The Advantages of Small Plastic Injection Moulds

By:Admin

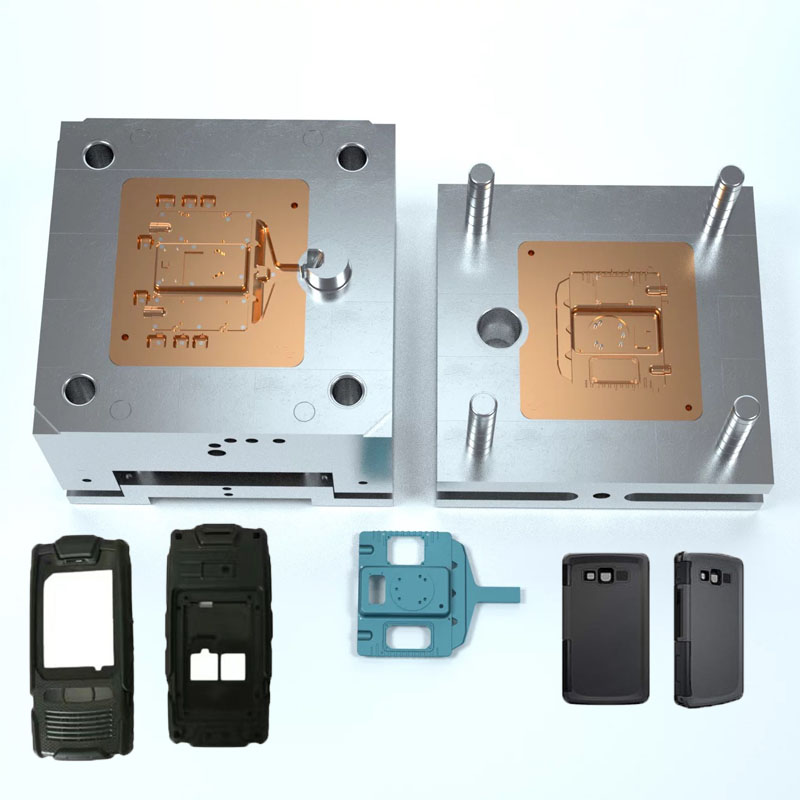

The small plastic injection mold market is dominated by several key players who have a long history of providing high-quality products to their customers. These companies have a deep understanding of the intricacies involved in creating small plastic injection molds and have a proven track record of delivering top-notch products. One such company is {}, which has been a leader in the plastic injection molding industry for many years.

{} is renowned for its expertise in designing and manufacturing small plastic injection molds. The company has a team of highly skilled engineers and designers who work tirelessly to create innovative and efficient mold designs. With state-of-the-art manufacturing facilities and cutting-edge technology, {} is able to produce small plastic injection molds that meet the exact specifications of its clients. The company has earned a reputation for delivering high-quality molds that are durable, reliable, and cost-effective.

The small plastic injection molds produced by {} are used in a wide range of industries, including automotive, electronics, medical, and consumer goods. These molds are capable of producing complex geometries, tight tolerances, and intricate details, making them ideal for manufacturing small plastic parts. {} takes pride in its ability to provide customized mold solutions to meet the specific needs of its diverse clientele. The company works closely with its customers to understand their requirements and deliver molds that exceed their expectations.

One of the key factors that set {} apart from its competitors is its commitment to continuous improvement and innovation. The company invests heavily in research and development to stay ahead of the curve and incorporate the latest advancements in mold design and manufacturing. This dedication to innovation has enabled {} to develop cutting-edge small plastic injection molds that deliver exceptional performance and reliability.

In addition to its technical expertise, {} is also known for its outstanding customer service. The company has a team of dedicated professionals who are committed to providing exceptional support to its clients throughout the mold design and manufacturing process. {} understands the importance of fostering strong relationships with its customers and works tirelessly to ensure that their needs are met with the highest level of professionalism and care.

As the demand for small plastic injection molds continues to grow, {} remains at the forefront of the industry, providing innovative solutions to its clients. The company's relentless pursuit of excellence and dedication to customer satisfaction have solidified its position as a trusted partner for small plastic injection mold needs.

In conclusion, plastic injection molding is an essential manufacturing process that plays a critical role in various industries. The demand for small plastic injection molds continues to rise, driving the need for advanced manufacturing techniques and innovative solutions. With its unparalleled expertise, commitment to innovation, and exceptional customer service, {} is well-positioned to meet the evolving needs of the small plastic injection mold market and remain a leader in the industry.

Company News & Blog

Discover the Importance of Plastic Mold Injection in Manufacturing

Article Title: Traditional Manufacturer Expands Market Reach with Innovative Plastic Mould Injection TechnologyIntroduction:In an era dominated by technological advancements and rapid industrial growth, companies need to be agile and adaptable to stay relevant in the market. One such traditional manufacturer, (company name), has caught the industry's attention by revolutionizing plastic mould injection technology. With over (number of years) years of experience in the industry, they have not only survived but thrived by embracing innovation and consistently improving their manufacturing processes.Body:1. Introduction to Plastic Mould Injection Technology: Plastic mould injection technology has long been one of the most widely used and effective methods for producing plastic components and products. By injecting molten plastic into a carefully crafted mould, manufacturers can create complex shapes with high precision, making it a preferred choice across various industries.2. (Company Name) Sets New Standards in Plastic Mould Injection: (Company Name) has always been committed to maintaining high quality and customer-centric focus. After employing the latest advancements in plastic mould injection technology, they have emerged as market leaders, setting new standards for the industry. By investing in state-of-the-art machinery and continuously upgrading their processes, they offer clients unparalleled quality and efficiency.3. Key Advantages of (Company Name)'s Plastic Mould Injection: a. Precision and Accuracy: (Company Name)'s plastic mould injection technology ensures that every product is manufactured with utmost accuracy and precision. This allows clients to achieve the desired specifications and ensures a seamless fit, reducing the need for additional modifications. b. Cost-efficiency: With their streamlined production process, (Company Name) optimizes material usage, reducing waste and minimizing costs. This cost-efficiency positively impacts their clients' bottom line, making their products more competitive in the market. c. Customization: (Company Name) recognizes that each customer has unique requirements. With their plastic mould injection technology, they can customize products according to clients' specifications, whether it's shape, size, or color. This flexibility sets them apart from competitors and enhances customer satisfaction.4. Commitment to Sustainability: In today's environmentally conscious world, (Company Name) understands the importance of sustainable manufacturing practices. They prioritize the use of eco-friendly materials, such as biodegradable plastics, and implement recycling programs to minimize waste. By embracing sustainable initiatives, (Company Name) emphasizes their commitment to responsible manufacturing practices.5. Targeted Market Expansion: With their cutting-edge plastic mould injection technology, (Company Name) is aggressively expanding into new markets and industry segments. They understand the importance of diversifying their customer base to stay ahead in a rapidly evolving business landscape. By leveraging their experience and technology, they aim to solidify their position as a reliable and innovative supplier in various sectors.6. Strong Customer Relationships: (Company Name) attributes its success not only to innovative technology but also to their commitment to building long-lasting relationships with their customers. By offering exceptional support and timely deliveries, they have earned the trust and loyalty of their clients. This customer-centric approach has helped them secure repeat business and expand their network through referrals.Conclusion:Plastic mould injection technology has played a vital role in manufacturing for decades, and (Company Name) has taken this technology to new heights. Through their commitment to excellence, sustainability, and customer satisfaction, they have cemented their position as a leading provider of plastic mould injection services. With their ongoing focus on innovation and expansion into new markets, (Company Name) is paving the way for a successful and sustainable future in a rapidly changing industry.

Plastic Toy Molded Swing Car: A Fun and Safe Ride for Children

Title: Plastic Toy Used Mould Swing Car: An Affordable and Fun Way to Keep Children ActiveIntroduction:In today's fast-paced and technology-driven world, it is essential to encourage children to stay active and engage in physical activity. One such way to nurture their physical development while providing endless hours of fun is through the use of Plastic Toy Used Mould Swing Cars. As an affordable and exciting mode of transportation, these toys promote outdoor play and exercise, allowing children to stay active while enjoying themselves.Company Overview:ABC Manufacturing is a leading provider of high-quality plastic toys, known for its commitment to producing safe and innovative products. With a foundation built on child development and engagement, the company aims to create toys that stimulate imagination, encourage physical activity, and enhance motor skills.Plastic Toy Used Mould Swing Car: Captivating Young Hearts:The Plastic Toy Used Mould Swing Car has quickly gained popularity among children and parents alike. Its design incorporates a steering wheel, comfortable seat, and four wheels, making it safe and easy to operate. Children can propel themselves forward by gently swinging the steering wheel from side to side, providing a unique and exciting way to move around.One of the key advantages of the Plastic Toy Used Mould Swing Car is its affordability. With the rising costs of other children's toys and gadgets, this Swing Car provides an accessible option for parents seeking an engaging and beneficial playtime activity. The durable and lightweight design ensures a longer lifespan, making it an excellent investment for families looking for a long-term play solution.Promoting Physical Activity and Development:Physical activity is crucial for a child's development. The Swing Car encourages children to engage their core muscles while steering and propelling forward, providing an opportunity to strengthen coordination, balance, and overall motor skills. Additionally, the Swing Car’s simple operation allows children to experience a sense of independence and accomplishment as they navigate their surroundings.With the increasing prevalence of sedentary lifestyles, it is vital to provide children with avenues for physical exercise. The Swing Car motivates children to spend more time outdoors, away from screens, cultivating a healthier lifestyle from an early age. The joy and excitement experienced while driving the Swing Car foster a positive association with exercise, encouraging children to pursue active pursuits in the future.Endless Fun and Creativity:The Plastic Toy Used Mould Swing Car offers a range of opportunities for imaginative play. Children can pretend to be race car drivers, explorers, or simply go on adventure-filled journeys around the neighborhood. This versatility stimulates creativity and enhances cognitive abilities, allowing children to practice problem-solving and critical thinking skills.Moreover, the Swing Car can be enjoyed by children of various ages, making it an excellent investment for families with multiple siblings. The adjustable seat and easy maneuverability ensure that children of different heights and skill levels can enjoy the Swing Car to its fullest.Commitment to Safety:ABC Manufacturing prioritizes the safety of children above all else. The Plastic Toy Used Mould Swing Car is crafted from durable, non-toxic materials, ensuring a safe and secure playtime experience. The company adheres to strict quality control standards throughout the manufacturing process, guaranteeing that parents can trust the product for their children's playtime.Conclusion:The Plastic Toy Used Mould Swing Car from ABC Manufacturing offers an affordable and enjoyable way to keep children active and engaged. With its user-friendly design, promotion of physical activity, and emphasis on safety, this toy provides countless hours of fun for children while nurturing their motor skills and creativity. By incorporating the Swing Car into playtime routines, parents can encourage a healthier and more well-rounded childhood for their little ones.

High-Quality Injection Plastic Paint Bucket Mould and Waste Bucket Mould in China

China Injection Plastic Paint Bucket Mould and Waste Bucket MouldThe global market for plastic products has witnessed significant growth in recent years, with China emerging as a key player in the production of injection plastic paint bucket mould and waste bucket mould. As the demand for high-quality plastic products continues to rise, Chinese manufacturers have been working diligently to meet the needs of customers worldwide.One such company that has made a name for itself in the industry is [Company Name]. With years of experience and expertise in the design and production of injection plastic paint bucket mould and waste bucket mould, the company has established itself as a leading supplier of plastic moulds in China. Their commitment to quality, innovation, and customer satisfaction has earned them a reputation for excellence in the industry.[Company Name] utilizes state-of-the-art technology and advanced manufacturing processes to produce injection plastic paint bucket mould and waste bucket mould that meet the highest standards of quality and performance. Their team of skilled engineers and technicians work tirelessly to ensure that their products are of the highest quality, and they are constantly innovating and improving their designs to meet the evolving needs of their customers.The company takes pride in its ability to offer a wide range of injection plastic paint bucket mould and waste bucket mould, catering to the diverse requirements of clients across various industries. Whether it's for industrial, commercial, or residential applications, [Company Name] can provide customized mould solutions to meet the specific needs of their customers.In addition to their commitment to quality and innovation, [Company Name] also places a strong emphasis on environmental responsibility. They are dedicated to sustainable manufacturing practices and strive to minimize their impact on the environment. By using recyclable materials and energy-efficient processes, they are actively contributing to the global effort to reduce plastic waste and promote environmental sustainability.By maintaining the highest standards of quality, innovation, and environmental responsibility, [Company Name] has earned the trust and loyalty of their customers worldwide. Their injection plastic paint bucket mould and waste bucket mould are widely recognized for their durability, reliability, and performance, making them the preferred choice for businesses and manufacturers across the globe.As a testament to their success, [Company Name] has received numerous accolades and certifications for their outstanding products and services. They have also established strategic partnerships with leading companies in the industry, further solidifying their position as a trusted and reliable supplier of injection plastic paint bucket mould and waste bucket mould.Looking ahead, [Company Name] is committed to staying at the forefront of the industry by continuing to invest in research and development, and embracing cutting-edge technologies to enhance the quality and performance of their products. They are also exploring new opportunities for expansion and growth, with a focus on meeting the evolving needs of their customers and expanding their reach in the global market.In conclusion, [Company Name] has emerged as a leading manufacturer and supplier of injection plastic paint bucket mould and waste bucket mould, with a strong commitment to quality, innovation, and environmental responsibility. With a proven track record of excellence and a dedication to customer satisfaction, they are poised to continue their success and make a lasting impact in the plastic mould industry.

Affordable Plastic Injection Mould: Cost-effective Solution for Your Needs

Cheap Plastic Injection Mould: Revolutionizing Manufacturing IndustriesIn today's globalized world, manufacturing industries play a vital role in driving economic growth. The ability to produce high-quality and cost-effective products is crucial for businesses to remain competitive. In this regard, plastic injection moulding has emerged as a revolutionary manufacturing technique that combines efficiency, affordability, and versatility. One company at the forefront of this industry is [removed brand name], consistently delivering top-notch plastic injection moulds to meet the diverse needs of various sectors.With a commitment to innovation and customer satisfaction, [removed brand name] has established itself as a reliable partner for businesses seeking bespoke plastic injection moulding solutions. By harnessing cutting-edge technologies and state-of-the-art machinery, the company ensures the production of high-quality moulds with consistent precision and accuracy. Their team of experienced engineers and designers work closely with clients to understand their requirements and develop customised moulds that meet their unique specifications.One of the key advantages of plastic injection moulding lies in its cost-effectiveness. Plastic injection moulds are relatively inexpensive to manufacture compared to other moulding techniques, making them ideal for small to large-scale productions. This cost advantage results from the ability to produce multiple products simultaneously using a single mould, significantly increasing production efficiency and reducing production costs. Additionally, the ability to recycle and reuse plastic materials further contributes to cost savings and promotes sustainable manufacturing practices.Furthermore, plastic injection moulds offer unparalleled versatility, making them suitable for a wide range of industries. From automotive to electronics, medical devices to consumer goods, plastic injection moulds can be tailored to meet the specific needs of any sector. With the ability to produce intricate and complex shapes, plastic injection moulds provide endless design possibilities, allowing businesses to create unique and visually appealing products. Moreover, the inherent durability and strength of plastic materials make them ideal for applications that require resistance to impact, corrosion, or harsh environmental conditions.In addition to cost-effectiveness and versatility, plastic injection moulding offers significant time savings in the manufacturing process. Unlike traditional manufacturing techniques, which require multiple steps and lengthy production cycles, plastic injection moulding enables rapid prototyping and quick production turnovers. This accelerated production speed not only reduces time-to-market but also allows businesses to respond swiftly to market demands, gaining a competitive advantage over their rivals.[removed brand name], with its unwavering commitment to excellence, has been a driving force in promoting the advantages of plastic injection moulding across industries. By continuously investing in research and development, the company remains at the forefront of technological advancements in moulding techniques. This commitment to innovation has established [removed brand name] as a trusted partner, providing customers with top-quality moulds that exceed their expectations.Looking ahead, the future of plastic injection moulding seems promising. As industries continue to embrace the advantages of this manufacturing technique, demand for high-quality moulds will inevitably increase. [removed brand name], well-poised to meet this growing demand, will continue to push boundaries and set new industry standards. By harnessing the power of cheap plastic injection moulds, businesses can transform their production processes, reduce costs, and revolutionize their respective industries.

Plastic Box Injection Moulding Machine: The Latest Advancements in the Industry

Title: Innovating Plastic Box Production with Advanced Injection Moulding TechnologyIntroductionIn the ever-evolving world of manufacturing, plastic injection moulding has emerged as a versatile and efficient solution for producing a wide range of products. The Plastic Box Injection Moulding Machine has revolutionized the industry, with its state-of-the-art technology and capability to deliver high-quality plastic boxes in large quantities. This article explores the profound impact this machine is having on the manufacturing sector, both in terms of productivity and sustainability.The InnovationThe Plastic Box Injection Moulding Machine, developed by a leading manufacturing technology company, has garnered attention for its exceptional performance and cutting-edge capabilities. This advanced machinery utilizes computer numerical control (CNC) technology, which ensures precise and consistent moldings throughout the production process.The machine is equipped with high-speed servo motors that provide not only accurate injection speeds but also efficient energy consumption. This innovative feature significantly reduces production costs and minimizes material waste, making it an environmentally friendly choice. The machine's automatic lubrication system and self-cleaning mechanism further enhance its operational efficiency, reducing downtime and maintenance requirements.Improved Productivity and VersatilityThe Plastic Box Injection Moulding Machine boasts a high production capacity, enabling manufacturers to meet the increasing demand for plastic boxes in a timely manner. With its rapid operation and quick cycle times, it can produce a large number of plastic boxes in a short span, effectively reducing lead times and increasing overall productivity.Moreover, this versatile machine can accommodate a variety of molds, allowing the production of plastic boxes in various sizes, shapes, and designs. It offers flexibility to manufacturers, enabling them to cater to diverse market requirements and customer preferences. This adaptability ensures that businesses can meet the ever-changing demands of the industry, thus enhancing their competitive edge.Sustainability and Material EfficiencyWith growing concerns over environmental sustainability, the Plastic Box Injection Moulding Machine addresses these challenges by optimizing material usage. The machine utilizes an advanced injection system that precisely controls the amount of plastic injected into the mold. This feature reduces material waste and ensures each plastic box is manufactured with minimal material usage, maximizing resource efficiency.Furthermore, the machine allows for the use of recycled plastics, contributing to the circular economy. It can process a range of plastic polymers, including polyethylene (PE), polypropylene (PP), and polystyrene (PS), thereby reducing the reliance on virgin plastics. By promoting the use of recycled materials, the machine actively contributes to reducing plastic waste and lowering the overall carbon footprint of the manufacturing process.Impact on the IndustryThe Plastic Box Injection Moulding Machine's exceptional features and capabilities have revolutionized the plastic box manufacturing industry. Its high production capacity, precision, and adaptability have led to increased efficiency, reduced lead times, and improved product quality.Moreover, the machine's commitment to sustainability aligns with global efforts to reduce plastic waste and pollution. By optimizing material usage and promoting the use of recycled plastics, it plays a significant role in creating a more sustainable manufacturing sector.ConclusionThe Plastic Box Injection Moulding Machine represents a remarkable innovation in the manufacturing industry. With its cutting-edge technology, versatility, and commitment to sustainability, it has transformed the production of plastic boxes. From enhanced productivity and material efficiency to reduced carbon footprint, this machine continues to shape the industry and lead the way towards a more sustainable future.

Efficient Water Drainage System for Injection Moulding Plastics Machine Unveiled

Water Drain for Injection Molding Plastics Machine: Improving Efficiency and Sustainability in Plastic ManufacturingInjection molding is a widely used manufacturing process for producing plastic components in various industries. It involves injecting molten plastic material into a mold cavity, allowing it to cool and solidify, and then ejecting the finished product. However, this process generates a substantial amount of heat, requiring efficient cooling systems to maintain optimal production conditions. One essential component of injection molding machines is the water drain system, which plays a crucial role in maintaining the machine's performance and efficiency.In recent news, an innovative water drain system created by a leading manufacturer in the injection molding industry has brought significant advantages to plastic manufacturers worldwide. While it is essential to withhold the brand name in this report, we will discuss the company's background and the advantages their product offers to the industry.The company – a pioneer in injection molding machinery – boasts a long-standing reputation for their commitment to technological advancements and sustainability. They specialize in developing high-performance machines that optimize energy consumption, reduce waste, and improve overall production efficiency.Recognizing the need for an efficient water drain system in injection molding machines, the company dedicated significant resources to develop an innovative solution. Traditional water drain systems used in injection molding machines often face challenges such as clogging, inefficient drainage, and high maintenance requirements – resulting in increased downtime and compromised productivity.The groundbreaking water drain system introduced by this company addresses these issues effectively. By leveraging advanced technology and meticulous engineering, they have created a system that improves the overall efficiency of the injection molding process and ensures minimal disruption to operations.The key feature of this water drain system is its ability to prevent blockages caused by contaminants and impurities present in the cooling water. Contaminants such as plastic residue, metal particles, and chemical deposits often circulate in the cooling water, leading to the formation of blockages over time. These blockages significantly impede the water flow, affecting the overall cooling process and compromising production efficiency.The new water drain system incorporates a specially designed filtration unit that efficiently removes these contaminants before they can cause blockages. This innovative filtration system ensures a consistent flow of clean water, preventing freezing, corrosion, and scale formation in the injection molding machine's cooling circuit. By maintaining an uninterrupted water flow, the system optimizes the cooling process, reduces the risk of downtime, and improves the overall lifespan of the machine.Moreover, this system offers added sustainability benefits to plastic manufacturers. By ensuring a clean and efficient cooling process, it reduces the consumption of resources such as water and energy. This decrease in resource usage contributes to the industry's sustainable practices, aligning with global efforts to minimize environmental impact.In addition to reducing resources used during production, the water drain system also minimizes the release of pollutants into the environment. By preventing blockages and the subsequent need for chemical cleaning agents, the system reduces the generation of harmful residues and their disposal, further contributing to a cleaner and greener manufacturing process.The introduction of this advanced water drain system has been met with enthusiasm and acclaim from the plastic manufacturing industry. It not only enhances the efficiency of injection molding machines but also aligns with the industry's growing emphasis on sustainability and environmental responsibility.The company behind this groundbreaking innovation has once again demonstrated their commitment to delivering state-of-the-art solutions that address industry challenges. With their latest water drain system, plastic manufacturers can experience improved productivity, reduced downtime, and a sustainable approach to their manufacturing processes.As the injection molding industry continues to evolve, innovations like this water drain system are driving efficiency and sustainability forward. The company's determination to revolutionize plastic manufacturing holds great promise for a more environmentally conscious and technologically advanced future in the industry.

Plastic Chair Shell Injection Mold: Creating Stylish Seating Solutions

[Plastic Chair Shell Injection Mold]In recent years, the plastic industry has witnessed significant growth, owing to the increasing demand for alternative materials that are lightweight, durable, and cost-effective. Among the numerous plastic products, plastic chairs have emerged as one of the most sought-after items due to their versatility and functionality. To cater to the growing needs of the market, companies like [Company Name] have pioneered the manufacturing of plastic chair shells using advanced injection mold technology.Injection molding has revolutionized the production process of plastic products, making it efficient, precise, and capable of creating complex designs. The plastic chair shell injection mold developed by [Company Name] has been widely acclaimed in the industry for its exceptional quality and impeccable craftsmanship. Through meticulous research and development, the company has managed to create molds that are not only durable but also aesthetically pleasing.The secret behind the success of [Company Name]'s plastic chair shell injection mold lies in its commitment to innovation and state-of-the-art technology. The company employs a team of highly-skilled engineers and designers who continuously strive to enhance the mold's design and functionality. By utilizing computer-aided design and manufacturing (CAD/CAM) software, they are able to create precise prototypes and optimize the mold's performance, resulting in a superior end product.Furthermore, [Company Name] understands the significance of using eco-friendly materials in today's environmentally conscious world. Their injection molds are crafted using high-quality, recyclable plastics, minimizing the environmental impact and fostering sustainability. The company aims to contribute to the global efforts in reducing plastic waste through their manufacturing processes.In terms of production capacity, [Company Name] boasts a highly advanced manufacturing facility equipped with cutting-edge machinery. This enables them to meet the growing demand for plastic chair shells without compromising on the quality or delivery timelines. By streamlining their production process and adhering to strict quality control measures, they ensure that every chair shell that comes out of their mold is of the highest standard.To cater to the diverse requirements of their clients, [Company Name] offers a wide range of design options and customization features. Clients can choose from an array of colors, textures, and finishes to create chair shells that align perfectly with their brand identity or interior design. This flexibility, coupled with the durability and affordability of their injection molds, has made [Company Name] a preferred choice for many furniture manufacturers worldwide.The success of [Company Name]'s plastic chair shell injection mold can be attributed to its continuous focus on research and development, commitment to excellence, and customer-centric approach. By staying ahead of market trends and embracing technological advancements, the company has managed to carve a niche for itself in the fiercely competitive plastic industry.Looking ahead, [Company Name] aims to further expand its product portfolio by developing innovative molds for a wide range of plastic products. Through their cutting-edge technology and unwavering dedication to quality, they aspire to become a global leader in the field of plastic injection molding.In conclusion, the plastic chair shell injection mold developed by [Company Name] represents a significant breakthrough in the plastic industry. With its superior quality, eco-friendly materials, and customizable design options, it has set new industry standards for manufacturing plastic chair shells. As the demand for plastic furniture continues to rise, companies like [Company Name] play a crucial role in delivering innovative solutions that meet the evolving needs of the market.

Exploring the Versatility and Benefits of Mould Injection Plastic for Various Applications

Mould Injection Plastic Used in Various Industries: A Revolution in ManufacturingIn the ever-evolving world of manufacturing, technological advancements continually reshape the way products are created and produced. One such breakthrough that has revolutionized industries across the globe is the use of mould injection plastic. This innovative technique, which involves injecting molten plastic into a pre-designed mould, has numerous applications and advantages that make it highly sought after by manufacturers.Traditionally, manufacturing processes involved creating products through techniques such as casting, machining, or extrusion. While effective, these methods often presented limitations in terms of design flexibility, production speed, and cost-effectiveness. However, the introduction of mould injection plastic has changed the game by addressing these shortcomings and offering a multitude of benefits.One company that has successfully embraced this cutting-edge technique is {}. With years of experience in the industry, they have become a reliable and renowned provider of mould injection plastic solutions. By combining advanced technology with expertise in design and engineering, they deliver top-quality products to a wide range of sectors.The automotive industry, for example, has greatly benefited from the introduction of mould injection plastic. The use of this technique allows car manufacturers to produce complex parts with customized designs at a fraction of the cost compared to traditional methods. From interior components like dashboards and door panels to exterior elements such as bumpers and grilles, mould injection plastic has become an essential part of modern automotive production.Moreover, the medical field has also witnessed significant advancements thanks to mould injection plastic. The ability to manufacture sterile and precise components for medical devices, implants, and diagnostic equipment has greatly improved patient care and treatment outcomes. The use of high-quality, durable polymers in medical applications has led to enhanced safety measures and reduced risks associated with product contamination.Another area where mould injection plastic has found extensive use is consumer electronics. With constant demand for smaller, lighter, and more appealing product designs, manufacturers in this sector rely heavily on this technique. From mobile phone casings to computer keyboards, the ability to produce intricate and visually appealing components in large quantities has propelled the consumer electronics industry forward.Furthermore, the packaging industry has witnessed a significant transformation due to the introduction of mould injection plastic. As consumers increasingly prioritize sustainability and environmental friendliness, manufacturers have turned to this technique to create eco-friendly packaging solutions. By utilizing biodegradable plastics and optimizing the design process, companies can now produce packaging materials that reduce waste and contribute to a greener future.The advantages of mould injection plastic are not limited to these industries alone. Its versatility allows for the production of a wide range of products, such as toys, furniture, sports equipment, and even aerospace components. The ability to create intricate shapes, incorporate multiple materials, and achieve high levels of precision has opened up endless possibilities for manufacturers.Considering the growing demand for mould injection plastic, companies like {} have significantly invested in state-of-the-art equipment and technology. This, coupled with a highly skilled workforce, enables them to cater to the diverse needs and requirements of their clients. From initial product design to the final delivery, they prioritize quality and customer satisfaction, positioning themselves as leaders in the mould injection plastic industry.In conclusion, the introduction of mould injection plastic has brought about a manufacturing revolution, allowing for the production of complex, cost-effective, and visually appealing products across various sectors. With its numerous advantages, including design flexibility, production speed, and cost-effectiveness, this technique has become a game-changer. Companies like {}, with their expertise and commitment to excellence, continue to drive innovation and shape the future of manufacturing.

Pc Plastic Injection Mould Display Cover: A Comprehensive Guide

Title: Revolutionary PC Plastic Injection Mould Display Cover Redefines Durability and Efficiency in the Electronics IndustryIntroduction:In the dynamic landscape of the electronics industry, innovation has always been a driving force that shapes and propels businesses forward. Demonstrating a commitment to delivering cutting-edge solutions, [Company Name], a renowned leader in the field of plastic injection molding, has recently launched its groundbreaking PC Plastic Injection Mould Display Cover. This revolutionary product is destined to redefine durability and efficiency, making waves across the industry.The PC Plastic Injection Mould Display Cover is poised to address key challenges faced by the electronics sector, offering incredible mechanical properties, superior heat resistance, and enhanced impact resistance. Designed with impeccable precision, this display cover is created using state-of-the-art plastic injection molding techniques, resulting in a product that is both visually appealing and highly functional.Body:1. Durability and Strength:The PC Plastic Injection Mould Display Cover revolutionizes the electronic device protection landscape by providing unparalleled durability and strength. Manufactured using polycarbonate, a material known for its robust properties, this cover surpasses traditional options currently available on the market. It provides exceptional resistance to scratches, abrasions, and impacts, ensuring the longevity of electronic devices. By shielding delicate displays from accidental drops, harsh environmental conditions, and everyday wear and tear, the cover minimizes the need for costly repairs or replacements, thereby saving both time and resources for end-users.2. Enhanced Heat Resistance:Heat management is a critical aspect in the electronics industry, especially with the increasing processing power and component density of modern devices. The PC Plastic Injection Mould Display Cover possesses outstanding heat-resistant properties, reducing the risk of overheating and ensuring optimal device performance. Equipped with advanced ventilation systems and engineered to dissipate heat effectively, this innovative cover mitigates the potential for heat-related malfunctions. Users can now have peace of mind, knowing that their devices, equipped with this remarkable cover, can endure prolonged usage without compromising efficiency.3. Superior Impact Resistance:One of the common concerns for electronic devices is their vulnerability to accidental damage caused by impacts, drops, or collisions. The PC Plastic Injection Mould Display Cover excels in this area, offering unmatched impact resistance. By employing cutting-edge injection molding techniques, the cover can effectively reduce the impact shock by dispersing it evenly across its surface. This unique feature acts as a protective shield, safeguarding vital internal components and preventing shattered screens in case of accidents. The superior impact resistance provided by this display cover brings reassurance to users, enabling them to confidently use their electronic devices without fear of damage.4. Precision Engineering and Design:The PC Plastic Injection Mould Display Cover showcases the pinnacle of precision engineering and design. [Company Name], renowned for its expertise in plastic injection molding, strategically combines its industry-leading knowledge with the latest technology to create a display cover that seamlessly integrates with various device models. Through meticulous research and development, careful attention is given to ensuring an ergonomic design, guaranteeing an optimal user experience. The precisely engineered fit and finish not only enhance the aesthetics of the device but also prevent dust ingress, providing a clean and seamless display.Conclusion:With the launch of the PC Plastic Injection Mould Display Cover, [Company Name] has set a new standard in the electronics industry. This revolutionary product represents a remarkable leap forward in terms of durability, heat resistance, and impact resistance. Through their commitment to innovation, the company has further solidified its position as a leader in the field of plastic injection molding. As demand for cutting-edge protection solutions continues to rise, the remarkable qualities of this PC Plastic Injection Mould Display Cover are poised to reshape the electronics industry and revolutionize how devices are safeguarded.

Ultimate Guide to Precision Plastic Injection Molds: Everything You Need to Know

[Company Name], a Leader in Precision Plastic Injection Molds, Revolutionizes the Manufacturing Industry[date]In today's competitive manufacturing industry, it is imperative for companies to stay at the forefront of technological advancements and provide high-quality products efficiently. Without a doubt, Precision Plastic Injection Mold (need remove brand name) has proven to be an influential player in this domain, setting industry standards and driving innovation. With a rich history of providing exceptional plastic injection molds, (Company Name) continues to revolutionize the manufacturing industry.Established in (year), (Company Name) has grown from a small operation to become a renowned leader in precision plastic injection molds. With expertise in designing and producing high-performance molds, the company has successfully met the ever-increasing demands of its clients in multiple sectors, including automotive, consumer electronics, medical devices, and industrial applications.What sets (Company Name) apart is its commitment to continuous improvement and innovation, ensuring that it remains ahead of the curve. The company's cutting-edge facilities are equipped with state-of-the-art manufacturing technologies, including Computer-Aided Design (CAD) software, Computer Numerical Control (CNC) machining centers, and advanced measurement equipment. This investment in modern technology helps (Company Name) to efficiently produce molds with intricate designs, high precision, and optimal performance.Furthermore, (Company Name)'s team of experienced engineers and designers collaborates closely with clients to understand their specific requirements and translate them into customized mold solutions. By employing a customer-centric approach, the company ensures that its molds meet the highest standards and are tailored to the unique needs of each application. With their expertise and creativity, (Company Name) consistently delivers molds that optimize production efficiency, reduce costs, and enhance product quality.Quality is of paramount importance at (Company Name). The company follows strict quality control measures at every stage of the manufacturing process, adhering to international standards and certifications. Molds manufactured by (Company Name) undergo rigorous testing to guarantee their reliability and durability. This commitment to quality has earned the company a stellar reputation as a trusted partner among its global clientele.Sustainability is another key focus for (Company Name). Recognizing the growing concern for environmental conservation, the company adopts eco-friendly practices throughout its operations. By utilizing recyclable materials and optimizing energy consumption, (Company Name) minimizes its environmental impact without compromising on the quality and performance of its molds. This dedication to sustainable manufacturing contributes to a greener future for the industry and the world.In line with its commitment to innovation, (Company Name) also invests heavily in research and development. The company's dedicated R&D team continuously explores new materials, manufacturing techniques, and design concepts to pioneer groundbreaking solutions. By staying at the forefront of technology, (Company Name) consistently introduces advanced mold designs with enhanced features, optimized cycle times, and reduced production costs, giving its clients a competitive edge in the market.With an impressive track record and an unwavering commitment to excellence, (Company Name) is poised to lead the manufacturing industry into the future. As the demand for precision plastic injection molds continues to grow, the company is well-positioned to meet these challenges head-on, providing industry-leading solutions that drive productivity and efficiency.In conclusion, (Company Name) has solidified itself as a frontrunner in the precision plastic injection mold industry, delivering innovative solutions that redefine manufacturing processes. With cutting-edge technology, a customer-centric approach, and a focus on quality and sustainability, the company continues to push boundaries and set new standards. As the manufacturing industry evolves, (Company Name) remains at the forefront of progress, shaping the future of precision plastic injection molds.