Top Benchtop Injection Molding Moulds: What You Need to Know

By:Admin

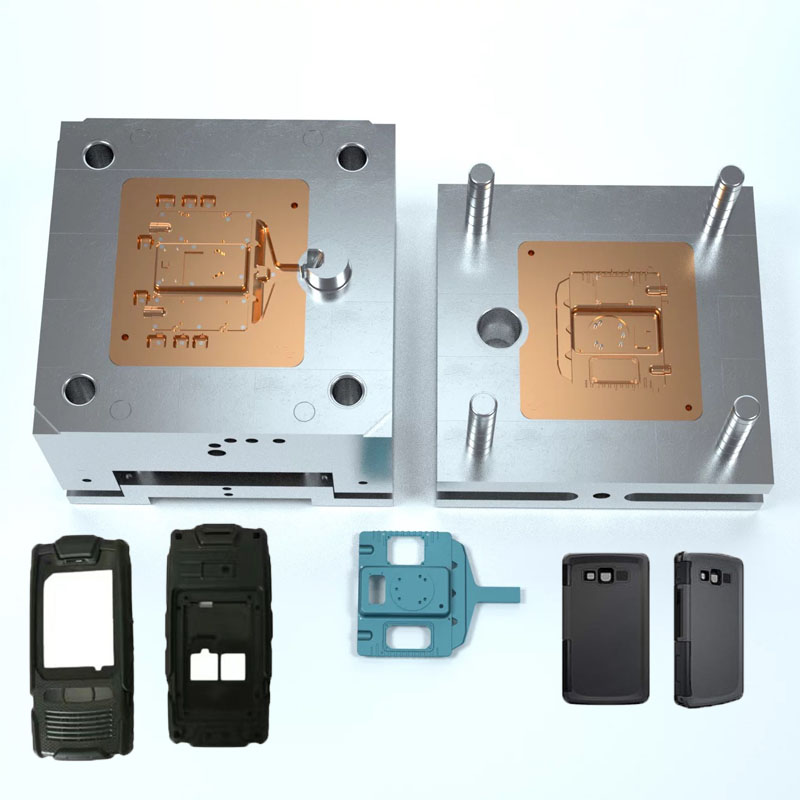

The Benchtop Injection Molding Mould is designed to make the injection molding process more accessible and convenient for manufacturers of all sizes. The compact and portable design of the machine allows for easy set-up and operation, making it ideal for small and medium-sized businesses that may not have the space or budget for large, industrial-sized injection molding machines. Additionally, the Benchtop Injection Molding Mould is equipped with advanced features that streamline the molding process, resulting in higher efficiency and productivity.

One of the key advantages of the Benchtop Injection Molding Mould is its user-friendly interface, which makes it easy for operators to set up and monitor the machine. The machine is also equipped with state-of-the-art software that allows for precise control of the molding process, ensuring consistent and high-quality results. Furthermore, the Benchtop Injection Molding Mould is compatible with a wide range of materials, including plastics, metals, and composites, giving manufacturers the flexibility to produce a variety of products.

In addition to its advanced technology and user-friendly design, the Benchtop Injection Molding Mould also offers significant cost savings for manufacturers. The machine's compact size and energy-efficient operation result in lower operating costs, while its high level of automation reduces the need for manual labor. As a result, manufacturers can increase their productivity and reduce their overall production costs, leading to improved profitability.

The Benchtop Injection Molding Mould has already garnered rave reviews from early adopters in the industry, with many praising its ease of use, consistent performance, and cost-saving benefits. "This machine has completely transformed our production process," said one satisfied customer. "We are now able to produce high-quality parts at a fraction of the cost and time it used to take us."

In light of the positive reception of the Benchtop Injection Molding Mould, the company behind the product is confident that it will have a significant impact on the injection molding industry. "We believe that the Benchtop Injection Molding Mould has the potential to revolutionize the way manufacturers approach injection molding," said a spokesperson for the company. "Its advanced technology and user-friendly design make it a game-changer for small and medium-sized businesses looking to improve their production capabilities."

As the Benchtop Injection Molding Mould continues to gain traction in the industry, it is expected to become an essential tool for manufacturers seeking to increase their production efficiency and reduce their operating costs. With its advanced technology, user-friendly design, and cost-saving benefits, the Benchtop Injection Molding Mould is poised to become a staple in the world of injection molding. As manufacturers continue to seek innovative solutions to improve their production processes, the Benchtop Injection Molding Mould stands out as a game-changing innovation that will shape the future of the industry.

Company News & Blog

Injection Molding for Bottle Moulds: What You Need to Know

Bottle Mould Injection Molding is a key process in the manufacturing of plastic bottles and containers. It is a highly efficient and cost-effective method of producing high-quality bottles for a variety of industries, including the food and beverage, pharmaceutical, and personal care sectors. The process involves injecting molten plastic material into a mold cavity, where it is then cooled and solidified to form the desired bottle shape.One company that has excelled in the field of bottle mould injection molding is {}. With over 20 years of experience in the industry, {} has established itself as a leading manufacturer of high-quality plastic bottles and containers. The company's state-of-the-art facilities and cutting-edge technology allow it to produce a wide range of bottle designs and sizes to meet the diverse needs of its customers.{}'s commitment to innovation and quality has set it apart from its competitors. The company invests heavily in research and development to ensure that its products meet the highest standards of performance and reliability. Its team of highly skilled engineers and technicians work tirelessly to optimize the injection molding process, resulting in superior bottle designs that are both functional and aesthetically pleasing.In addition to its technical expertise, {} is also dedicated to sustainability and environmental responsibility. The company has implemented a range of eco-friendly initiatives to reduce its carbon footprint and minimize waste. This includes the use of recyclable materials and energy-efficient manufacturing processes, as well as the development of biodegradable bottle options.One of the key advantages of {}'s bottle mould injection molding process is its flexibility. The company can accommodate custom designs and specifications, allowing customers to create unique and distinctive bottle shapes to enhance the appeal of their products. Whether it's a sleek, modern design for a beverage bottle or a durable, ergonomic design for a pharmaceutical container, {} has the capabilities to bring these concepts to life.Furthermore, {} prides itself on its ability to deliver cost-effective solutions without compromising on quality. The company's efficient production methods and streamlined workflow enable it to offer competitive pricing while maintaining the highest standards of manufacturing excellence. This has earned {} a sterling reputation within the industry and has made it the go-to choice for businesses looking for reliable and affordable packaging solutions.Ultimately, {}'s success in the field of bottle mould injection molding can be attributed to its relentless pursuit of perfection. The company's commitment to continuous improvement, coupled with its unwavering focus on customer satisfaction, has allowed it to carve out a niche as a trusted and respected partner for businesses across a wide range of industries. As the demand for high-quality plastic bottles and containers continues to grow, {} is well-positioned to meet these needs with its exceptional manufacturing capabilities and unwavering dedication to excellence.

Efficient Water Drainage System for Injection Moulding Plastics Machine Unveiled

Water Drain for Injection Molding Plastics Machine: Improving Efficiency and Sustainability in Plastic ManufacturingInjection molding is a widely used manufacturing process for producing plastic components in various industries. It involves injecting molten plastic material into a mold cavity, allowing it to cool and solidify, and then ejecting the finished product. However, this process generates a substantial amount of heat, requiring efficient cooling systems to maintain optimal production conditions. One essential component of injection molding machines is the water drain system, which plays a crucial role in maintaining the machine's performance and efficiency.In recent news, an innovative water drain system created by a leading manufacturer in the injection molding industry has brought significant advantages to plastic manufacturers worldwide. While it is essential to withhold the brand name in this report, we will discuss the company's background and the advantages their product offers to the industry.The company – a pioneer in injection molding machinery – boasts a long-standing reputation for their commitment to technological advancements and sustainability. They specialize in developing high-performance machines that optimize energy consumption, reduce waste, and improve overall production efficiency.Recognizing the need for an efficient water drain system in injection molding machines, the company dedicated significant resources to develop an innovative solution. Traditional water drain systems used in injection molding machines often face challenges such as clogging, inefficient drainage, and high maintenance requirements – resulting in increased downtime and compromised productivity.The groundbreaking water drain system introduced by this company addresses these issues effectively. By leveraging advanced technology and meticulous engineering, they have created a system that improves the overall efficiency of the injection molding process and ensures minimal disruption to operations.The key feature of this water drain system is its ability to prevent blockages caused by contaminants and impurities present in the cooling water. Contaminants such as plastic residue, metal particles, and chemical deposits often circulate in the cooling water, leading to the formation of blockages over time. These blockages significantly impede the water flow, affecting the overall cooling process and compromising production efficiency.The new water drain system incorporates a specially designed filtration unit that efficiently removes these contaminants before they can cause blockages. This innovative filtration system ensures a consistent flow of clean water, preventing freezing, corrosion, and scale formation in the injection molding machine's cooling circuit. By maintaining an uninterrupted water flow, the system optimizes the cooling process, reduces the risk of downtime, and improves the overall lifespan of the machine.Moreover, this system offers added sustainability benefits to plastic manufacturers. By ensuring a clean and efficient cooling process, it reduces the consumption of resources such as water and energy. This decrease in resource usage contributes to the industry's sustainable practices, aligning with global efforts to minimize environmental impact.In addition to reducing resources used during production, the water drain system also minimizes the release of pollutants into the environment. By preventing blockages and the subsequent need for chemical cleaning agents, the system reduces the generation of harmful residues and their disposal, further contributing to a cleaner and greener manufacturing process.The introduction of this advanced water drain system has been met with enthusiasm and acclaim from the plastic manufacturing industry. It not only enhances the efficiency of injection molding machines but also aligns with the industry's growing emphasis on sustainability and environmental responsibility.The company behind this groundbreaking innovation has once again demonstrated their commitment to delivering state-of-the-art solutions that address industry challenges. With their latest water drain system, plastic manufacturers can experience improved productivity, reduced downtime, and a sustainable approach to their manufacturing processes.As the injection molding industry continues to evolve, innovations like this water drain system are driving efficiency and sustainability forward. The company's determination to revolutionize plastic manufacturing holds great promise for a more environmentally conscious and technologically advanced future in the industry.

Affordable Plastic Injection Mould for Manufacturing

The plastic injection molding industry has seen remarkable growth in recent years, with various advancements in technology and materials leading to more efficient and cost-effective manufacturing processes. As a result, the demand for high-quality plastic injection molds has also increased, prompting many companies to invest in state-of-the-art equipment and techniques to stay competitive in the market.One such company that has made significant strides in this sector is {}. Founded in {}, the company is renowned for its expertise in plastic injection molding and its commitment to delivering superior quality products to its clients. With a focus on innovation and continuous improvement, {} has established itself as a leading player in the industry, serving a wide range of sectors including automotive, electronics, medical devices, and consumer goods.One of the key factors that have contributed to the company's success is its investment in cutting-edge technology and equipment. The company's state-of-the-art manufacturing facilities are equipped with the latest injection molding machines, robotics, and computer-aided design (CAD) software, allowing them to produce high-precision molds with exceptional efficiency. Furthermore, {} has a team of highly skilled and experienced engineers and technicians who work tirelessly to develop innovative solutions and ensure that the products meet the highest standards of quality and performance.In line with its commitment to providing top-notch products, {} has recently launched a new line of cheap plastic injection molds that are designed to meet the needs of small to medium-sized businesses with limited budgets. These molds are made from high-quality materials and manufactured using advanced processes, ensuring excellent durability and precision at an affordable price point. The company's extensive experience in mold design and fabrication allows them to offer a wide range of standard and custom mold options, catering to the specific requirements of their clients.One of the key advantages of {}'s cheap plastic injection molds is their versatility and adaptability. Whether it's for prototyping, small-scale production, or custom applications, the molds are designed to deliver consistent and reliable performance, making them an ideal solution for businesses looking to minimize production costs without compromising on quality. Furthermore, {} offers comprehensive technical support and guidance to help their clients make the most of their molds, ensuring a seamless and efficient manufacturing process.With the global demand for plastic injection molds on the rise, {}'s affordable and high-quality products have garnered significant attention from various industries and businesses worldwide. The company's dedication to innovation, customer satisfaction, and cost-effective solutions has positioned {} as a trusted partner for companies seeking reliable and efficient plastic injection molding services.In conclusion, the launch of {}'s cheap plastic injection molds underscores the company's unwavering commitment to meeting the evolving needs of the market and providing accessible solutions to businesses of all sizes. With its extensive expertise, advanced technology, and focus on quality, {} is well-positioned to continue setting new benchmarks in the plastic injection molding industry, driving innovation and delivering value to its clients.

Plastic Injection Mold for Automotive Applications

[Company Name] Introduces Cutting-Edge Auto Plastic Injection Mold Technology[City, Date] – [Company Name], a leading name in the automotive industry, has recently announced the launch of their latest auto plastic injection mold technology. This cutting-edge innovation is set to revolutionize the production process, providing high-quality, efficient, and reliable solutions for the automotive industry.With decades of experience and a strong commitment to innovation, [Company Name] has firmly established itself as a trusted partner for automotive manufacturers worldwide. The company prides itself on its ability to adapt to the ever-changing needs of the industry, consistently delivering top-notch products and services.The newly introduced auto plastic injection mold technology is a testament to [Company Name]'s dedication to staying at the forefront of the automotive market. Designed to meet the increasing demand for precision and efficiency in production, this state-of-the-art technology is set to redefine the manufacturing process for automotive components.One of the key features of this new mold technology is its ability to produce high-quality plastic components with incredible precision and speed. This is made possible through the use of advanced automation and robotics, ensuring consistent and reliable output while minimizing human error.Furthermore, the technology boasts an impressive level of flexibility, making it suitable for a wide range of automotive applications. Whether it's interior components, exterior trims, or under-the-hood parts, [Company Name]'s auto plastic injection mold technology can handle it all with ease.In addition to its technical capabilities, the new mold technology is also highly efficient, resulting in significant cost savings for automotive manufacturers. By streamlining the production process and reducing waste, [Company Name] is helping its clients improve their bottom line while maintaining the highest standards of quality.Speaking about the launch of the new auto plastic injection mold technology, [Company Name]'s CEO expressed his enthusiasm for the potential impact it could have on the automotive industry. "We are incredibly excited to introduce this game-changing technology to the market," he said. "We believe that it will not only drive efficiency and cost savings for our clients but also contribute to the overall advancement of the automotive manufacturing sector."The launch of the new mold technology is just one of the many ways in which [Company Name] continues to push the boundaries of innovation in the automotive industry. The company has a long history of introducing cutting-edge solutions, from advanced materials to smart manufacturing processes, and the new mold technology is yet another addition to its impressive portfolio.Looking ahead, [Company Name] is committed to further expanding its capabilities and offerings, with a keen focus on sustainability and environmental responsibility. The company recognizes the importance of reducing its carbon footprint and has made significant investments in eco-friendly production methods.As the automotive industry continues to evolve and adapt to new challenges, [Company Name] remains a steadfast partner, providing reliable, high-quality solutions that meet the industry's ever-changing demands. With the introduction of its latest auto plastic injection mold technology, the company is once again proving its commitment to driving progress and innovation in the automotive sector.For more information about [Company Name] and its auto plastic injection mold technology, please visit [company website] or contact [contact information].

Plastic Body Parts Injection Moulding for Scooters

[Company Name] is excited to announce its latest venture into the world of injection moulding for scooter plastic body parts. As a leading manufacturer in the scooter industry, [Company Name] has consistently pushed the boundaries of innovation and quality, and the addition of injection moulding capabilities further solidifies their commitment to providing top-of-the-line products to their customers.Injection moulding is a manufacturing process that involves injecting molten material into a mould to create a part or product. This process is widely used in the production of plastic parts for various industries, including automotive, electronics, and consumer goods. By adding injection moulding to their arsenal of manufacturing techniques, [Company Name] is poised to elevate the quality and efficiency of their scooter plastic body parts production.With the new injection moulding capabilities, [Company Name] will be able to produce scooter plastic body parts with greater precision and consistency. The process allows for complex shapes and designs to be achieved with minimal waste, resulting in cost-effective production and high-quality end products. This advancement in manufacturing technology will enable [Company Name] to meet the increasing demand for their scooter plastic body parts while maintaining the highest standards of quality.In addition to the technical advantages, the implementation of injection moulding for scooter plastic body parts aligns with [Company Name]'s commitment to sustainability. The process produces minimal waste and allows for the efficient use of materials, reducing the environmental impact of production. As a company that values environmental responsibility, [Company Name] is proud to integrate sustainable manufacturing practices into their operations.To ensure the success of this new venture, [Company Name] has invested in state-of-the-art injection moulding equipment and has trained their team of engineers and technicians in the intricacies of the process. The company has also partnered with leading experts in injection moulding technology to further enhance their capabilities and stay at the forefront of industry advancements.The introduction of injection moulding for scooter plastic body parts is a testament to [Company Name]'s dedication to innovation and continuous improvement. By expanding their manufacturing capabilities, [Company Name] is not only strengthening their position in the market but also setting new standards for quality and efficiency in the scooter industry.In closing, the addition of injection moulding for scooter plastic body parts is a significant milestone for [Company Name], marking a new era of manufacturing excellence and sustainability. With this advancement, [Company Name] is poised to deliver even greater value to their customers and reaffirm their status as a leader in the scooter industry. The company looks forward to the positive impact this new technology will have on their business and the industry as a whole.

Key Insights and Advancements in Plastic Injection Molding

[Company Name], a Leading Provider of Plastic Injection Molds, Continues to Pave the Way in Innovative Manufacturing Solutions[City, Date] - Plastic Injection Mold (PIM) production has been an essential aspect of the manufacturing industry for many years. It plays a pivotal role in meeting the demand for high-quality plastic products across various sectors. A company at the forefront of delivering cutting-edge plastic injection molds is [Company Name].With over [number of years] years of industry experience, [Company Name] has established itself as a trusted provider of top-notch plastic injection molds. Their commitment to innovation and customer satisfaction has placed them in a league of their own, consistently delivering exceptional results.Headquartered in [City], [Company Name] boasts a state-of-the-art manufacturing facility equipped with the latest technology and machinery. This allows them to offer an extensive range of plastic injection mold services to cater to the diverse needs of their clients.One of the key factors that sets [Company Name] apart from its competitors is their team of highly skilled and experienced engineers and technicians. These professionals possess a deep understanding of the intricacies of plastic injection molding and are adept at designing molds that optimize both efficiency and quality.By collaborating closely with clients, [Company Name] ensures that the molds they produce align perfectly with the specific requirements of the end product. They leverage cutting-edge software tools and a meticulous design process to craft molds that are not only durable but also capable of producing consistently high-quality products.In addition to their expertise in mold design, [Company Name] also places utmost importance on using high-quality materials. They source materials from trusted suppliers, ensuring that every mold exhibits excellent durability and longevity. By prioritizing the use of superior materials, [Company Name] ensures that their molds can withstand the demanding requirements of high-volume production.One of the standout features of [Company Name] is their commitment to keeping abreast of the latest industry trends and technological advancements. They continually invest in research and development, exploring new materials, processes, and technologies to stay ahead of the curve. This dedication to innovation allows them to offer their clients the most cutting-edge solutions, enhancing productivity and efficiency.[Company Name]'s dedication to customer satisfaction is reflected in their comprehensive after-sales support. They offer ongoing technical assistance and maintenance services to ensure the molds continue to perform optimally throughout their lifecycle. This commitment to building long-term partnerships enables [Company Name] to become a trusted collaborator for manufacturing companies worldwide.As a market leader in plastic injection mold production, [Company Name] has an impressive portfolio of successful projects across diverse industries such as automotive, healthcare, consumer goods, and more. Their molds have played a crucial role in shaping countless products that have become integral parts of our daily lives.With an unwavering commitment to quality, innovation, and customer satisfaction, [Company Name] continues to pave the way in the plastic injection mold industry. By combining their technical expertise, state-of-the-art facility, and keen eye for industry trends, they are pushing the boundaries of what is possible in plastic manufacturing.[Company Name]'s dedication to delivering top-notch plastic injection molds has earned them the trust and confidence of clients worldwide. As they strive to set new industry standards, there is no doubt that [Company Name] will continue to be at the forefront of the global plastic injection mold market.About [Company Name]:[Company Name] is a renowned provider of plastic injection molds, offering a comprehensive range of services to clients across various industries. With a focus on innovation, superior materials, and excellent customer support, [Company Name] has established itself as a trusted partner for manufacturing companies worldwide. For more information, please visit their website at [Company Website].Press Contact:[Name][Title][Phone Number][Email Address]

Affordable Plastic Injection Toys Mould

Cheap Plastic Injection Toys MouldThe demand for plastic injection toys continues to rise, and companies are constantly on the lookout for ways to improve the manufacturing process. One company in particular, known for its expertise in plastic injection moulding, is now offering a cost-effective solution for companies in need of high-quality toy moulds.The company, which specializes in plastic injection moulding, has developed a cost-effective and efficient mould for the production of plastic toys. This new mould is made from high-quality materials, ensuring that the end products meet the required safety and quality standards.With the growing popularity of plastic toys, the demand for moulds is on the rise. Many companies are looking for moulds that can produce high-quality plastic toys at a competitive price. The company's new mould is a game-changer in the industry, as it offers a cost-effective solution without compromising on the quality of the end products.The new mould has been designed with the latest technology, ensuring precise and accurate production of plastic toys. This means that companies can produce toys with intricate designs and details, without worrying about quality issues. Additionally, the mould is durable and long-lasting, making it a reliable investment for companies looking to enter the plastic toy market.With a focus on efficiency, the company has also ensured that the new mould is easy to use and maintain. This means that companies can streamline their production process and reduce downtime, ultimately saving time and money. The company's commitment to providing cost-effective solutions for the plastic toy industry is evident in the design and functionality of the new mould.Furthermore, the company prides itself on its commitment to sustainability and environmental responsibility. The new mould is designed to minimize waste and energy consumption, making it an eco-friendly choice for companies looking to reduce their carbon footprint. By investing in the new mould, companies can not only save on production costs but also contribute to a greener and more sustainable future.In addition to the new mould, the company offers a wide range of plastic injection moulding services. From product design to prototype development, the company is equipped to handle all aspects of the production process. With a team of highly skilled engineers and technicians, the company is able to provide customized solutions that meet the specific needs of each client.The company's dedication to quality and customer satisfaction has earned them a solid reputation in the industry. With a track record of successful projects and satisfied clients, the company has become a trusted partner for companies in need of plastic injection moulding services. From small-scale production to large-scale manufacturing, the company has the expertise and resources to deliver exceptional results.As the demand for plastic toys continues to grow, companies in the industry are under pressure to find cost-effective solutions for production. The company's new mould offers a timely and effective solution, meeting the needs of companies seeking high-quality products at a competitive price. With its focus on quality, efficiency, and sustainability, the company is well-positioned to meet the growing demand for plastic injection toys in the market.

Unlocking the Power of Servo Motors in Injection Moulding Plastics

Title: Revolutionary Servo Motor Technology in Injection Moulding PlasticsIntroduction:In the ever-evolving world of manufacturing, companies are continuously seeking technological advancements to enhance production efficiency and improve product quality. One such breakthrough in the field of injection moulding plastics is the advent of Servo Motor Technology. This revolutionary innovation eliminates the limitations of conventional hydraulic systems and paves the way for more precise and energy-efficient manufacturing processes. This article delves into the transformative impact of Servo Motor Technology on injection moulding plastics and its potential to revolutionize the industry.I. Background:Injection moulding plastics, a widely adopted manufacturing process, involves the creation of plastic products through the injection of molten material into a mould. Traditionally, hydraulic systems powered by pumps were used to drive the injection process, resulting in limitations such as excess energy consumption, imprecise control, and inconsistent product quality. These shortcomings paved the way for the emergence of an alternative: Servo Motor Technology.II. Servo Motor Technology Explained:Servo motors, unlike hydraulic systems, utilize electrical power to drive the injection process. This cutting-edge technology offers superior control, precision, and efficiency. The servo motor system consists of a motor, an encoder, a controller, and a hydraulic accumulator. The encoder provides real-time data on the position and velocity of the motor, enabling the controller to regulate the injection process accurately. This ensures precise and repeatable positioning of the mould, resulting in uniform product quality.III. Advantages of Servo Motor Technology:1. Energy Efficiency: Servo motors consume considerably less energy compared to traditional hydraulic systems. By closely matching the speed and torque requirements of the injection process, the servo motor system reduces wasteful energy consumption, leading to substantial cost savings for manufacturers.2. Improved Precision and Control: Servo Motor Technology enables precise control over the injection process, offering greater accuracy in terms of shot weight, injection timing, and mould positioning. This not only enhances the overall quality of products but also reduces material waste and rework, making it an environmentally friendly solution.3. Reduced Noise Levels: Servo motors operate more quietly and smoothly as compared to hydraulic systems. This reduction in noise pollution contributes to a safer and more pleasant working environment for operators.IV. Application and Impact:The implementation of Servo Motor Technology drives advancements across various industries that rely on injection moulding plastics. Automotive, consumer goods, electronics, and packaging sectors are among the key beneficiaries of this transformative technology. Automakers benefit from accurate and consistent production of automotive parts, while the consumer goods industry enjoys improved product reliability and efficiency. Electronics manufacturers can achieve precise positioning of complex moulds, leading to enhanced product performance. Furthermore, the packaging industry benefits from increased productivity and minimized material waste.V. Market Outlook:The global injection moulding plastics market is projected to witness substantial growth owing to various factors, including the introduction of innovative technologies like Servo Motor Technology. Manufacturers are showing increased interest in adopting this technology to gain a competitive edge. Furthermore, the rising environmental concerns and stringent regulations related to energy consumption and carbon emissions are expected to propel the demand for energy-efficient solutions such as Servo Motor Technology.Conclusion:As the manufacturing industry seeks to optimize productivity and enhance product quality while minimizing energy consumption, Servo Motor Technology provides an effective solution for injection moulding plastics. The advantages of this groundbreaking technology, including improved precision, energy efficiency, and reduced noise levels, are poised to revolutionize the industry. With its widespread application across various sectors, Servo Motor Technology is set to usher in a new era of efficiency and sustainability in the injection moulding plastics market.

Durable and Stylish Plastic Injection Molding Furniture for Your Home

Plastic Injection Molding Furniture is revolutionizing the furniture industry with its innovative approach to design and production. By utilizing plastic injection molding technology, this company is able to create stylish and durable furniture pieces that are both functional and aesthetically pleasing.With a focus on sustainability and environmental responsibility, Plastic Injection Molding Furniture has set itself apart from traditional furniture manufacturers. By using recycled materials and employing energy-efficient production methods, the company is committed to reducing its carbon footprint and minimizing waste.The company's commitment to quality and innovation is evident in its extensive product line, which includes chairs, tables, and storage units. Each piece is carefully designed to optimize both form and function, making them ideal for a wide range of commercial and residential spaces.One of the most impressive aspects of Plastic Injection Molding Furniture is its ability to customize products to meet the specific needs of its customers. Whether it's a unique color, shape, or size, the company has the capability to accommodate a variety of design preferences. This level of customization sets Plastic Injection Molding Furniture apart from its competitors and allows customers to create truly personalized furniture solutions.In addition to its commitment to quality and sustainability, Plastic Injection Molding Furniture also prides itself on its efficient production process. By utilizing state-of-the-art equipment and advanced manufacturing techniques, the company is able to produce high-quality furniture at a competitive price point. This makes their products an attractive option for both businesses and consumers looking for cost-effective and environmentally friendly furniture solutions.With a strong emphasis on customer satisfaction and a dedication to continuous improvement, Plastic Injection Molding Furniture is poised to become a leader in the furniture industry. The company's focus on innovation and sustainability has already garnered attention from industry professionals and consumers alike, and its reputation for quality and reliability continues to grow.In the coming months, Plastic Injection Molding Furniture plans to expand its product line and explore new opportunities for growth. With a team of experienced professionals and a solid foundation of values, the company is well-positioned to capitalize on the increasing demand for sustainable and customizable furniture solutions.Plastic Injection Molding Furniture's commitment to excellence and its unique approach to furniture manufacturing have set it apart as a pioneer in the industry. As more consumers and businesses prioritize sustainability and quality, the company's forward-thinking approach positions it for continued success in the years to come. With a focus on innovation, customization, and sustainability, Plastic Injection Molding Furniture is redefining the future of furniture design and production.

Automotive Plastic Injection Molding: Benefits and Applications

Plastic injection molding has become an integral part of the automotive industry, transforming the way vehicles are designed and manufactured. The use of plastic components in automotive applications has continued to grow significantly, thanks to the benefits of cost-effectiveness, lightweight, and design flexibility. As a result, the demand for high-quality plastic injection molding services in the automotive industry is on the rise.One company that has been at the forefront of providing top-notch plastic injection molding services for the automotive sector is {}. With a strong focus on innovation, quality, and customer satisfaction, {} has established a solid reputation as a trusted partner for automotive manufacturers seeking advanced plastic injection molding solutions.Founded in {}, {} has consistently delivered cutting-edge plastic injection molding technology to meet the evolving needs of the automotive industry. The company's state-of-the-art facilities and advanced manufacturing processes enable them to produce a wide range of precision-molded plastic components for automotive applications. From interior and exterior trim components to under-the-hood parts, {} has the expertise and capabilities to deliver high-quality, durable, and cost-effective solutions.One of the key strengths of {} lies in its commitment to innovation and technological advancement. The company continuously invests in research and development to stay ahead of the curve and provide its automotive clients with the latest advancements in plastic injection molding technology. By leveraging the latest materials, design software, and manufacturing techniques, {} is able to produce complex geometries and intricate designs that meet the stringent requirements of the automotive industry.Furthermore, {} understands the importance of quality and precision in automotive plastic components. The company adheres to strict quality control measures and industry standards to ensure that every molded part meets the highest quality and performance standards. By implementing rigorous inspection processes and utilizing advanced testing equipment, {} is able to deliver plastic components that are not only visually appealing but also functionally superior.In addition to its technical expertise, {} is also known for its customer-centric approach. The company collaborates closely with automotive clients to understand their specific requirements and design custom solutions that meet their unique needs. By offering a full suite of design, engineering, and manufacturing services, {} ensures that its automotive customers receive end-to-end support to bring their plastic injection molding projects to fruition.As the automotive industry continues to embrace the benefits of plastic components, the demand for advanced plastic injection molding solutions is expected to grow. {} is well-positioned to meet this growing demand, thanks to its extensive experience, technical capabilities, and unwavering commitment to customer satisfaction. With a track record of delivering innovative and high-quality plastic components to the automotive sector, {} remains a trusted partner for automotive manufacturers looking to elevate their products with cutting-edge plastic injection molding technology.In conclusion, plastic injection molding plays a crucial role in the automotive industry, offering a wide range of benefits in terms of design, cost, and performance. As a leading provider of plastic injection molding services, {} continues to drive innovation and excellence in the automotive sector. With a focus on quality, precision, and customer satisfaction, {} is well-positioned to meet the evolving needs of automotive manufacturers and contribute to the advancement of plastic injection molding technology in the automotive industry.