Understanding the Process of Mold Injection Plastic Molding

By:Admin

The use of mold injection plastic molding has gained widespread popularity in various industries due to its ability to produce high-quality and precision parts at a relatively low cost. This process is highly versatile and can be used to manufacture a wide variety of products, ranging from small and intricate components to larger and more complex parts.

{Company} is a leading manufacturer and supplier of mold injection plastic molding solutions, catering to the needs of a wide range of industries. With state-of-the-art facilities and a team of experienced professionals, the company has established itself as a trusted partner for companies seeking high-quality plastic molding services.

The company offers a comprehensive range of mold injection plastic molding services, including design and engineering, tooling, and production. They have the expertise and capabilities to handle projects of all sizes and complexities, from prototype development to full-scale production runs. Their advanced manufacturing processes and quality control measures ensure that the final products meet the highest standards and specifications.

One of the key advantages of {Company}'s mold injection plastic molding services is their ability to provide cost-effective solutions without compromising on quality. They utilize advanced technologies and efficient production methods to optimize the manufacturing process, resulting in reduced production times and lower overall costs. This makes their services an attractive option for companies looking to streamline their production processes and enhance their bottom line.

{Company} is also committed to sustainability and environmental responsibility. They have implemented various measures to minimize waste and energy consumption in their manufacturing processes, ensuring that their operations have minimal impact on the environment. Additionally, they offer a range of eco-friendly materials and options to clients who are looking to reduce their carbon footprint and enhance their sustainability efforts.

Furthermore, {Company} boasts a strong commitment to customer satisfaction and support. Their dedicated team works closely with clients to understand their specific requirements and provide tailored solutions to meet their needs. They offer comprehensive support throughout the entire manufacturing process, from initial design and prototyping to final production and delivery, ensuring that the client's expectations are met every step of the way.

With their focus on innovation and continuous improvement, {Company} is at the forefront of mold injection plastic molding technology. They constantly invest in research and development to stay abreast of the latest advancements in the industry, enabling them to offer cutting-edge solutions and stay ahead of the competition.

In conclusion, mold injection plastic molding is a highly effective manufacturing process that has revolutionized the production of plastic components and products. {Company} is a leading provider of mold injection plastic molding services, offering a comprehensive range of solutions to meet the diverse needs of their clients. With their state-of-the-art facilities, commitment to quality, sustainability efforts, and customer-centric approach, they have established themselves as a trusted partner for companies seeking high-quality and cost-effective plastic molding solutions.

Company News & Blog

Top quality injection molding die moulds for sale - find out more!

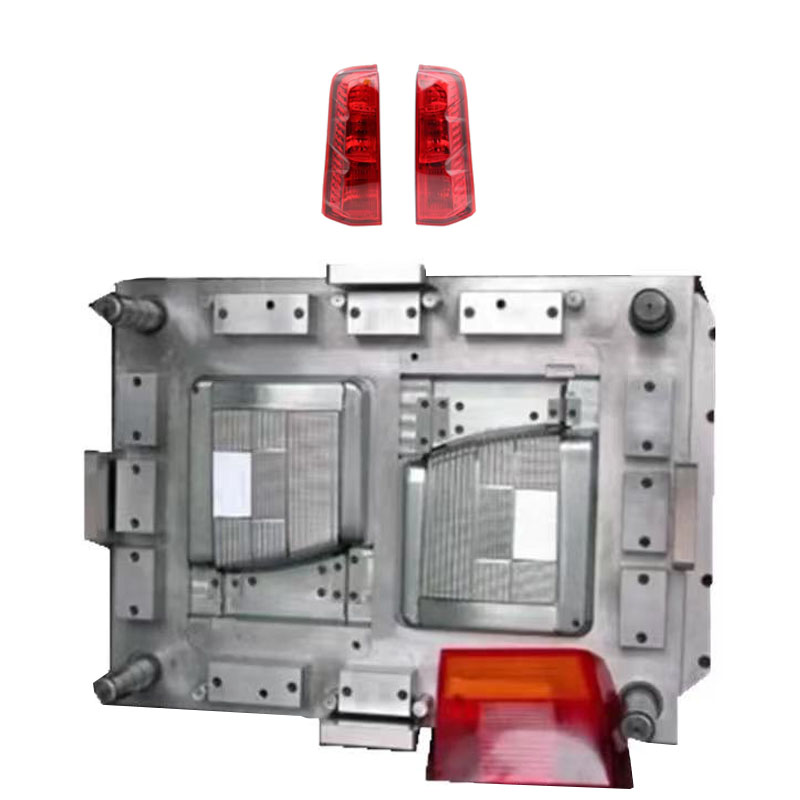

Introduction:Injection molding is a manufacturing process used for producing parts by injecting molten material into a mold. This process is widely used in the production of various products, including automotive parts, packaging, and consumer goods. One of the key components in injection molding is the die mold, which plays a crucial role in determining the quality and precision of the final products. In recent news, the renowned company {}, specializing in the design and production of injection molding die molds, has made significant advancements in their technology, which are set to revolutionize the industry.Revolutionizing Injection Molding Die Molds:{}, a leader in the field of injection molding technology, has made groundbreaking developments in their die mold designs. These advancements come as a result of years of research and development, as well as a deep understanding of the needs and challenges faced by manufacturers in the industry. The company has successfully developed a new range of die molds that offer improved precision, durability, and efficiency, setting a new standard for the industry.One of the key innovations in the new die molds is the integration of advanced materials and manufacturing techniques. By utilizing high-quality materials and state-of-the-art manufacturing processes, {} has been able to significantly enhance the performance and longevity of their die molds. This means that manufacturers can expect higher productivity and lower maintenance costs, ultimately leading to improved profitability and competitiveness in the market.Furthermore, {} has introduced new design features that enable greater flexibility and customization in the production process. The company understands the diverse needs of manufacturers in different industries, and as such, they have developed die molds that can be easily adapted to various production requirements. Whether it is complex geometries, precise specifications, or unique material properties, {} has the capability to provide tailored solutions that meet the exact needs of their customers.The advancements in the die mold technology also address the growing demand for sustainability and environmental responsibility in the manufacturing sector. By optimizing the design and production processes, {} has been able to reduce material waste, energy consumption, and emissions, contributing to a more sustainable and eco-friendly manufacturing practice. This is a commendable achievement in an industry that is constantly seeking ways to minimize its environmental impact.Partnership and Collaboration:In order to bring these groundbreaking advancements to the market, {} has been actively seeking partnerships and collaborations with manufacturers and industry experts. By working closely with their customers, the company aims to gain valuable insights into the specific challenges and requirements faced by manufacturers, allowing them to further refine and optimize their die mold designs. Through these collaborative efforts, {} is able to provide tailored solutions that perfectly align with the needs of their customers, ensuring maximum satisfaction and success in their production processes.Potential Impact:The advancements made by {} in the field of injection molding die molds are expected to have a substantial impact on the industry as a whole. Manufacturers can look forward to greater efficiency, precision, and versatility in their production processes, ultimately leading to improved product quality and reduced time-to-market. With the new die molds from {}, manufacturers will have the tools they need to stay ahead of the competition and meet the ever-increasing demands of the market.Conclusion:In conclusion, the developments made by {} in the design and production of injection molding die molds are set to revolutionize the industry. With their advanced technology, high-quality materials, and commitment to customer satisfaction, {} is paving the way for a new era of innovation and excellence in injection molding. Manufacturers can now look forward to a future of greater efficiency, flexibility, and sustainability, thanks to the groundbreaking advancements made by {}.

Cost-effective Injection Mold Solutions for Manufacturing

Cheap Injection Mold Manufacturer, a leading provider of high-quality and affordable injection molds, announced today the expansion of their product line to include a wide range of new mold designs. The company, which has been in operation for over 20 years, prides itself on delivering top-notch molds at competitive prices to businesses across various industries.The new injection mold designs offered by Cheap Injection Mold Manufacturer are expected to meet the growing demand for cost-effective and reliable mold solutions. With a focus on innovation and quality, the company has consistently met the needs of their customers while staying competitive in the market. The expanded product line will enable businesses to access a wider range of options for their injection molding needs, ensuring that they can find the perfect mold for their specific requirements.The injection mold industry plays a crucial role in the manufacturing sector, as molds are used to create a vast array of plastic products that we use every day. From consumer goods to automotive parts, injection molding is utilized in numerous industries to produce high-quality, durable products. As such, having access to affordable and reliable injection molds is essential for businesses looking to stay ahead in today's competitive market.Cheap Injection Mold Manufacturer has built a solid reputation for delivering superior molds that are not only cost-effective but also durable and precise. Their team of experienced professionals has extensive knowledge of injection molding technology and can provide valuable insights and guidance to their customers. By continually investing in the latest equipment and technologies, the company ensures that they are able to meet the evolving needs of their clients and deliver top-notch molds that exceed expectations.The expanded product line includes a variety of new mold designs, ranging from standard to custom options, to cater to a diverse range of industries and applications. Whether a business requires a simple prototype mold or a complex multi-cavity mold, Cheap Injection Mold Manufacturer is well-equipped to deliver a solution that meets their unique needs. The company's dedication to customer satisfaction and their commitment to quality assurance make them a trusted partner for businesses seeking affordable injection molding solutions.In addition to expanding their product line, Cheap Injection Mold Manufacturer also offers a comprehensive range of services, including mold design, prototyping, tooling, and production. Their in-house team of experts works closely with clients to understand their specific requirements and provide tailored solutions that align with their production goals and budget. This personalized approach sets the company apart from the competition and has earned them a loyal customer base over the years.For businesses looking to reduce costs without compromising on quality, Cheap Injection Mold Manufacturer's expanded product line offers an array of affordable mold options that are designed to meet their needs. By leveraging their expertise and state-of-the-art facilities, the company is well-positioned to continue delivering exceptional injection molds that help their customers stay competitive in the market.With the unveiling of their new mold designs, Cheap Injection Mold Manufacturer is poised to further solidify their position as a leading provider of cost-effective and reliable injection molding solutions. The company's unwavering commitment to quality, innovation, and customer satisfaction ensures that businesses can trust them to deliver the molds they need to bring their products to market. As the demand for affordable injection molds continues to grow, Cheap Injection Mold Manufacturer remains dedicated to providing top-notch solutions that enable their customers to thrive in today's fast-paced manufacturing landscape.

Innovative Injection Molded Design Unveiled in Latest News

The company, a leading provider of injection molding solutions, has recently announced the launch of a new design injection molded product. The new design promises to revolutionize the industry with its innovative features and superior quality. This development marks a significant milestone for the company, as it continues to push the boundaries of injection molding technology and deliver cutting-edge solutions to its customers.The new design injection molded product is the result of extensive research and development efforts by the company's team of experts. Leveraging the latest advancements in injection molding technology, the product has been engineered to meet the highest industry standards and deliver exceptional performance. From its precise dimensions to its flawless finish, every aspect of the product has been meticulously designed to ensure superior functionality and durability.One of the key highlights of the new design injection molded product is its versatility. The product is capable of meeting a wide range of customer requirements, making it an ideal choice for various applications across different industries. Whether it's automotive, electronics, medical, or consumer goods, the product offers unmatched flexibility and adaptability, making it a valuable asset for businesses seeking reliable injection molding solutions.In addition to its versatility, the new design injection molded product also boasts of an ergonomic and user-friendly design. The company has gone to great lengths to ensure that the product is easy to use and integrate into existing manufacturing processes. This not only streamlines production processes but also enhances overall efficiency, resulting in cost savings and higher productivity for businesses.Furthermore, the new design injection molded product offers improved strength and durability, making it a long-lasting and reliable solution for manufacturers. The company has utilized advanced materials and manufacturing techniques to enhance the product's structural integrity, allowing it to withstand the most demanding operating conditions. This durability ensures that the product provides a long service life, ultimately contributing to lower maintenance costs and greater ROI for customers.With the launch of the new design injection molded product, the company reinforces its commitment to delivering innovative and high-quality solutions to its customers. This latest addition to the company's portfolio further solidifies its position as a trusted partner for businesses seeking top-notch injection molding capabilities. Customers can now rely on the company's expertise and state-of-the-art technology to meet their specific needs and stay ahead of the competition.In conclusion, the new design injection molded product represents a major leap forward for the company and the injection molding industry as a whole. By pushing the boundaries of technology and innovation, the company continues to set new standards for quality, performance, and reliability. With its unmatched versatility, user-friendly design, and exceptional durability, the product is set to make a significant impact across various industries. As the company looks ahead, it remains dedicated to developing cutting-edge solutions that empower businesses and drive success in the dynamic world of injection molding.

Earphone Injection Molding: The Process and Benefits of Plastic Shell Molding

Plastic Shell Earphone Injection MoldingIn today's fast-paced and modern world, the demand for high-quality earphones is ever-increasing. Whether it's for listening to music, taking calls, or watching videos, earphones have become an essential accessory for people on the go. With this rise in demand, the need for efficient and advanced manufacturing processes for earphones has also increased. This is where the plastic shell earphone injection molding process comes into play.Injection molding is a manufacturing process for producing parts by injecting material into a mold. This process is commonly used for the mass production of items such as earphone shells, as it allows for high volumes of production at a rapid pace. By utilizing injection molding for earphone shells, companies can streamline their manufacturing processes and meet the growing consumer demand for high-quality earphones.One company that has mastered the art of plastic shell earphone injection molding is {}. With years of experience in the industry, {} has become a leader in the manufacturing of earphone shells through injection molding. The company's dedication to quality, efficiency, and innovation has allowed them to stay ahead of the curve and provide their clients with top-notch products.{}'s injection molding process for earphone shells involves several key steps. First, a mold is created based on the design specifications provided by the client. The mold is then filled with a thermoplastic material, such as polypropylene or polycarbonate, which is heated to a high temperature and injected into the mold at high pressure. This allows for the material to take the shape of the mold, resulting in a precise and uniform earphone shell.One of the main advantages of plastic shell earphone injection molding is the ability to produce complex and intricate designs with ease. This process enables {} to create earphone shells with intricate patterns and designs that would be difficult to achieve using other manufacturing methods. Additionally, injection molding allows for a high degree of consistency and repeatability, ensuring that each earphone shell meets the same high standards of quality.In addition to the technical aspects of injection molding, {} also places a strong emphasis on sustainability and environmental responsibility. The company is committed to reducing waste and minimizing its environmental impact throughout the manufacturing process. By using recyclable materials and implementing efficient production techniques, {} is able to create earphone shells with minimal environmental footprint.Furthermore, {} prides itself on its ability to work closely with clients to understand their specific needs and deliver custom solutions. Whether a client requires a specific color, finish, or material for their earphone shells, {} has the expertise and flexibility to accommodate these requirements. This personalized approach to manufacturing sets {} apart from its competitors and has earned the company a strong reputation in the industry.As the demand for high-quality earphones continues to grow, the plastic shell earphone injection molding process will play a crucial role in meeting this demand. With its efficiency, precision, and versatility, injection molding allows companies like {} to produce earphone shells at scale without compromising on quality. As a leader in the industry, {} is well-positioned to continue driving innovation and pushing the boundaries of what is possible in the world of earphone manufacturing.In conclusion, plastic shell earphone injection molding is a highly efficient and effective manufacturing process that is essential for meeting the growing demand for high-quality earphones. With companies like {} leading the way in this field, consumers can expect to see a continued evolution in the design and production of earphone shells, ensuring that they have access to top-of-the-line products for their audio needs.

Discover the Latest Prices of Silicon Carbide Buckets and Silicone Ice Cube Buckets in China

China Plans to Increase Production of Silicon Carbide Bucket and Silicone Ice Cube Bucket to Meet Growing DemandChina, a global leader in manufacturing and technological advancements, is set to boost its production of silicon carbide and silicone ice cube buckets to cater to the increasing demand in both domestic and international markets.Silicon carbide, a synthetic material made from a combination of silicon and carbon, possesses exceptional properties that make it highly desirable for a wide range of industrial applications. Known for its hardness, durability, and thermal conductivity, silicon carbide is extensively used in manufacturing buckets for various purposes, including industrial processes, construction, and even for household use. With its ability to withstand extreme temperatures and resist corrosion, silicon carbide buckets have become popular for their longevity and reliability.Similarly, silicone ice cube buckets have gained popularity due to their flexibility, non-stick properties, and ability to withstand extreme temperatures. Made from silicone, a synthetic rubber-like material, these buckets are used for freezing water and other liquids to form ice cubes. Silicone ice cube buckets have emerged as a convenient and hygienic alternative to traditional ice trays, making them a sought-after commodity in households, restaurants, and bars.Recognizing the expanding demand for silicon carbide and silicone ice cube buckets, Chinese manufacturers are taking significant steps to increase their production capacity. The surge in demand can be attributed to the growing industrial sector in China, as well as the rising popularity of silicone-based products globally. China's robust manufacturing ecosystem and technological expertise have made it an ideal location for the production of these buckets, enabling faster market penetration and competitive pricing.Several leading Chinese manufacturers, supported by the latest technologies and state-of-the-art facilities, are poised to become key players in the silicon carbide and silicone ice cube bucket market. These companies aim to leverage their expertise in material science and engineering to develop innovative products that meet the evolving needs of consumers.One such company, with its strong commitment to quality and innovation, is a prominent player in the industry. With a vision to offer superior silicon carbide and silicone ice cube buckets, the company has invested heavily in research and development. By collaborating with renowned scientists and experts in the field, the company has successfully developed advanced manufacturing processes that enhance the performance and durability of their products.Moreover, the company's manufacturing facilities adhere to stringent quality control measures to ensure that every bucket meets the highest industry standards. By prioritizing quality, the company aims to gain a competitive edge over its counterparts and establish itself as a trusted brand in the market.In addition to its focus on quality, the company recognizes the importance of sustainability and environmental consciousness. In line with China's commitment to reducing its carbon footprint, the company strives to minimize waste generation and optimize resource utilization during the manufacturing process. By adopting eco-friendly practices, the company aims to contribute to China's broader sustainability goals and foster a greener manufacturing ecosystem.With China's commitment to innovation, quality, and sustainability, the increased production of silicon carbide and silicone ice cube buckets is expected to meet the growing demand in both domestic and international markets. As Chinese manufacturers continue to invest in research and development and leverage their technological prowess, consumers can look forward to superior and reliable silicon carbide and silicone ice cube buckets that cater to their diverse needs.

The Advantages of Small Plastic Injection Moulds

Plastic Injection Mould Small is in high demand in many industries due to its ability to produce intricate and precise plastic components. The small size of these molds makes them ideal for producing small plastic parts, which are used in various consumer products, medical devices, automotive components, and electronic devices. This growing demand for small plastic injection molds has led to the development of advanced manufacturing techniques to meet the industry's requirements.The small plastic injection mold market is dominated by several key players who have a long history of providing high-quality products to their customers. These companies have a deep understanding of the intricacies involved in creating small plastic injection molds and have a proven track record of delivering top-notch products. One such company is {}, which has been a leader in the plastic injection molding industry for many years.{} is renowned for its expertise in designing and manufacturing small plastic injection molds. The company has a team of highly skilled engineers and designers who work tirelessly to create innovative and efficient mold designs. With state-of-the-art manufacturing facilities and cutting-edge technology, {} is able to produce small plastic injection molds that meet the exact specifications of its clients. The company has earned a reputation for delivering high-quality molds that are durable, reliable, and cost-effective.The small plastic injection molds produced by {} are used in a wide range of industries, including automotive, electronics, medical, and consumer goods. These molds are capable of producing complex geometries, tight tolerances, and intricate details, making them ideal for manufacturing small plastic parts. {} takes pride in its ability to provide customized mold solutions to meet the specific needs of its diverse clientele. The company works closely with its customers to understand their requirements and deliver molds that exceed their expectations.One of the key factors that set {} apart from its competitors is its commitment to continuous improvement and innovation. The company invests heavily in research and development to stay ahead of the curve and incorporate the latest advancements in mold design and manufacturing. This dedication to innovation has enabled {} to develop cutting-edge small plastic injection molds that deliver exceptional performance and reliability.In addition to its technical expertise, {} is also known for its outstanding customer service. The company has a team of dedicated professionals who are committed to providing exceptional support to its clients throughout the mold design and manufacturing process. {} understands the importance of fostering strong relationships with its customers and works tirelessly to ensure that their needs are met with the highest level of professionalism and care.As the demand for small plastic injection molds continues to grow, {} remains at the forefront of the industry, providing innovative solutions to its clients. The company's relentless pursuit of excellence and dedication to customer satisfaction have solidified its position as a trusted partner for small plastic injection mold needs.In conclusion, plastic injection molding is an essential manufacturing process that plays a critical role in various industries. The demand for small plastic injection molds continues to rise, driving the need for advanced manufacturing techniques and innovative solutions. With its unparalleled expertise, commitment to innovation, and exceptional customer service, {} is well-positioned to meet the evolving needs of the small plastic injection mold market and remain a leader in the industry.

Plastic Injection Mold For Power Socket: Everything You Need To Know

Plastic Injection Mold For Ac Power SocketIn today's fast-paced and technologically advanced world, the demand for efficient and reliable power sockets is more crucial than ever. As the market continues to expand, companies are constantly seeking innovative solutions to meet the growing needs of consumers. This is where a leading company in the industry, with its cutting-edge plastic injection mold for AC power sockets, comes into play.With a strong commitment to quality and innovation, [Company Name] is a renowned leader in the design and manufacture of plastic injection molds for a wide range of applications. The company has a proven track record of delivering high-quality products and services to its customers, and its expertise in the field of plastic molding is second to none.The plastic injection mold for AC power sockets is a testament to the company's dedication to providing superior products that meet the highest standards of functionality and durability. This particular mold is designed to meet the specific requirements of AC power sockets, ensuring a precise and reliable fit for a wide range of applications.One of the key features of this mold is its versatility, allowing for the production of a variety of different socket designs to accommodate the diverse needs of consumers. Whether it's a standard socket for residential use or a heavy-duty socket for industrial applications, this mold is capable of delivering consistent and high-quality results every time.The precision and accuracy of the mold are further enhanced by the company's state-of-the-art manufacturing processes, which are supported by advanced technology and a team of highly skilled engineers and technicians. This ensures that the final product meets the exact specifications and requirements of the customer, while maintaining the highest levels of quality and reliability.In addition to its technical capabilities, [Company Name] is also committed to sustainability and environmental responsibility. The company utilizes cutting-edge materials and processes that minimize waste and reduce the environmental impact of its operations. This aligns with the company's overall mission to provide innovative solutions that not only meet the needs of the market but also contribute to a more sustainable future.With its plastic injection mold for AC power sockets, [Company Name] is poised to make a significant impact in the market by delivering a product that is not only reliable and efficient but also environmentally friendly. By combining advanced technology with a commitment to quality and sustainability, the company continues to set the standard for excellence in the industry.As the demand for high-quality power sockets continues to grow, [Company Name] is well-positioned to meet the needs of its customers with its cutting-edge plastic injection mold. With a proven track record of success and a strong commitment to innovation, the company is set to make a lasting impact on the market and establish itself as a leader in the industry.In conclusion, the plastic injection mold for AC power sockets from [Company Name] represents a significant advancement in the field of plastic molding. With its focus on quality, innovation, and sustainability, the company is leading the way in delivering superior products that meet the ever-evolving needs of the market. As the demand for reliable power sockets continues to rise, [Company Name] stands ready to meet the challenge and deliver exceptional solutions that set the standard for excellence in the industry.

Plastic Injection Mould Molding Services for Custom Projects

Custom Plastic Injection Mould Molding is a company dedicated to providing high-quality plastic injection molding services for a wide range of industries. With their state-of-the-art facilities and experienced team of engineers and technicians, they are able to offer custom solutions for a variety of plastic molding needs.The company specializes in the design and manufacture of custom plastic molds, using advanced CAD/CAM software and CNC machining to create precise and complex mold designs. They work closely with their clients to understand their specific requirements and ensure that the final product meets their exact specifications.In addition to custom mold design and manufacturing, Custom Plastic Injection Mould Molding also offers a full range of plastic injection molding services. Their modern injection molding machines are capable of producing parts in a wide range of sizes and complexities, using a variety of thermoplastic and thermoset materials.One of the key advantages of working with Custom Plastic Injection Mould Molding is their ability to offer rapid prototyping services. This allows their clients to quickly and cost-effectively test new product designs before full-scale production, reducing time to market and minimizing risks.The company has a strong commitment to quality, and they adhere to strict quality control procedures throughout the entire manufacturing process. This ensures that every part they produce meets the highest standards of durability and performance.Custom Plastic Injection Mould Molding serves a diverse range of industries, including automotive, aerospace, medical, consumer electronics, and more. They have the flexibility to handle both low and high volume production runs, making them an ideal partner for companies of all sizes.In addition to their technical capabilities, Custom Plastic Injection Mould Molding is also dedicated to sustainability and environmental responsibility. They strive to minimize waste and energy consumption in their manufacturing processes, and they are able to offer eco-friendly material options for clients who are looking to reduce their environmental impact.With a strong focus on innovation and customer satisfaction, the team at Custom Plastic Injection Mould Molding is constantly looking for new ways to improve their processes and expand their capabilities. They invest in ongoing training and development for their employees, ensuring that they are always able to offer the latest and most advanced plastic molding solutions.In summary, Custom Plastic Injection Mould Molding is a leading provider of custom plastic injection molding services, offering high-quality, cost-effective solutions for a wide range of industries. With their advanced technology, commitment to quality, and strong focus on customer satisfaction, they are well-positioned to continue as a trusted partner for companies looking for custom plastic molding solutions.

Custom Plastic Injection Molding Services for Creating Quality Plastic Parts

Plastic Parts Injection Molding has become an essential manufacturing process for companies across various industries. This innovative technology allows for the production of high-quality, intricate plastic parts with incredible precision and efficiency. With the use of advanced machinery and techniques, companies are able to meet the growing demand for custom plastic parts, components, and products.One company that has made a significant impact in the plastic parts injection molding industry is {}. This company has established itself as a leader in the field, offering a wide range of injection molding services to meet the needs of its diverse clientele. With state-of-the-art facilities and a team of experienced professionals, {} has consistently delivered top-quality plastic parts to its customers, earning a reputation for excellence and reliability.{} specializes in providing custom injection molding solutions for a variety of applications, including automotive, electronics, medical devices, consumer goods, and more. The company's commitment to innovation and customer satisfaction has allowed it to forge strong partnerships with leading brands and businesses, positioning itself as a preferred supplier for plastic parts and components.The injection molding process employed by {} allows for the production of complex plastic parts with remarkable accuracy and consistency. By utilizing advanced machinery and tooling, the company is able to manufacture parts with tight tolerances and intricate geometries, meeting the exact specifications of its clients. This precision and attention to detail have made {} a trusted name in the industry, attracting businesses seeking high-quality plastic components for their products.In addition to its advanced manufacturing capabilities, {} also places a strong emphasis on sustainability and environmental responsibility. The company has implemented eco-friendly practices and processes into its operations, striving to minimize waste and reduce its carbon footprint. By using recyclable materials and optimizing energy usage, {} is dedicated to promoting a greener approach to injection molding, aligning with the growing global focus on sustainability.Furthermore, {} is committed to continuous improvement and innovation, investing in research and development to stay ahead of industry trends and technological advancements. The company consistently explores new materials, processes, and techniques to enhance its capabilities and offer cutting-edge solutions to its customers. By staying at the forefront of innovation, {} is well-positioned to address the evolving needs of the market and deliver innovative plastic parts to its clients.In response to the increasing demand for custom plastic parts, {} has expanded its production capacity and capabilities, ensuring that it can accommodate large-scale orders and tight deadlines. The company's ability to efficiently produce high volumes of plastic parts without compromising quality has made it a preferred supplier for businesses requiring mass production of components and products.With a customer-centric approach and a dedication to excellence, {} has earned the trust and loyalty of its clients, who rely on the company for their injection molding needs. By offering personalized service, fast turnaround times, and uncompromising quality, {} has established itself as a go-to partner for companies seeking reliable plastic parts manufacturing.As the demand for custom plastic parts continues to grow, companies like {} will play a crucial role in meeting the industry's needs and driving innovation. With its advanced capabilities, commitment to sustainability, and customer-focused approach, {} is well-positioned to remain a leader in the plastic parts injection molding industry, serving as a trusted partner for businesses across various sectors.

Plastic Injection Mold Manufacturers: Unveiling Key Players in the Industry

Title: Advancing Precision and Efficiency: Plastic Injection Mold Manufacturers Deliver Exceptional ProductsIntroduction:In today's fast-paced world, plastic injection molding plays a pivotal role in manufacturing a wide range of products across various industries. As demand continues to surge, the importance of high-quality plastic injection molds cannot be overstated. In this context, {Plastic Injection Mold Manufacturer} emerges as a leading player, leading the industry in delivering cutting-edge solutions for businesses worldwide.Company Overview:{Plastic Injection Mold Manufacturer} is a renowned name in the plastic injection molding industry. With years of industry experience, the company has established its reputation for delivering exceptional products that meet and exceed customer expectations.Using state-of-the-art technology and employing a team of highly skilled professionals, {Plastic Injection Mold Manufacturer} has quickly become a trusted source for precision molds. The company's commitment to quality, reliability, and customer satisfaction has propelled its growth and cemented its position as a market leader.Industry-Leading Solutions: With a primary focus on precision and efficiency, {Plastic Injection Mold Manufacturer} offers a comprehensive range of services to meet various customer requirements. The company's product portfolio includes:1. High-Quality Injection Molds:{Plastic Injection Mold Manufacturer} has a wide assortment of injection molds that cater to diverse industries, such as automotive, electronics, medical, and consumer goods. These molds are designed with utmost precision, ensuring flawless and consistent performance during the manufacturing process.2. Customization Capabilities:Recognizing that every client has unique needs, {Plastic Injection Mold Manufacturer} offers comprehensive customization options for its injection molds. Their team of expert engineers collaborates closely with clients, incorporating specific design features and functionalities into the molds, resulting in tailored solutions that maximize productivity and efficiency.3. Rapid Prototyping:In today's competitive industry landscape, speed is crucial. {Plastic Injection Mold Manufacturer} understands this and offers rapid prototyping services, enabling clients to bring their ideas to life quickly. This allows businesses to test and refine their products before full-scale production, saving time and costs.4. Tooling and Maintenance:To ensure longevity and consistent performance, {Plastic Injection Mold Manufacturer} provides comprehensive tooling and maintenance services. Their skilled technicians perform regular check-ups, repairs, and maintenance to extend the lifespan of injection molds, minimizing downtime and optimizing operational efficiency.Commitment to Quality:{Plastic Injection Mold Manufacturer} takes pride in its commitment to producing high-quality products. They adhere to stringent quality control measures throughout the manufacturing process, ensuring that each mold meets stringent industry standards. By employing advanced machines and employing skilled professionals while adhering to ISO-certified practices, the company maintains its excellence in delivering top-notch injection molds.Environmental Responsibility:In today's environmentally conscious world, manufacturers need to minimize their impact on the environment. {Plastic Injection Mold Manufacturer} recognizes this need and has incorporated sustainable practices into its operations. They utilize eco-friendly materials and processes that reduce waste generation and promote energy efficiency. By doing so, {Plastic Injection Mold Manufacturer} aligns its growth with environmental sustainability.Conclusion:With its unwavering commitment to precision, efficiency, and environmental responsibility, {Plastic Injection Mold Manufacturer} continues to stand out as a trusted and reliable partner for businesses seeking high-quality plastic injection molds. Through their extensive range of services and customization options, the company ensures that clients receive tailor-made solutions that optimize productivity and improve manufacturing processes. As the industry continues to evolve, {Plastic Injection Mold Manufacturer} remains dedicated to delivering exceptional products that exceed customer expectations and drive success in the competitive market.