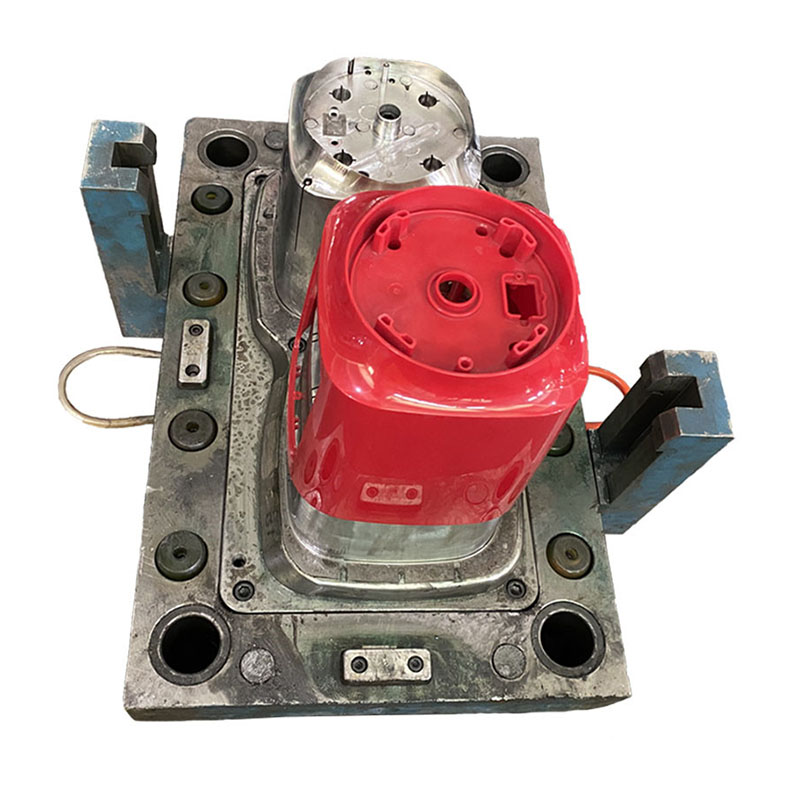

Plastic Toy Manufactured Using Mold Injection Process

By:Admin

The company, which has been in operation for over 20 years, prides itself on its commitment to safety and quality control. It has built a reputation for producing toys that are not only fun and entertaining but also meet stringent safety standards. However, this recent revelation has raised concerns about the company's manufacturing processes and has prompted the need for a thorough investigation.

The mold in question was used to inject plastic into the production of a popular toy that has garnered a large following among children. Upon inspection, traces of mold were found inside the mold, which raised alarms about the potential health risks associated with the toys. This has sparked fears among parents and caregivers who have purchased the toys for their children, as mold exposure can cause a range of health issues, including respiratory problems and allergic reactions.

In response to the discovery, the company issued a statement assuring the public that they are taking the matter seriously and have implemented immediate measures to address the issue. The affected mold has been removed from production, and thorough inspections are being conducted on all other molds to ensure that similar contamination does not exist elsewhere in the manufacturing process.

Furthermore, the company has launched a product recall for the affected toys, urging consumers to return them for a full refund or exchange. The company has also offered to cover any medical expenses for individuals who may have been affected by the mold exposure. These swift actions are aimed at mitigating the potential harm caused by the contaminated toys and maintaining the company's commitment to safety and transparency.

In addition to the product recall, the company has initiated a full-scale review of its manufacturing processes and quality control measures. This includes conducting thorough inspections of all molds, implementing stricter cleanliness protocols, and enhancing staff training on mold prevention. These measures are designed to prevent similar incidents from occurring in the future and to rebuild consumer trust in the company's products.

Despite this setback, [Company Name] remains dedicated to upholding its reputation for producing safe and high-quality toys. The company has been proactive in addressing the issue and has emphasized its commitment to transparency and accountability. By taking swift and decisive action, the company aims to reassure consumers that their safety is a top priority and that steps are being taken to prevent similar incidents from happening again.

Moving forward, [Company Name] is focused on regaining the trust of its customers and ensuring that its manufacturing processes meet the highest standards of safety and quality. The company has expressed its gratitude to the public for their continued support and understanding as it works to resolve this issue.

In conclusion, [Company Name] is addressing the mold contamination issue with the utmost seriousness and has taken swift action to rectify the situation. By initiating a product recall, conducting thorough inspections, and implementing stricter quality control measures, the company is demonstrating its commitment to ensuring the safety of its products. As the investigation continues, [Company Name] remains dedicated to upholding its reputation for producing safe and reliable toys for children to enjoy.

Company News & Blog

Plastic Injection Mould for Flower Pot Production

[Company Name] Introduces New Flower Pot Plastic Injection Mould to Enhance Product Quality[City, State] – [Date] – [Company Name], a leading manufacturer of plastic injection moulds, has announced the launch of its latest product, the Flower Pot Plastic Injection Mould. This new mould is designed to significantly improve the quality and consistency of flower pot production, offering customers a cost-effective solution for their manufacturing needs.The Flower Pot Plastic Injection Mould is the result of months of research and development, with [Company Name]’s team of engineers and designers working tirelessly to create a mould that meets the highest industry standards. The mould boasts a durable and reliable construction, ensuring that it can withstand the rigors of high-volume production while maintaining its precision and accuracy.One of the key features of the Flower Pot Plastic Injection Mould is its innovative design, which allows for the seamless production of flower pots with intricate details and smooth finishes. This level of precision is essential for companies looking to set themselves apart in the competitive flower pot market, and [Company Name] is proud to offer a mould that can help them achieve this goal.In addition to its exceptional quality, the Flower Pot Plastic Injection Mould is also designed with ease of use and maintenance in mind. Its user-friendly interface and simple operation make it accessible to production teams of all skill levels, while its robust build ensures minimal downtime and maintenance requirements. As a result, customers can expect increased efficiency and productivity when using this mould in their manufacturing processes.“We are thrilled to introduce the Flower Pot Plastic Injection Mould to the market,” said [Spokesperson], [Title] at [Company Name]. “We believe that this mould will be a game-changer for companies in the flower pot industry, offering them a reliable and high-quality solution for their production needs. Our team has put a lot of effort into perfecting this mould, and we are confident that it will deliver exceptional results for our customers.”The release of the Flower Pot Plastic Injection Mould underscores [Company Name]’s commitment to innovation and customer satisfaction. With a proven track record of delivering top-notch moulds and excellent customer service, the company has earned a strong reputation in the industry and is trusted by businesses worldwide.“We take great pride in our ability to provide advanced moulding solutions that address the unique needs of our customers,” added [Spokesperson]. “The Flower Pot Plastic Injection Mould is a testament to our dedication to excellence, and we are excited to see the positive impact it will have on our customers’ operations.”As [Company Name] continues to expand its product offerings and strengthen its position as a leading mould manufacturer, the introduction of the Flower Pot Plastic Injection Mould is a significant milestone. With its superior quality, efficiency, and user-friendly design, this mould is poised to become a sought-after solution for companies in the flower pot industry and beyond.For more information about the Flower Pot Plastic Injection Mould and other products offered by [Company Name], please visit [Website] or contact [Contact Information].About [Company Name]:[Company Name] is a renowned manufacturer of high-quality plastic injection moulds, serving a diverse range of industries with innovative and reliable solutions. With a focus on excellence and customer satisfaction, the company has established itself as a trusted partner for businesses seeking top-tier moulding products and services.

Discover the Advantages of Plastic Trash Can Injection Molding for Efficient Waste Management Solutions

Plastic Trash Can Injection Molding: Revolutionizing Waste ManagementIn today's fast-paced and consumer-driven world, the issue of waste management has become a pressing concern. With the ever-increasing production and consumption of products, the need for effective waste disposal solutions has never been more crucial. One company at the forefront of this revolution is a leading plastic injection molding manufacturer, recognized for its innovation and commitment to sustainability and environmental conservation.Plastic trash can injection molding, a manufacturing process that involves injecting molten plastic into a mold, has proven to be a game-changer in the waste management industry. The company, renowned for its expertise in this domain, has revolutionized the design and production of plastic trash cans, offering superior quality, durability, and cost-effectiveness.As waste management becomes an increasing challenge, the need for durable and long-lasting trash cans has intensified. These plastic trash cans, manufactured using advanced injection molding techniques, are resistant to cracking, fading, and extreme weather conditions. By ensuring their products stand the test of time, the company has significantly reduced the need for frequent replacements, saving both resources and costs.Furthermore, the company has always prioritized sustainability in their manufacturing processes. With a deep commitment to environmental conservation, they use recyclable plastics in the production of their trash cans. By promoting the use of recycled materials, they contribute to the reduction of single-use plastics in landfills and the overall preservation of our planet.The injection molding technology employed by the company allows for the production of trash cans with intricate designs, diverse sizes, and varying capacities. Whether it is a small waste bin for personal use or a large container for commercial purposes, these plastic trash cans are versatile and cater to a wide range of needs. The company understands the importance of customization and offers their clients the flexibility to design trash cans that align with their specific requirements.Moreover, the injection molding process ensures consistent quality and precision. Each trash can is precisely molded, leaving no room for imperfections or inaccuracies. By eliminating the risk of defective products, the company has gained a reputation for delivering excellence and customer satisfaction.With a strong commitment to social responsibility, the company actively collaborates with local authorities and waste management organizations to devise sustainable waste management solutions. By aligning their goals with those of the community, they actively contribute to the development of efficient waste disposal systems.The plastic trash cans produced through injection molding are not only durable and visually appealing but also contribute to the cleanliness and tidiness of public spaces and households. With their innovative designs and color options, the company's trash cans add a touch of elegance to urban landscapes while serving their primary purpose of waste management.In addition to producing plastic trash cans, the company also offers a range of accessories and complementary products, further enhancing waste management efficiency. These include trash can liners, recycling bins, and waste segregation systems, all designed to facilitate the sorting and disposal of various types of waste.In conclusion, plastic trash can injection molding has redefined waste management, providing durable, customizable, and sustainable solutions. The company, recognized for its expertise in this manufacturing process, has revolutionized the industry by delivering high-quality products, promoting environmental conservation, and actively supporting sustainable waste management strategies. Through their commitment to excellence and innovation, they are leading the way towards a cleaner and more sustainable future.

High-Quality Plastic Injection Mould for Used Chair

{Company Name} Unveils New State-of-the-Art Used Chair Plastic Injection Mould{City, Date}: {Company Name}, a leading provider of innovative plastic injection moulding solutions, has recently announced the release of their latest product – a high-quality used chair plastic injection mould. The company’s dedication to providing top-notch moulding solutions to their clients makes this latest addition a significant milestone in their journey.{Company Name} has earned a reputation for excellence in the industry, delivering cutting-edge products and services to a wide range of customers. Their commitment to quality, efficiency, and innovation has made them a trusted partner for businesses seeking reliable moulding solutions.The new used chair plastic injection mould is a testament to {Company Name}’s dedication to meeting the evolving needs of their clients. This mould is designed to deliver superior performance and durability, providing businesses with a cost-effective solution for their chair manufacturing needs. With a focus on precision engineering and advanced technology, {Company Name} ensures that their moulds meet the highest industry standards.The addition of the used chair plastic injection mould to {Company Name}’s product lineup is expected to have a significant impact on the industry. As the demand for high-quality, cost-effective moulding solutions continues to grow, businesses can rely on {Company Name} to provide them with the tools they need to stay competitive in the market.“We are thrilled to introduce our new used chair plastic injection mould to the market,” said {Spokesperson Name}, {Title} at {Company Name}. “This product is a result of our unwavering commitment to innovation and excellence. We believe that it will make a significant difference for businesses looking for reliable moulding solutions.”The used chair plastic injection mould is designed to be versatile, allowing businesses to produce a wide range of chair designs with ease. Its robust construction and advanced features make it well-suited for high-volume manufacturing, ensuring that businesses can meet their production targets without compromising on quality.{Company Name}’s dedication to customer satisfaction is evident in the design and performance of their products. With the addition of the used chair plastic injection mould to their portfolio, they aim to further strengthen their position as a leader in the moulding industry.As a company that places a strong emphasis on sustainability, {Company Name} is committed to reducing waste and minimizing environmental impact. The new used chair plastic injection mould reflects this commitment, as it is designed to optimize material usage and minimize energy consumption, thereby helping businesses reduce their carbon footprint.In addition to their cutting-edge products, {Company Name} also offers comprehensive support and services to their clients. Their team of experts is dedicated to assisting businesses in optimizing their manufacturing processes, ensuring that they get the most out of their moulding solutions.With the introduction of the used chair plastic injection mould, {Company Name} is poised to set new benchmarks in the industry. Their relentless pursuit of excellence and innovation continues to drive them forward, making them a preferred partner for businesses seeking reliable and efficient moulding solutions.About {Company Name}:{Company Name} is a leading provider of plastic injection moulding solutions, serving a diverse range of clients across various industries. With a focus on quality, efficiency, and innovation, {Company Name} has established itself as a trusted partner for businesses seeking reliable moulding solutions.For media inquiries:Contact: {Contact Information}Website: {Company Website}

Ultimate Guide to Aluminum Injection Molding: Everything You Need to Know

Injection Molding Aluminum, a cutting-edge manufacturing process, has been making waves in the industry due to its remarkable efficiency and precision in producing high-quality parts. This innovative technology has been adopted by leading companies such as {}, a renowned manufacturer in the automotive and aerospace sectors.Established in 1995, {} has been at the forefront of delivering advanced engineering solutions to its global clientele. Specializing in the production of components for industries such as automotive, aerospace, defense, and medical, the company has built a solid reputation for its commitment to excellence and continuous innovation.The adoption of Injection Molding Aluminum technology has further solidified {}'s position as a leader in the industry. This state-of-the-art process has enabled the company to offer its customers an advanced manufacturing solution that delivers unparalleled precision, consistency, and cost-effectiveness.Injection Molding Aluminum is a highly efficient manufacturing process that involves injecting molten aluminum into a mold cavity at high pressure. This results in the production of complex and intricate parts with exceptional accuracy and surface finish. The process is ideal for producing lightweight and durable components, making it a perfect fit for industries such as automotive and aerospace where materials with superior strength-to-weight ratios are essential.By leveraging Injection Molding Aluminum, {} has been able to meet the increasing demand for lightweight and high-strength parts in the automotive and aerospace sectors. The technology has enabled the company to manufacture components that not only meet but exceed the stringent performance and quality standards of these industries.One of the key advantages of Injection Molding Aluminum is its ability to produce parts with minimal material waste. This results in a more sustainable and environmentally friendly manufacturing process, aligning with {}'s commitment to responsible and eco-friendly production practices. With a focus on reducing the environmental impact of its operations, the company continues to invest in cutting-edge technologies that promote sustainability and resource efficiency.Furthermore, Injection Molding Aluminum offers a shorter production cycle and reduced lead times, allowing {} to improve its operational efficiency and meet tight project deadlines. This has been particularly advantageous for the company's clients in the automotive and aerospace sectors, where time-to-market is crucial for staying ahead of the competition.In addition to its technological advancements, {} is also dedicated to maintaining the highest quality standards in all aspects of its operations. The company has earned various certifications and accreditations, including ISO 9001 and AS9100, demonstrating its commitment to delivering superior quality products and services to its customers.With Injection Molding Aluminum, {} has expanded its capabilities and enhanced its ability to provide innovative solutions to its diverse range of clients. From intricate components for luxury automobiles to critical parts for aerospace applications, the company has demonstrated its versatility and expertise in meeting the unique requirements of each industry it serves.Looking ahead, {} remains committed to pushing the boundaries of innovation and excellence in manufacturing. The company continues to invest in research and development, seeking out new technologies and processes that will further enhance its capabilities and drive the next generation of manufacturing solutions.As a leading expert in the automotive and aerospace manufacturing sectors, {} is well-positioned to continue its growth and success, delivering exceptional products and services that meet the evolving needs of the industry. With its adoption of Injection Molding Aluminum, the company has once again demonstrated its commitment to staying at the forefront of manufacturing innovation and leading the way in delivering advanced engineering solutions to its global clients.

Custom Injection Molding and Part Injection Mould in China

China Custom Injection Molding and Part Injection Mould, a major player in the injection molding industry, has been making waves in the global market with its high-quality products and advanced technology. The company, based in China, has built a strong reputation for providing custom injection molding solutions to a wide range of industries including automotive, medical, consumer goods, and electronics.With a commitment to innovation and customer satisfaction, China Custom Injection Molding and Part Injection Mould has been at the forefront of developing cutting-edge injection molding technology. The company’s state-of-the-art manufacturing facilities are equipped with the latest machinery and tools to ensure precision and efficiency in producing high-quality injection molded parts.One of the key factors that sets China Custom Injection Molding and Part Injection Mould apart from its competitors is its dedication to meeting the specific needs of its clients. The company’s team of experienced engineers and designers work closely with customers to understand their unique requirements and provide tailored solutions to meet their exact specifications.In addition to custom injection molding, China Custom Injection Molding and Part Injection Mould also specializes in part injection mold manufacturing. The company’s expertise in mold design and production ensures that customers receive the best possible solutions for their injection molding needs. With a focus on precision engineering and quality control, China Custom Injection Molding and Part Injection Mould consistently delivers top-notch injection molded parts to its global clientele.The company’s commitment to quality is further evident in its adherence to strict manufacturing standards and practices. China Custom Injection Molding and Part Injection Mould is certified to ISO 9001, demonstrating its dedication to maintaining the highest levels of quality and reliability in its products and services.China Custom Injection Molding and Part Injection Mould’s dedication to excellence has earned it a solid reputation in the global market. By continually investing in research and development, the company stays ahead of the curve in terms of technological advancements and industry trends. This forward-thinking approach allows China Custom Injection Molding and Part Injection Mould to remain a trusted partner for clients seeking high-quality injection molding solutions.As the demand for custom injection molding continues to grow, China Custom Injection Molding and Part Injection Mould is well-positioned to capitalize on this trend. The company’s proven track record, commitment to quality, and dedication to customer satisfaction set it apart as a leader in the injection molding industry. With a focus on innovation and excellence, China Custom Injection Molding and Part Injection Mould is poised to continue making significant contributions to the global manufacturing sector.In conclusion, China Custom Injection Molding and Part Injection Mould’s dedication to providing high-quality custom injection molding solutions has solidified its position as a leader in the industry. With a focus on innovation, precision, and customer satisfaction, the company continues to set the standard for excellence in injection molding. As the demand for custom injection molding solutions continues to rise, China Custom Injection Molding and Part Injection Mould is well-prepared to meet the needs of its global clientele and maintain its reputation as a trusted provider of high-quality injection molded parts.

Exploring the Latest Trends in Container Cover Mould and Food Container Box Mould in China

Title: Chinese Mold Company Achieves Breakthrough with Container Cover and Food Box MoldsIntroduction:In a groundbreaking development, a prominent Chinese mold manufacturer has successfully designed and manufactured innovative Container Cover Mould and Food Container Box Moulds. With an unwavering commitment to quality and a focus on meeting the ever-evolving demands of the market, this company has proven itself as a leader in the manufacturing industry. Deploying state-of-the-art technology and leveraging their expertise, the company has designed molds that guarantee durability, functionality, and efficiency. This achievement demonstrates China's growing influence in the global manufacturing sector.A Diverse Range of Container Cover Moulds:The Container Cover Mould series developed by the company offers a versatile solution for the packaging industry. These molds are capable of producing container covers of various sizes and designs, catering to the specific needs of different industries. With a focus on durability and longevity, the molds are crafted using high-quality materials that ensure resistance against wear and tear.One of the major advantages of these Container Cover Moulds is their compatibility with different manufacturing processes, such as injection molding and blow molding. This adaptability makes these molds highly sought-after in industries ranging from food packaging to pharmaceuticals. By providing a reliable solution for manufacturers, the company aims to enhance the efficiency of production and reduce costs.Cutting-Edge Food Container Box Moulds:Recognizing the growing need for sustainable and functional food packaging solutions, the Chinese mold company has developed Food Container Box Moulds that have gained immense popularity in the market. These molds are specifically designed to meet the stringent requirements of the food industry.The Food Container Box Mould series offers a wide range of design options, providing manufacturers with the flexibility to create custom-made containers for different purposes. These molds are manufactured using food-grade materials that comply with international safety standards. Furthermore, the molds are designed to ensure leak-proof and airtight seals, enhancing the freshness and shelf life of the stored food products.The company's Food Container Box Moulds also prioritize eco-friendliness. By incorporating a sustainable approach, these molds reduce material waste and promote the use of recyclable materials. In an era where environmental consciousness has become a priority, these molds serve as a testament to China's commitment to sustainable development.Company Commitment to Excellence:Established with a vision to revolutionize the mold manufacturing industry, the Chinese mold company has consistently strived for excellence. With extensive expertise and advanced technology, the company integrates research, development, and manufacturing processes to meet the dynamic needs of the global market.The company's success can be attributed to its team of highly skilled professionals who possess vast experience in mold design and production. Additionally, the company invests significantly in research and development, continually exploring innovative solutions to ensure its molds remain at the forefront of the industry.Conclusion:China's growing influence in the manufacturing sector is exemplified by the exceptional Container Cover Mould and Food Container Box Mould series developed by a prominent mold manufacturer. By combining durability, functionality, and innovation, these molds offer a comprehensive solution for various industries, including food packaging, pharmaceuticals, and more. With a commitment to excellence and sustainability, the Chinese mold company has cemented its position as a leading global provider of high-quality molds, propelling China to the forefront of the mold manufacturing industry.

Discover the Latest Prices of Silicon Carbide Buckets and Silicone Ice Cube Buckets in China

China Plans to Increase Production of Silicon Carbide Bucket and Silicone Ice Cube Bucket to Meet Growing DemandChina, a global leader in manufacturing and technological advancements, is set to boost its production of silicon carbide and silicone ice cube buckets to cater to the increasing demand in both domestic and international markets.Silicon carbide, a synthetic material made from a combination of silicon and carbon, possesses exceptional properties that make it highly desirable for a wide range of industrial applications. Known for its hardness, durability, and thermal conductivity, silicon carbide is extensively used in manufacturing buckets for various purposes, including industrial processes, construction, and even for household use. With its ability to withstand extreme temperatures and resist corrosion, silicon carbide buckets have become popular for their longevity and reliability.Similarly, silicone ice cube buckets have gained popularity due to their flexibility, non-stick properties, and ability to withstand extreme temperatures. Made from silicone, a synthetic rubber-like material, these buckets are used for freezing water and other liquids to form ice cubes. Silicone ice cube buckets have emerged as a convenient and hygienic alternative to traditional ice trays, making them a sought-after commodity in households, restaurants, and bars.Recognizing the expanding demand for silicon carbide and silicone ice cube buckets, Chinese manufacturers are taking significant steps to increase their production capacity. The surge in demand can be attributed to the growing industrial sector in China, as well as the rising popularity of silicone-based products globally. China's robust manufacturing ecosystem and technological expertise have made it an ideal location for the production of these buckets, enabling faster market penetration and competitive pricing.Several leading Chinese manufacturers, supported by the latest technologies and state-of-the-art facilities, are poised to become key players in the silicon carbide and silicone ice cube bucket market. These companies aim to leverage their expertise in material science and engineering to develop innovative products that meet the evolving needs of consumers.One such company, with its strong commitment to quality and innovation, is a prominent player in the industry. With a vision to offer superior silicon carbide and silicone ice cube buckets, the company has invested heavily in research and development. By collaborating with renowned scientists and experts in the field, the company has successfully developed advanced manufacturing processes that enhance the performance and durability of their products.Moreover, the company's manufacturing facilities adhere to stringent quality control measures to ensure that every bucket meets the highest industry standards. By prioritizing quality, the company aims to gain a competitive edge over its counterparts and establish itself as a trusted brand in the market.In addition to its focus on quality, the company recognizes the importance of sustainability and environmental consciousness. In line with China's commitment to reducing its carbon footprint, the company strives to minimize waste generation and optimize resource utilization during the manufacturing process. By adopting eco-friendly practices, the company aims to contribute to China's broader sustainability goals and foster a greener manufacturing ecosystem.With China's commitment to innovation, quality, and sustainability, the increased production of silicon carbide and silicone ice cube buckets is expected to meet the growing demand in both domestic and international markets. As Chinese manufacturers continue to invest in research and development and leverage their technological prowess, consumers can look forward to superior and reliable silicon carbide and silicone ice cube buckets that cater to their diverse needs.

Custom Plastic Injection Molding Services: A Guide to Creating Moulds

Plastic Injection Mold Company Moulds the Future with Innovative TechnologyPlastic injection mold technology has been revolutionizing the manufacturing industry for decades, and one company in particular is making a significant impact in this space. With innovative techniques and a commitment to excellence, [Company Name] is leading the way in producing high-quality plastic molds that are used in a variety of industries.The company, founded in [year], has quickly become a trusted name in the plastic injection mold industry. Their dedication to precision and quality has earned them a reputation for delivering superior products to their clients. With a state-of-the-art facility and a team of highly skilled engineers and technicians, [Company Name] is able to offer a wide range of plastic injection mold solutions to meet the diverse needs of their customers.One of the key differentiators for [Company Name] is their use of advanced technology in their manufacturing processes. They have invested in cutting-edge machinery and equipment that allows them to create intricate and complex molds with unparalleled precision. This commitment to innovation has enabled the company to stay ahead of the curve and continuously deliver exceptional results to their clients.In a recent interview, the CEO of [Company Name] expressed the company's dedication to pushing the boundaries of what is possible in plastic injection mold technology. He stated, "We are constantly challenging ourselves to explore new techniques and technologies that will allow us to deliver the best possible products to our clients. Our goal is to be at the forefront of innovation in this industry, and we are always looking for ways to improve and evolve our processes."One of the most impressive feats that [Company Name] has accomplished is their ability to mold plastic into intricate and complex shapes with remarkable precision. This has allowed them to produce molds for a wide range of products, including automotive parts, electronic components, medical devices, and consumer products. Their expertise in creating molds that meet the demanding requirements of these diverse industries has made them a go-to partner for many businesses.In addition to their technical capabilities, [Company Name] also emphasizes the importance of collaboration and communication with their clients. They work closely with each customer to understand their specific needs and requirements, and then develop customized solutions that meet or exceed expectations. This client-centric approach has earned them a loyal and satisfied customer base, further solidifying their position as a leader in the industry.As the demand for high-quality plastic molds continues to grow, [Company Name] is well-positioned to capitalize on this trend. With their proven track record of delivering exceptional results, their commitment to innovation, and their unwavering dedication to customer satisfaction, the company is poised to remain at the forefront of the plastic injection mold industry for years to come.Looking ahead, [Company Name] is focused on continuing to invest in new technology and talent to further elevate their capabilities. They are also exploring opportunities to expand their reach into new markets and industries, with the goal of serving an even broader range of clients with their top-of-the-line plastic injection mold solutions.In conclusion, [Company Name] is a shining example of a company that is driving innovation and excellence in the plastic injection mold industry. With their advanced technology, commitment to quality, and customer-focused approach, they are well-equipped to continue shaping the future of manufacturing with their cutting-edge plastic mold solutions.

SEO Title: Enhanced Air Cooler Mould for Plastic Injection Offers Efficient Cooling Solutions

Title: Innovative Plastic Injection Air Cooler Mould Revolutionizes Cooling SolutionsIntroduction:{Company Name}, a renowned manufacturer of cutting-edge plastic molds, has recently introduced a revolutionary plastic injection air cooler mould that promises to transform the way cooling solutions are produced. Designed with advanced technology and precision engineering, this ground-breaking mould offers enhanced performance, energy efficiency, and durability compared to traditional air cooling systems. This innovative product is set to revolutionize the cooling industry and address various cooling needs across sectors.Body:1. Understanding the Plastic Injection Air Cooler Mould:The plastic injection air cooler mould is expertly crafted using state-of-the-art technology and premium-quality materials. With a focus on functionality and reliability, this mould offers improved performance and increased longevity. Utilizing injection molding techniques, the mould enables the creation of custom-designed air coolers with precision and speed, catering to specific cooling requirements.2. Enhanced Performance and Efficiency:The plastic injection air cooler mould is engineered to deliver exceptional cooling performance while conserving energy. The design incorporates features such as optimized airflow and advanced cooling mechanisms, ensuring quick and efficient cooling of large areas. Moreover, the mould's superior insulation properties minimize energy consumption, making it an environmentally friendly choice for both residential and industrial cooling.3. Durability and Longevity:By utilizing high-quality, durable materials, the plastic injection air cooler mould guarantees a long lifespan, reducing the need for frequent replacements. The mould's robust construction ensures resistance against corrosion, wear, and tear, making it highly suitable for long-term usage in challenging environments. This durability translates to cost savings for consumers and businesses alike.4. Versatile Applications:The plastic injection air cooler mould is designed to cater to a wide range of cooling needs across various sectors. Its adaptable nature allows for the creation of air coolers suitable for residential buildings, commercial spaces, factories, warehouses, and agricultural settings. With customizable options available, these air coolers can be tailored to meet specific requirements, ensuring optimum comfort and cooling efficiency in diverse environments.5. Environmentally Friendly Features:The plastic injection air cooler mould aligns with the growing global focus on sustainability and eco-friendly practices. By incorporating energy-efficient components and reducing the overall carbon footprint, this mould contributes to the conservation of natural resources. The improved energy efficiency of the air coolers produced using this mould promotes responsible consumption while offering superior cooling capabilities.6. Advantages for Businesses:Businesses can greatly benefit from the plastic injection air cooler mould's advanced features. The increased cooling efficiency and durability contribute to a comfortable working environment, improving employee productivity and well-being. Additionally, cost savings from reduced energy consumption and maintenance expenses make this innovative mould an economically attractive choice for businesses seeking sustainable cooling solutions.Conclusion:With the introduction of the plastic injection air cooler mould, {Company Name} sets a new industry standard for cooling solutions. This innovative product offers enhanced performance, energy efficiency, and long-lasting durability compared to traditional air cooling systems. The mould's versatility and eco-friendly features further add to its appeal, making it a promising choice for diverse sectors and applications.As the demand for efficient and sustainable cooling continues to grow, the plastic injection air cooler mould remains at the forefront of providing practical, economical, and environmentally responsible solutions for a wide range of cooling requirements. With {Company Name} leading the way, the future of air cooling looks set to be revolutionized.

Custom Plastic Injection Molding for Switch Shell Mold Boxes

Plastic Box Injection, a leading manufacturer in the injection molding industry, has recently announced the launch of their new switch shell mold plastic box injection. This new product is expected to revolutionize the switch shell mold market with its innovative design and high-quality manufacturing.The switch shell mold plastic box injection is a key component in the production of switch shells, which are essential for the functionality of electronic devices. The new product is designed to meet the growing demand for durable and reliable switch shell molds in the consumer electronics and industrial equipment sectors.Plastic Box Injection has a strong track record of delivering high-quality injection molded products to its customers. With state-of-the-art manufacturing facilities and a team of experienced engineers and designers, the company is well-positioned to meet the needs of the rapidly evolving injection molding market."Our new switch shell mold plastic box injection is a game-changer for our customers," said a spokesperson from Plastic Box Injection. "We have invested heavily in research and development to ensure that this new product meets the highest standards of quality and performance. We are confident that it will set a new benchmark for switch shell molds in the industry."The switch shell mold plastic box injection is manufactured using the latest injection molding technology, which allows for precise and consistent molding of complex shapes and intricate designs. This ensures that the end product meets the exact specifications of the customer, with minimal waste and maximum efficiency.In addition to its advanced manufacturing capabilities, Plastic Box Injection is committed to sustainability and environmental responsibility. The company uses eco-friendly materials and processes in its production, and continuously seeks to minimize its carbon footprint."We understand the importance of sustainability in today's manufacturing industry," said the spokesperson. "That is why we have made it a priority to adopt sustainable practices in our operations. Our switch shell mold plastic box injection is manufactured with the latest eco-friendly materials, ensuring that it meets the highest environmental standards."As a customer-focused company, Plastic Box Injection places a strong emphasis on customer satisfaction and service. The company works closely with its customers to understand their specific needs and requirements, and strives to deliver customized solutions that exceed their expectations."We believe that our success is directly tied to the success of our customers," said the spokesperson. "That is why we are dedicated to providing the highest level of service and support to our customers. Our team of experts is always on hand to offer technical assistance and advice, and to ensure that our customers get the most out of our products."The launch of the switch shell mold plastic box injection is a clear demonstration of Plastic Box Injection's commitment to innovation and excellence in the injection molding industry. With its cutting-edge technology, sustainable practices, and customer-centric approach, the company is well-positioned to lead the market and set new standards for switch shell molds."We are excited about the potential of our new switch shell mold plastic box injection," said the spokesperson. "We believe that it will be a game-changer for the injection molding industry, and we are confident that it will be embraced by our customers. We are committed to pushing the boundaries of what is possible in injection molding, and this new product is just the beginning of what we have in store."Overall, the launch of the switch shell mold plastic box injection marks an important milestone for Plastic Box Injection and the injection molding industry. With its focus on innovation, quality, and sustainability, the company is well-positioned to meet the evolving needs of its customers and continue to lead the market in the years to come.