highest level of customer satisfaction, [Company Name] provides comprehensive support throughout the entire manufacturing process. From initial design and prototyping to final production, the company works closely with its clients, offering expert advice and guidance. This collaborative approach allows [Company Name] to tailor its solutions according to the specific needs and requirements of each customer.As testament to its dedication to excellence, [Company Name] has earned numerous certifications and accolades, including ISO 9001 and ISO 14001. These certifications validate the company's commitment to quality management and environmental stewardship, further instilling confidence in its customers.With its relentless pursuit of perfection, [Company Name] is poised to make a significant impact on the manufacturing sector. By offering high precision plastic injection molding parts and embracing sustainable practices, the company is driving innovation and transforming industries. Whether it's enhancing automotive performance, improving medical devices, or enabling cutting-edge electronics, [company name] is revolutionizing the way industries operate.In conclusion, [Company Name] is revolutionizing the manufacturing sector with its high precision plastic injection molding parts. Through advanced technology, a skilled workforce, and a commitment to sustainability, the company is empowering industries and driving innovation. With its unwavering dedication to excellence, [Company Name] is set to continue its growth and make a lasting impact on the global manufacturing landscape.

The Complete Guide to Mould Injection Plastic: Everything You Need to Know

Mould Injection Plastic, also known as injection molding, is a manufacturing process for producing parts by injecting molten material into a mold. This process is commonly used in the production of various plastic products, such as automotive parts, toys, packaging, and many more.One company that excels in mould injection plastic technology is {}. The company has been in the plastics industry for over 30 years and has established itself as a leading manufacturer and supplier of plastic products.At {}, they specialize in providing customized mould injection plastic solutions for their clients. With state-of-the-art machinery and a team of experienced engineers, they are able to produce high-quality plastic parts that meet the specific requirements of their customers.The company's commitment to quality and innovation has allowed them to build a strong reputation in the industry. They work closely with their clients to understand their needs and provide them with the best possible solutions. Whether it's a small batch of customized plastic parts or a large-scale production run, {} has the expertise and capabilities to deliver.In addition to their mould injection plastic services, {} also offers a range of secondary operations, such as assembly, printing, and packaging. This allows them to provide their clients with a complete solution for their plastic product needs.One of the key advantages of mould injection plastic is its ability to produce complex and intricate parts with high precision. This is especially valuable in industries such as automotive and electronics, where tight tolerances and consistent quality are essential.With a focus on continuous improvement and investment in the latest technology, {} is able to stay ahead of the competition and offer its clients the most advanced mould injection plastic solutions available in the market.In recent years, {} has also been investing in sustainable and environmentally friendly practices. They are committed to reducing their environmental impact by improving energy efficiency and minimizing waste in their manufacturing processes.As the demand for plastic products continues to grow, the need for reliable and high-quality mould injection plastic services will only increase. With its decades of experience and commitment to excellence, {} is well positioned to meet this growing demand and continue to be a trusted partner for its clients.In conclusion, mould injection plastic is a crucial technology for the production of a wide range of plastic products, and {} is at the forefront of providing top-notch mould injection plastic solutions for its clients. With its commitment to quality, innovation, and sustainability, {} is poised to continue its success in the plastics industry for many years to come.

Ultimate Guide to Precision Plastic Injection Molds: Everything You Need to Know

[Company Name], a Leader in Precision Plastic Injection Molds, Revolutionizes the Manufacturing Industry[date]In today's competitive manufacturing industry, it is imperative for companies to stay at the forefront of technological advancements and provide high-quality products efficiently. Without a doubt, Precision Plastic Injection Mold (need remove brand name) has proven to be an influential player in this domain, setting industry standards and driving innovation. With a rich history of providing exceptional plastic injection molds, (Company Name) continues to revolutionize the manufacturing industry.Established in (year), (Company Name) has grown from a small operation to become a renowned leader in precision plastic injection molds. With expertise in designing and producing high-performance molds, the company has successfully met the ever-increasing demands of its clients in multiple sectors, including automotive, consumer electronics, medical devices, and industrial applications.What sets (Company Name) apart is its commitment to continuous improvement and innovation, ensuring that it remains ahead of the curve. The company's cutting-edge facilities are equipped with state-of-the-art manufacturing technologies, including Computer-Aided Design (CAD) software, Computer Numerical Control (CNC) machining centers, and advanced measurement equipment. This investment in modern technology helps (Company Name) to efficiently produce molds with intricate designs, high precision, and optimal performance.Furthermore, (Company Name)'s team of experienced engineers and designers collaborates closely with clients to understand their specific requirements and translate them into customized mold solutions. By employing a customer-centric approach, the company ensures that its molds meet the highest standards and are tailored to the unique needs of each application. With their expertise and creativity, (Company Name) consistently delivers molds that optimize production efficiency, reduce costs, and enhance product quality.Quality is of paramount importance at (Company Name). The company follows strict quality control measures at every stage of the manufacturing process, adhering to international standards and certifications. Molds manufactured by (Company Name) undergo rigorous testing to guarantee their reliability and durability. This commitment to quality has earned the company a stellar reputation as a trusted partner among its global clientele.Sustainability is another key focus for (Company Name). Recognizing the growing concern for environmental conservation, the company adopts eco-friendly practices throughout its operations. By utilizing recyclable materials and optimizing energy consumption, (Company Name) minimizes its environmental impact without compromising on the quality and performance of its molds. This dedication to sustainable manufacturing contributes to a greener future for the industry and the world.In line with its commitment to innovation, (Company Name) also invests heavily in research and development. The company's dedicated R&D team continuously explores new materials, manufacturing techniques, and design concepts to pioneer groundbreaking solutions. By staying at the forefront of technology, (Company Name) consistently introduces advanced mold designs with enhanced features, optimized cycle times, and reduced production costs, giving its clients a competitive edge in the market.With an impressive track record and an unwavering commitment to excellence, (Company Name) is poised to lead the manufacturing industry into the future. As the demand for precision plastic injection molds continues to grow, the company is well-positioned to meet these challenges head-on, providing industry-leading solutions that drive productivity and efficiency.In conclusion, (Company Name) has solidified itself as a frontrunner in the precision plastic injection mold industry, delivering innovative solutions that redefine manufacturing processes. With cutting-edge technology, a customer-centric approach, and a focus on quality and sustainability, the company continues to push boundaries and set new standards. As the manufacturing industry evolves, (Company Name) remains at the forefront of progress, shaping the future of precision plastic injection molds.

Key Insights and Advancements in Plastic Injection Molding

[Company Name], a Leading Provider of Plastic Injection Molds, Continues to Pave the Way in Innovative Manufacturing Solutions[City, Date] - Plastic Injection Mold (PIM) production has been an essential aspect of the manufacturing industry for many years. It plays a pivotal role in meeting the demand for high-quality plastic products across various sectors. A company at the forefront of delivering cutting-edge plastic injection molds is [Company Name].With over [number of years] years of industry experience, [Company Name] has established itself as a trusted provider of top-notch plastic injection molds. Their commitment to innovation and customer satisfaction has placed them in a league of their own, consistently delivering exceptional results.Headquartered in [City], [Company Name] boasts a state-of-the-art manufacturing facility equipped with the latest technology and machinery. This allows them to offer an extensive range of plastic injection mold services to cater to the diverse needs of their clients.One of the key factors that sets [Company Name] apart from its competitors is their team of highly skilled and experienced engineers and technicians. These professionals possess a deep understanding of the intricacies of plastic injection molding and are adept at designing molds that optimize both efficiency and quality.By collaborating closely with clients, [Company Name] ensures that the molds they produce align perfectly with the specific requirements of the end product. They leverage cutting-edge software tools and a meticulous design process to craft molds that are not only durable but also capable of producing consistently high-quality products.In addition to their expertise in mold design, [Company Name] also places utmost importance on using high-quality materials. They source materials from trusted suppliers, ensuring that every mold exhibits excellent durability and longevity. By prioritizing the use of superior materials, [Company Name] ensures that their molds can withstand the demanding requirements of high-volume production.One of the standout features of [Company Name] is their commitment to keeping abreast of the latest industry trends and technological advancements. They continually invest in research and development, exploring new materials, processes, and technologies to stay ahead of the curve. This dedication to innovation allows them to offer their clients the most cutting-edge solutions, enhancing productivity and efficiency.[Company Name]'s dedication to customer satisfaction is reflected in their comprehensive after-sales support. They offer ongoing technical assistance and maintenance services to ensure the molds continue to perform optimally throughout their lifecycle. This commitment to building long-term partnerships enables [Company Name] to become a trusted collaborator for manufacturing companies worldwide.As a market leader in plastic injection mold production, [Company Name] has an impressive portfolio of successful projects across diverse industries such as automotive, healthcare, consumer goods, and more. Their molds have played a crucial role in shaping countless products that have become integral parts of our daily lives.With an unwavering commitment to quality, innovation, and customer satisfaction, [Company Name] continues to pave the way in the plastic injection mold industry. By combining their technical expertise, state-of-the-art facility, and keen eye for industry trends, they are pushing the boundaries of what is possible in plastic manufacturing.[Company Name]'s dedication to delivering top-notch plastic injection molds has earned them the trust and confidence of clients worldwide. As they strive to set new industry standards, there is no doubt that [Company Name] will continue to be at the forefront of the global plastic injection mold market.About [Company Name]:[Company Name] is a renowned provider of plastic injection molds, offering a comprehensive range of services to clients across various industries. With a focus on innovation, superior materials, and excellent customer support, [Company Name] has established itself as a trusted partner for manufacturing companies worldwide. For more information, please visit their website at [Company Website].Press Contact:[Name][Title][Phone Number][Email Address]

High-Quality Injection Plastic Mould for Chairs - Everything You Need to Know

Injection Plastic Mould For ChairThe injection plastic mould for chair has become an essential tool for companies in the furniture industry. This technology allows for the mass production of high-quality chairs at an efficient and cost-effective manner. With the increasing demand for durable and comfortable chairs, the use of injection plastic moulds has revolutionized the way chairs are made and has become a game-changer for the industry.[Company] has been a pioneer in the development and production of injection plastic moulds for chairs. With over [number] years of experience, they have established themselves as a leading provider of moulds and have played a significant role in shaping the future of the furniture industry. Their commitment to innovation and quality has earned them a solid reputation in the market, and they continue to push the boundaries of what is possible in chair production.Injection plastic moulds offer numerous advantages over traditional methods of chair production. They allow for the creation of complex and intricate designs that would be difficult or impossible to achieve using other methods. This opens up a world of possibilities for designers and manufacturers, who are now able to create chairs that are both aesthetically pleasing and functional. Additionally, the use of injection moulds results in chairs that are more consistent in quality and durability, ensuring that customers receive a product that meets their expectations.The process of creating a plastic mould for a chair begins with the design phase. This is where [Company] excels, as their team of experienced engineers and designers work closely with clients to bring their vision to life. Using advanced software and cutting-edge technology, they are able to develop highly detailed and precise mould designs that are tailored to the specific needs of the customer. This attention to detail is what sets [Company] apart and has allowed them to become a preferred partner for many furniture manufacturers.Once the design is finalized, the mould is created using state-of-the-art machinery and equipment. This is a precise and delicate process that requires expert craftsmanship and precision. [Company] has invested heavily in their manufacturing capabilities, ensuring that they have the tools and resources needed to produce high-quality moulds that meet the strictest standards of quality and performance. As a result, they are able to deliver moulds that are reliable, durable, and capable of withstanding the rigors of mass production.The final step in the process is the injection of plastic into the mould. This is where the magic happens, as the mould is filled with molten plastic and allowed to cool and harden. The result is a chair component that is strong, lightweight, and ready for assembly. The use of injection moulds ensures that each chair component is consistent in quality and dimensions, leading to a finished product that is reliable and visually appealing.Injection plastic moulds have had a profound impact on the furniture industry, and [Company] has been at the forefront of this transformation. Their dedication to innovation and quality has made them a trusted partner for many furniture manufacturers, and their moulds have helped to revolutionize the way chairs are made. As the demand for durable and stylish chairs continues to grow, the use of injection plastic moulds will undoubtedly play a crucial role in meeting this demand and shaping the future of the industry. With their expertise and commitment to excellence, [Company] is poised to remain a leader in the development and production of injection plastic moulds for chairs, driving innovation and helping to bring new and exciting designs to the market.

Ultimate Guide to Plastic Injection Molding PVC Techniques and Benefits

[Company Name] Leads the Way in Plastic Injection Molding with PVCWith the increasing demand for high-quality plastic products in various industries, [Company Name] stands out as a leader in the field of plastic injection molding. The company has established a reputable name for itself by offering innovative solutions and top-notch products, particularly in the use of PVC - a versatile and durable material.[Company Name] has been in the plastics manufacturing industry for over [Number] years, and has emerged as a trusted partner for businesses looking for custom plastic injection molding solutions. The company's state-of-the-art facility and team of experienced engineers and technicians enable them to offer a wide range of services, including design assistance, mold making, and production of precision plastic components.One of the key aspects that set [Company Name] apart from its competitors is its expertise in working with PVC. PVC, or polyvinyl chloride, is a widely used thermoplastic polymer that is known for its excellent properties such as strength, chemical resistance, and affordability. [Company Name] has mastered the art of plastic injection molding with PVC, and can produce a diverse array of products using this material. From consumer goods and automotive components to medical devices and electrical parts, [Company Name] has the capability to fulfill the diverse needs of its clients across various industries.In addition to its expertise in PVC injection molding, [Company Name] prides itself on its commitment to sustainability and environmental responsibility. The company is dedicated to using recycled materials and minimizing waste in its production processes. By adopting eco-friendly practices, [Company Name] not only reduces its environmental footprint but also helps its clients meet their sustainability goals.Furthermore, [Company Name] is constantly investing in the latest technology and equipment to stay ahead of the curve in the rapidly evolving plastics industry. The company's dedication to continuous improvement and innovation ensures that it stays at the forefront of plastic injection molding, offering its clients the most cutting-edge solutions."We are passionate about delivering the highest quality products to our clients," says [Spokesperson's Name], the CEO of [Company Name]. "Our commitment to excellence and our expertise in PVC injection molding have positioned us as a preferred partner for businesses seeking reliable and efficient plastic manufacturing solutions."Through its strong emphasis on quality, customer satisfaction, and environmental stewardship, [Company Name] has established itself as a leading force in the plastic injection molding industry. With its focus on PVC as a versatile and durable material, [Company Name] is well-equipped to meet the evolving needs of its clients across diverse industries.As the demand for high-quality plastic products continues to grow, [Company Name] remains dedicated to providing innovative and sustainable solutions through its expertise in PVC injection molding. As the company looks to the future, it is poised to continue leading the way in the plastics manufacturing industry, setting new standards for excellence and reliability.

The Importance of Plastic Injection Moulding in Manufacturing

Molding Plastic Injection Mould, a leading manufacturer in the plastic injection molding industry, is proud to announce their innovative new product line designed to meet the ever-evolving needs of their customers. With over 20 years of experience in the industry, Molding Plastic Injection Mould has established itself as a trusted provider of high-quality, precision-engineered plastic injection molds for a wide range of applications.The company's commitment to quality and customer satisfaction is evident in their state-of-the-art manufacturing facility, which is equipped with the latest technology and cutting-edge machinery. This allows Molding Plastic Injection Mould to produce molds with exceptional precision and consistency, ensuring that each product meets the exact specifications of their customers.One of the key features of Molding Plastic Injection Mould's new product line is its versatility. The company offers a wide range of mold designs that can be customized to meet the unique requirements of each customer. Whether it's a simple, single-cavity mold or a complex multi-cavity mold, Molding Plastic Injection Mould has the expertise and capabilities to deliver the perfect solution.In addition to their exceptional product offerings, Molding Plastic Injection Mould also prides itself on providing outstanding customer service. The company's team of highly skilled engineers and technicians work closely with their clients to understand their needs and develop customized solutions that exceed their expectations. From the initial design phase to the final production, Molding Plastic Injection Mould is dedicated to providing a seamless and efficient experience for their customers.Furthermore, Molding Plastic Injection Mould is committed to sustainability and environmental responsibility. The company adheres to strict quality control measures to minimize waste and reduce their environmental impact. They also prioritize the use of eco-friendly materials and processes in their manufacturing operations, ensuring that their products are not only high-quality but also environmentally friendly.Another notable aspect of Molding Plastic Injection Mould's business is their competitive pricing. Despite their unwavering commitment to quality and innovation, the company offers its products at competitive prices, making them an attractive option for businesses looking for reliable and cost-effective plastic injection molds."We are thrilled to introduce our new product line to the market," said the spokesperson of Molding Plastic Injection Mould. "Our team has worked tirelessly to develop these innovative and versatile molds, and we are confident that they will exceed the expectations of our customers. We are committed to providing the highest level of quality, precision, and customer service, and we believe that our new product line reflects that commitment."With their new product line, commitment to sustainability, exceptional customer service, and competitive pricing, Molding Plastic Injection Mould continues to solidify its position as a leader in the plastic injection molding industry. As they look towards the future, the company remains dedicated to delivering cutting-edge solutions to meet the evolving needs of their customers while maintaining their unwavering commitment to quality and innovation.