High-Quality Injection Mold Maker for Plastic Manufacturing

By:Admin

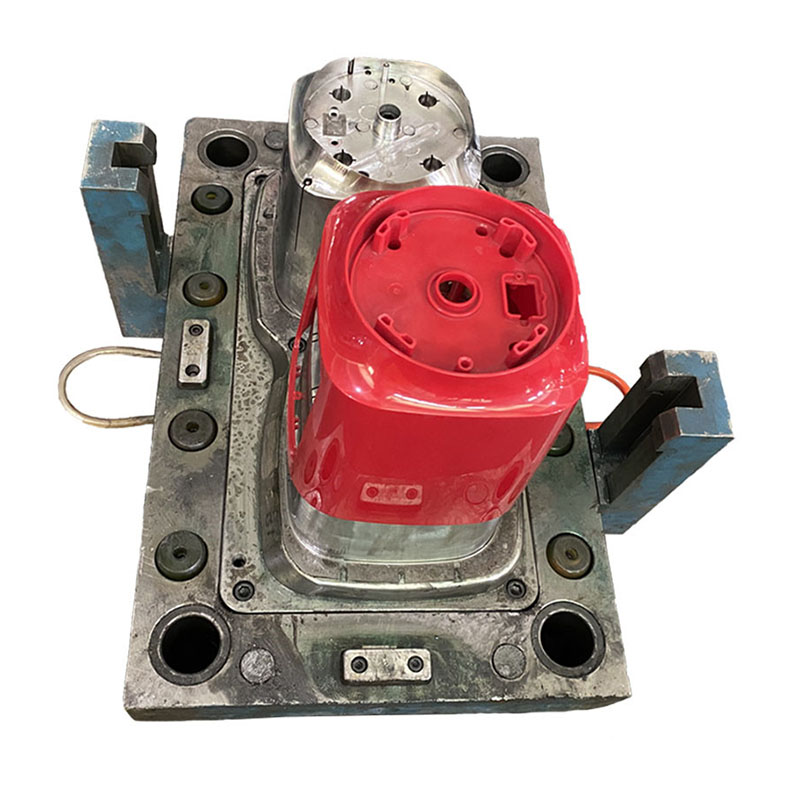

Founded in [year], Injection Mold Maker Plastic has established itself as a trusted partner for companies looking to produce high-precision plastic parts. The company's commitment to quality, precision, and customer satisfaction has made it a preferred choice for many businesses across different sectors.

With a focus on continuous improvement and innovation, Injection Mold Maker Plastic has invested in the latest technology and machinery to enhance its manufacturing capabilities. The company's fully automated manufacturing processes ensure consistently high-quality products with minimal lead times. This has allowed Injection Mold Maker Plastic to meet the ever-evolving demands of its customers while maintaining competitive pricing.

Injection Mold Maker Plastic offers a wide range of services, including product design, mold design and manufacturing, plastic injection molding, and assembly. This end-to-end solution allows the company to cater to the diverse needs of its customers and deliver comprehensive solutions that streamline the production process.

The company's team of experienced engineers and technicians work closely with clients to understand their requirements and develop customized solutions that meet their specific needs. Whether it's a complex, multi-cavity mold or a simple prototype, Injection Mold Maker Plastic has the expertise and capabilities to deliver exceptional results.

In addition to its manufacturing capabilities, Injection Mold Maker Plastic also places a strong emphasis on sustainability and environmental responsibility. The company has implemented eco-friendly practices in its manufacturing processes, ensuring minimal waste and energy consumption. This commitment to sustainability has not only earned Injection Mold Maker Plastic recognition as a responsible corporate citizen but has also positioned it as a preferred supplier for environmentally conscious companies.

Furthermore, Injection Mold Maker Plastic is dedicated to maintaining the highest standards of quality and safety. The company adheres to rigorous quality control measures throughout the manufacturing process to ensure that every product meets or exceeds industry standards. Additionally, Injection Mold Maker Plastic is committed to maintaining a safe and healthy work environment for its employees, fostering a culture of responsibility and excellence.

As part of its ongoing commitment to excellence, Injection Mold Maker Plastic regularly invests in research and development to stay ahead of industry trends and technological advancements. This drive for innovation has enabled the company to offer cutting-edge solutions that help its customers stay competitive in their respective markets.

Looking ahead, Injection Mold Maker Plastic is poised for continued growth and success in the plastic injection molding industry. The company's unwavering dedication to quality, customer satisfaction, and innovation will undoubtedly propel it to new heights and solidify its position as a leader in the industry.

In conclusion, Injection Mold Maker Plastic is a trusted partner for companies looking for high-quality plastic injection molds and comprehensive manufacturing solutions. With its advanced capabilities, commitment to excellence, and dedication to sustainability, Injection Mold Maker Plastic is well-equipped to meet the evolving needs of its customers and drive success in the plastic injection molding industry.

Company News & Blog

Unlocking the Power of Servo Motors in Injection Moulding Plastics

Title: Revolutionary Servo Motor Technology in Injection Moulding PlasticsIntroduction:In the ever-evolving world of manufacturing, companies are continuously seeking technological advancements to enhance production efficiency and improve product quality. One such breakthrough in the field of injection moulding plastics is the advent of Servo Motor Technology. This revolutionary innovation eliminates the limitations of conventional hydraulic systems and paves the way for more precise and energy-efficient manufacturing processes. This article delves into the transformative impact of Servo Motor Technology on injection moulding plastics and its potential to revolutionize the industry.I. Background:Injection moulding plastics, a widely adopted manufacturing process, involves the creation of plastic products through the injection of molten material into a mould. Traditionally, hydraulic systems powered by pumps were used to drive the injection process, resulting in limitations such as excess energy consumption, imprecise control, and inconsistent product quality. These shortcomings paved the way for the emergence of an alternative: Servo Motor Technology.II. Servo Motor Technology Explained:Servo motors, unlike hydraulic systems, utilize electrical power to drive the injection process. This cutting-edge technology offers superior control, precision, and efficiency. The servo motor system consists of a motor, an encoder, a controller, and a hydraulic accumulator. The encoder provides real-time data on the position and velocity of the motor, enabling the controller to regulate the injection process accurately. This ensures precise and repeatable positioning of the mould, resulting in uniform product quality.III. Advantages of Servo Motor Technology:1. Energy Efficiency: Servo motors consume considerably less energy compared to traditional hydraulic systems. By closely matching the speed and torque requirements of the injection process, the servo motor system reduces wasteful energy consumption, leading to substantial cost savings for manufacturers.2. Improved Precision and Control: Servo Motor Technology enables precise control over the injection process, offering greater accuracy in terms of shot weight, injection timing, and mould positioning. This not only enhances the overall quality of products but also reduces material waste and rework, making it an environmentally friendly solution.3. Reduced Noise Levels: Servo motors operate more quietly and smoothly as compared to hydraulic systems. This reduction in noise pollution contributes to a safer and more pleasant working environment for operators.IV. Application and Impact:The implementation of Servo Motor Technology drives advancements across various industries that rely on injection moulding plastics. Automotive, consumer goods, electronics, and packaging sectors are among the key beneficiaries of this transformative technology. Automakers benefit from accurate and consistent production of automotive parts, while the consumer goods industry enjoys improved product reliability and efficiency. Electronics manufacturers can achieve precise positioning of complex moulds, leading to enhanced product performance. Furthermore, the packaging industry benefits from increased productivity and minimized material waste.V. Market Outlook:The global injection moulding plastics market is projected to witness substantial growth owing to various factors, including the introduction of innovative technologies like Servo Motor Technology. Manufacturers are showing increased interest in adopting this technology to gain a competitive edge. Furthermore, the rising environmental concerns and stringent regulations related to energy consumption and carbon emissions are expected to propel the demand for energy-efficient solutions such as Servo Motor Technology.Conclusion:As the manufacturing industry seeks to optimize productivity and enhance product quality while minimizing energy consumption, Servo Motor Technology provides an effective solution for injection moulding plastics. The advantages of this groundbreaking technology, including improved precision, energy efficiency, and reduced noise levels, are poised to revolutionize the industry. With its widespread application across various sectors, Servo Motor Technology is set to usher in a new era of efficiency and sustainability in the injection moulding plastics market.

Plastic Injection Mold Manufacturers: Unveiling Key Players in the Industry

Title: Advancing Precision and Efficiency: Plastic Injection Mold Manufacturers Deliver Exceptional ProductsIntroduction:In today's fast-paced world, plastic injection molding plays a pivotal role in manufacturing a wide range of products across various industries. As demand continues to surge, the importance of high-quality plastic injection molds cannot be overstated. In this context, {Plastic Injection Mold Manufacturer} emerges as a leading player, leading the industry in delivering cutting-edge solutions for businesses worldwide.Company Overview:{Plastic Injection Mold Manufacturer} is a renowned name in the plastic injection molding industry. With years of industry experience, the company has established its reputation for delivering exceptional products that meet and exceed customer expectations.Using state-of-the-art technology and employing a team of highly skilled professionals, {Plastic Injection Mold Manufacturer} has quickly become a trusted source for precision molds. The company's commitment to quality, reliability, and customer satisfaction has propelled its growth and cemented its position as a market leader.Industry-Leading Solutions: With a primary focus on precision and efficiency, {Plastic Injection Mold Manufacturer} offers a comprehensive range of services to meet various customer requirements. The company's product portfolio includes:1. High-Quality Injection Molds:{Plastic Injection Mold Manufacturer} has a wide assortment of injection molds that cater to diverse industries, such as automotive, electronics, medical, and consumer goods. These molds are designed with utmost precision, ensuring flawless and consistent performance during the manufacturing process.2. Customization Capabilities:Recognizing that every client has unique needs, {Plastic Injection Mold Manufacturer} offers comprehensive customization options for its injection molds. Their team of expert engineers collaborates closely with clients, incorporating specific design features and functionalities into the molds, resulting in tailored solutions that maximize productivity and efficiency.3. Rapid Prototyping:In today's competitive industry landscape, speed is crucial. {Plastic Injection Mold Manufacturer} understands this and offers rapid prototyping services, enabling clients to bring their ideas to life quickly. This allows businesses to test and refine their products before full-scale production, saving time and costs.4. Tooling and Maintenance:To ensure longevity and consistent performance, {Plastic Injection Mold Manufacturer} provides comprehensive tooling and maintenance services. Their skilled technicians perform regular check-ups, repairs, and maintenance to extend the lifespan of injection molds, minimizing downtime and optimizing operational efficiency.Commitment to Quality:{Plastic Injection Mold Manufacturer} takes pride in its commitment to producing high-quality products. They adhere to stringent quality control measures throughout the manufacturing process, ensuring that each mold meets stringent industry standards. By employing advanced machines and employing skilled professionals while adhering to ISO-certified practices, the company maintains its excellence in delivering top-notch injection molds.Environmental Responsibility:In today's environmentally conscious world, manufacturers need to minimize their impact on the environment. {Plastic Injection Mold Manufacturer} recognizes this need and has incorporated sustainable practices into its operations. They utilize eco-friendly materials and processes that reduce waste generation and promote energy efficiency. By doing so, {Plastic Injection Mold Manufacturer} aligns its growth with environmental sustainability.Conclusion:With its unwavering commitment to precision, efficiency, and environmental responsibility, {Plastic Injection Mold Manufacturer} continues to stand out as a trusted and reliable partner for businesses seeking high-quality plastic injection molds. Through their extensive range of services and customization options, the company ensures that clients receive tailor-made solutions that optimize productivity and improve manufacturing processes. As the industry continues to evolve, {Plastic Injection Mold Manufacturer} remains dedicated to delivering exceptional products that exceed customer expectations and drive success in the competitive market.

Plastic Toy Molded Swing Car: A Fun and Safe Ride for Children

Title: Plastic Toy Used Mould Swing Car: An Affordable and Fun Way to Keep Children ActiveIntroduction:In today's fast-paced and technology-driven world, it is essential to encourage children to stay active and engage in physical activity. One such way to nurture their physical development while providing endless hours of fun is through the use of Plastic Toy Used Mould Swing Cars. As an affordable and exciting mode of transportation, these toys promote outdoor play and exercise, allowing children to stay active while enjoying themselves.Company Overview:ABC Manufacturing is a leading provider of high-quality plastic toys, known for its commitment to producing safe and innovative products. With a foundation built on child development and engagement, the company aims to create toys that stimulate imagination, encourage physical activity, and enhance motor skills.Plastic Toy Used Mould Swing Car: Captivating Young Hearts:The Plastic Toy Used Mould Swing Car has quickly gained popularity among children and parents alike. Its design incorporates a steering wheel, comfortable seat, and four wheels, making it safe and easy to operate. Children can propel themselves forward by gently swinging the steering wheel from side to side, providing a unique and exciting way to move around.One of the key advantages of the Plastic Toy Used Mould Swing Car is its affordability. With the rising costs of other children's toys and gadgets, this Swing Car provides an accessible option for parents seeking an engaging and beneficial playtime activity. The durable and lightweight design ensures a longer lifespan, making it an excellent investment for families looking for a long-term play solution.Promoting Physical Activity and Development:Physical activity is crucial for a child's development. The Swing Car encourages children to engage their core muscles while steering and propelling forward, providing an opportunity to strengthen coordination, balance, and overall motor skills. Additionally, the Swing Car’s simple operation allows children to experience a sense of independence and accomplishment as they navigate their surroundings.With the increasing prevalence of sedentary lifestyles, it is vital to provide children with avenues for physical exercise. The Swing Car motivates children to spend more time outdoors, away from screens, cultivating a healthier lifestyle from an early age. The joy and excitement experienced while driving the Swing Car foster a positive association with exercise, encouraging children to pursue active pursuits in the future.Endless Fun and Creativity:The Plastic Toy Used Mould Swing Car offers a range of opportunities for imaginative play. Children can pretend to be race car drivers, explorers, or simply go on adventure-filled journeys around the neighborhood. This versatility stimulates creativity and enhances cognitive abilities, allowing children to practice problem-solving and critical thinking skills.Moreover, the Swing Car can be enjoyed by children of various ages, making it an excellent investment for families with multiple siblings. The adjustable seat and easy maneuverability ensure that children of different heights and skill levels can enjoy the Swing Car to its fullest.Commitment to Safety:ABC Manufacturing prioritizes the safety of children above all else. The Plastic Toy Used Mould Swing Car is crafted from durable, non-toxic materials, ensuring a safe and secure playtime experience. The company adheres to strict quality control standards throughout the manufacturing process, guaranteeing that parents can trust the product for their children's playtime.Conclusion:The Plastic Toy Used Mould Swing Car from ABC Manufacturing offers an affordable and enjoyable way to keep children active and engaged. With its user-friendly design, promotion of physical activity, and emphasis on safety, this toy provides countless hours of fun for children while nurturing their motor skills and creativity. By incorporating the Swing Car into playtime routines, parents can encourage a healthier and more well-rounded childhood for their little ones.

Plastic Cup Injection Molding: Everything You Need to Know

Injection Molding Plastic Cup, a New Milestone Achievement for {Company}In today's fast-paced world, the development of new products is essential for companies to stay competitive in the market. One such innovative product that has recently been introduced by {Company} is the Injection Molding Plastic Cup. This new milestone achievement has set a benchmark in the industry, showcasing {Company}'s commitment to innovation and quality.{Company} is a leading manufacturer in the plastic industry, specializing in producing high-quality plastic products for various applications. With state-of-the-art facilities and a team of experienced professionals, {Company} has been at the forefront of technology and innovation. The company's commitment to sustainability and environmental responsibility has also been a driving force behind its success.The Injection Molding Plastic Cup is the latest addition to {Company}'s extensive product line. This innovative product has been designed to meet the growing demand for eco-friendly and durable plastic cups in the market. The cup is manufactured using advanced injection molding techniques, ensuring consistent quality and precision.One of the key features of the Injection Molding Plastic Cup is its durability. The cup is designed to withstand the rigors of daily use, making it ideal for both commercial and residential purposes. The high-quality plastic material used in the manufacturing process ensures that the cup is resistant to cracks, breakage, and deformation, making it a reliable choice for consumers.In addition to durability, the Injection Molding Plastic Cup also offers superior aesthetics. The cup is available in a range of attractive colors and finishes, catering to different consumer preferences. This attention to design and appearance reflects {Company}'s commitment to delivering products that not only perform well but also look great.Furthermore, the Injection Molding Plastic Cup is also a sustainable choice. {Company}'s focus on eco-friendly manufacturing practices has led to the development of a product that is recyclable and environmentally responsible. By choosing the Injection Molding Plastic Cup, consumers can contribute to the reduction of plastic waste and support sustainable initiatives.{Company} has invested significant resources into the research and development of the Injection Molding Plastic Cup, ensuring that it meets the highest standards of quality and performance. The company's dedication to continuous improvement and innovation is evident in the superior design and functionality of the product.Moreover, {Company} has also taken steps to ensure that the Injection Molding Plastic Cup complies with industry regulations and standards. Through rigorous testing and quality control measures, the company has demonstrated its commitment to delivering a product that meets the expectations of consumers and industry stakeholders.The introduction of the Injection Molding Plastic Cup is a significant milestone for {Company}, reaffirming its position as a leader in the plastic manufacturing industry. The company's ability to innovate and adapt to changing market demands sets it apart from its competitors, positioning it as a trusted partner for businesses and consumers alike.With the Injection Molding Plastic Cup, {Company} has once again demonstrated its ability to deliver products that combine quality, sustainability, and innovation. As the company continues to expand its product offerings, it is poised to make a lasting impact on the industry and set new standards for excellence.

Ultimate Guide to Injection Molding Manuals: Everything You Need to Know

Injection Molding Manuals, in combination with the company introduction, is revolutionizing the way injection molding processes are carried out in the industry today. This ground-breaking technology, developed by {}, is gaining widespread attention for its innovative approach to injection molding.The technology behind Injection Molding Manuals () is a game-changer in the industry. It is designed to provide comprehensive guidance and instructions for the injection molding process, bringing a new level of precision and efficiency to manufacturing operations. The manuals are meticulously curated to cover every aspect of injection molding, from machine set-up to material selection and quality control.What sets Injection Molding Manuals apart is its focus on providing real-time, on-demand support to operators and technicians on the shop floor. The manuals are accessible through a user-friendly interface, allowing workers to easily access the information they need to ensure a smooth and error-free molding process. This not only streamlines operations but also minimizes the risk of errors and reduces downtime.In addition, Injection Molding Manuals offers a comprehensive troubleshooting guide, enabling workers to quickly identify and resolve issues that may arise during the injection molding process. This is a significant advancement in the industry, as it can help manufacturers avoid costly delays and production setbacks.Furthermore, the company introduction of {} showcases their commitment to innovation and excellence in the field of injection molding technology. With a team of experienced professionals and a state-of-the-art manufacturing facility, they are dedicated to providing cutting-edge solutions that meet the ever-evolving needs of the industry.The company's dedication to continuous improvement and customer satisfaction is evident in the development of Injection Molding Manuals. By leveraging their expertise and industry knowledge, they have created a product that is set to revolutionize the way injection molding is carried out in manufacturing facilities around the world.One of the key benefits of Injection Molding Manuals is its ability to improve the overall efficiency of the injection molding process. By empowering workers with the knowledge and resources they need to optimize their operations, manufacturers can expect to see significant improvements in productivity and output.Moreover, the technology also has a positive impact on product quality and consistency. With clear and concise instructions at their fingertips, operators can ensure that each molded product meets the highest standards of quality, leading to greater customer satisfaction and brand reputation.As the industry continues to evolve, the demand for more advanced and efficient injection molding solutions is on the rise. Injection Molding Manuals, in combination with the expertise and dedication of {}, is well-positioned to meet this demand and lead the way in shaping the future of injection molding technology.In conclusion, Injection Molding Manuals, developed by {}, is a groundbreaking technology that is set to transform the way injection molding processes are carried out in the industry. With its comprehensive guidance and troubleshooting capabilities, this innovative solution is poised to improve manufacturing operations and drive greater efficiency and quality in the production of molded products. As {} continues to spearhead advancements in the field of injection molding technology, the industry can expect to see more innovative solutions that set new standards for excellence and performance.

Exploring the Growing Demand for Plastic Medical Injection Moulds

Title: Revolutionary Plastic Medical Injection Mould Pioneers Breakthrough Technologies in HealthcareIntroduction:(Date) - As the demand for efficient and safe medical equipment continues to rise, a renowned plastic injection mould company has unveiled its groundbreaking Plastic Medical Injection Mould. Developed in partnership with industry leaders and guided by advanced technologies, this innovative solution promises to revolutionize the production of medical equipment while ensuring optimal patient care and safety.Company Background:Founded in (year), (Company Name) has consistently been at the forefront of providing cutting-edge plastic injection mould solutions across various industries. Fueled by a commitment to innovation and customer satisfaction, the company has established a reputation for delivering superior products that meet the evolving needs of clients worldwide. With an uncompromising focus on quality and efficiency, (Company Name) has now set its sights on transforming the medical field.The Plastic Medical Injection Mould:The newly unveiled Plastic Medical Injection Mould showcases the culmination of years of research and development by (Company Name)'s team of experts. This revolutionary mould is designed to facilitate the production of high-quality and precise medical equipment, including syringes, IV catheters, infusion sets, and other vital medical components.Key Features and Benefits:1. Enhanced Precision and Accuracy: The Plastic Medical Injection Mould ensures the production of medical equipment with unparalleled precision and accuracy. With strict adherence to meticulous design specifications, it minimizes errors and discrepancies, guaranteeing the safety and effectiveness of the final product.2. Exceptional Material Compatibility: (Company Name)'s mould integrates advanced material compatibility features, allowing for seamless production with a wide range of medical-grade plastics. The mould is engineered to maintain the integrity of the materials used, ensuring the highest standards of quality and durability.3. Streamlined Production Process: Leveraging state-of-the-art automation technology, the Plastic Medical Injection Mould optimizes the production process, reducing cycle times and increasing output. This enables manufacturers to meet the growing demands of the healthcare industry while minimizing labor costs and maximizing efficiency.4. Strict Adherence to Regulatory Standards: Understanding the critical importance of regulatory compliance in the medical field, (Company Name) has rigorously tested the Plastic Medical Injection Mould to ensure adherence to global quality and safety standards. Manufacturers can be confident that their products will meet all necessary certifications and regulatory requirements.Impact on Healthcare:The launch of the Plastic Medical Injection Mould signifies a significant breakthrough in the healthcare industry. By enabling the production of premium medical equipment, healthcare providers can enhance the quality of patient care, reduce the risk of contamination, and streamline critical processes. The mould's reliable performance and compatibility with a range of plastics allow for cost-effective and sustainable manufacturing practices, making high-quality medical equipment more accessible to healthcare organizations worldwide.Future Prospects:Moving forward, (Company Name) is committed to continually pushing the boundaries of plastic injection mould technology to meet the evolving needs of the healthcare sector. By collaborating with medical professionals and industry stakeholders, the company aims to develop customized moulds that cater to specific medical equipment requirements, further improving patient outcomes and ensuring the highest levels of safety.Conclusion:With the introduction of the Plastic Medical Injection Mould, (Company Name) has established itself as a pioneer in developing innovative solutions for the healthcare industry. This groundbreaking mould's advanced features and benefits have the potential to revolutionize the way medical equipment is produced, enhancing patient care, and driving forward the progress of the healthcare sector as a whole.

Top Suppliers of Plastic Injection Molded Parts

[Suppliers Of Plastic Injection Molded Parts],With the increasing demand for plastic injection molded parts in various industries, the need for reliable suppliers has become more important than ever. One company that has stood out in this field is [company]. With a commitment to quality and customer satisfaction, they have become a trusted name in the industry.[Company] is a leading supplier of plastic injection molded parts, offering a wide range of products to meet the needs of their diverse clientele. From automotive components to consumer products, their expertise covers a broad spectrum of applications. The company prides itself on its state-of-the-art manufacturing facilities and a team of highly skilled professionals who are dedicated to delivering top-notch products.With an extensive portfolio of successful projects and satisfied clients, [company] has proven its ability to consistently meet and exceed the expectations of its customers. The company's commitment to quality and innovation has earned them a strong reputation in the industry, making them the go-to supplier for many businesses.One of the key factors that sets [company] apart from its competitors is its focus on continuous improvement and technological advancement. The company invests heavily in research and development to stay ahead of the curve and provide its customers with cutting-edge solutions. This proactive approach has enabled [company] to develop innovative products and processes that have redefined the standards in the industry.In addition to its strong technical capabilities, [company] prides itself on its unwavering commitment to customer satisfaction. The company understands the importance of building strong relationships with its clients and goes the extra mile to ensure that their needs are met. From providing personalized solutions to offering exceptional customer support, [company] is dedicated to making the entire experience seamless and hassle-free for its customers.Furthermore, [company] places a strong emphasis on sustainability and environmental responsibility in its operations. The company is dedicated to reducing its carbon footprint and minimizing waste through efficient manufacturing processes and responsible sourcing of materials. By championing eco-friendly practices, they not only contribute to a greener environment but also help their clients enhance their own sustainability efforts.As a testament to its excellence, [company] has been recognized with several prestigious awards and certifications in the industry. These accolades serve as a testament to the company's commitment to quality, innovation, and customer satisfaction.With a solid track record of success and a steadfast dedication to its core values, [company] continues to be a leading force in the supply of plastic injection molded parts. As the demand for these products continues to grow, the company is well-positioned to further expand its presence and solidify its reputation as a trusted and reliable partner for businesses across various industries.In conclusion, the value of a reliable and innovative supplier of plastic injection molded parts cannot be overstated, and [company] has proven itself to be a standout in this regard. With its unwavering commitment to quality, customer satisfaction, and sustainability, the company has set a high standard for the industry and continues to be a top choice for businesses seeking superior plastic injection molded parts.

Innovative Injection Molded Design Unveiled in Latest News

The company, a leading provider of injection molding solutions, has recently announced the launch of a new design injection molded product. The new design promises to revolutionize the industry with its innovative features and superior quality. This development marks a significant milestone for the company, as it continues to push the boundaries of injection molding technology and deliver cutting-edge solutions to its customers.The new design injection molded product is the result of extensive research and development efforts by the company's team of experts. Leveraging the latest advancements in injection molding technology, the product has been engineered to meet the highest industry standards and deliver exceptional performance. From its precise dimensions to its flawless finish, every aspect of the product has been meticulously designed to ensure superior functionality and durability.One of the key highlights of the new design injection molded product is its versatility. The product is capable of meeting a wide range of customer requirements, making it an ideal choice for various applications across different industries. Whether it's automotive, electronics, medical, or consumer goods, the product offers unmatched flexibility and adaptability, making it a valuable asset for businesses seeking reliable injection molding solutions.In addition to its versatility, the new design injection molded product also boasts of an ergonomic and user-friendly design. The company has gone to great lengths to ensure that the product is easy to use and integrate into existing manufacturing processes. This not only streamlines production processes but also enhances overall efficiency, resulting in cost savings and higher productivity for businesses.Furthermore, the new design injection molded product offers improved strength and durability, making it a long-lasting and reliable solution for manufacturers. The company has utilized advanced materials and manufacturing techniques to enhance the product's structural integrity, allowing it to withstand the most demanding operating conditions. This durability ensures that the product provides a long service life, ultimately contributing to lower maintenance costs and greater ROI for customers.With the launch of the new design injection molded product, the company reinforces its commitment to delivering innovative and high-quality solutions to its customers. This latest addition to the company's portfolio further solidifies its position as a trusted partner for businesses seeking top-notch injection molding capabilities. Customers can now rely on the company's expertise and state-of-the-art technology to meet their specific needs and stay ahead of the competition.In conclusion, the new design injection molded product represents a major leap forward for the company and the injection molding industry as a whole. By pushing the boundaries of technology and innovation, the company continues to set new standards for quality, performance, and reliability. With its unmatched versatility, user-friendly design, and exceptional durability, the product is set to make a significant impact across various industries. As the company looks ahead, it remains dedicated to developing cutting-edge solutions that empower businesses and drive success in the dynamic world of injection molding.

Custom Injection Molding for High-Quality Injection Parts

Injection Parts Molding Company, a leader in the field of injection molding, is revolutionizing the industry with its innovative and high-quality products. The company is dedicated to providing solutions for a wide range of industries, including automotive, medical, consumer electronics, and more. With state-of-the-art technology and a team of experienced professionals, Injection Parts Molding Company is setting new standards for excellence in the field of injection molding.The company's commitment to quality is evident in its dedication to using the latest and most advanced technology in the industry. This technology allows Injection Parts Molding Company to produce high-quality parts with incredibly tight tolerances. This level of precision is essential for industries such as automotive and medical, where the smallest imperfection can have significant consequences. By utilizing the latest technology, Injection Parts Molding Company ensures that its products meet the highest standards of quality and reliability.In addition to its cutting-edge technology, Injection Parts Molding Company also prides itself on its team of experienced professionals. The company's engineers and technicians have a wealth of knowledge and expertise in the field of injection molding, allowing them to provide innovative and effective solutions for their clients. Whether it's creating custom molds for unique parts or providing guidance on material selection, Injection Parts Molding Company's team is committed to delivering exceptional results for its customers.The company's dedication to excellence has not gone unnoticed. Injection Parts Molding Company has received numerous accolades and awards for its outstanding performance and contributions to the field of injection molding. These accolades are a testament to the company's ongoing commitment to innovation and quality, and serve as a testament to the company's outstanding performance in the industry.But what truly sets Injection Parts Molding Company apart from its competitors is its commitment to customer satisfaction. The company understands that every project is unique, and it works closely with its clients to understand their specific needs and requirements. By taking the time to understand the unique challenges and opportunities of each project, Injection Parts Molding Company is able to deliver truly customized solutions that exceed its clients' expectations. This customer-centric approach has earned the company a reputation for excellence and reliability, making it the go-to choice for injection molding solutions.Furthermore, Injection Parts Molding Company is committed to sustainable and environmentally friendly practices. The company is dedicated to reducing its environmental impact and minimizing waste in its manufacturing processes. By implementing eco-friendly practices and using recyclable materials, Injection Parts Molding Company strives to be a responsible corporate citizen and contribute to a cleaner, more sustainable future.In conclusion, Injection Parts Molding Company is a leader in the field of injection molding, with a strong commitment to excellence, innovation, and customer satisfaction. With its cutting-edge technology, experienced team, and dedication to sustainable practices, Injection Parts Molding Company is setting new standards for quality and reliability in the industry. Whether it's producing parts for the automotive, medical, or consumer electronics industry, Injection Parts Molding Company is the top choice for high-quality injection molding solutions.

Top Plastic Injection Mould Manufacturer Offers Quality Products at Competitive Prices

Plastics Injection Mould Manufacturer, a leading provider of high-quality injection moulds for the plastics industry, has recently announced their continued commitment to excellence and customer satisfaction. With over 20 years of experience in the industry, the company has earned a reputation for delivering innovative solutions and superior products to their clients worldwide.As a prominent player in the plastics injection moulding sector, Plastics Injection Mould Manufacturer prides itself on its state-of-the-art facilities, cutting-edge technology, and a team of highly skilled professionals. Their dedication to precision engineering and attention to detail have enabled them to consistently meet the evolving demands of their customers across various industries, including automotive, medical, consumer goods, and more.Through their unwavering commitment to quality and continuous improvement, Plastics Injection Mould Manufacturer has built strong relationships with their clients, who rely on them for their moulding needs. The company's comprehensive range of services includes product design assistance, prototyping, tooling, and production, ensuring that they can offer end-to-end solutions for their customers' diverse requirements."We are proud to be at the forefront of the plastics injection moulding industry, delivering cutting-edge solutions that meet the highest standards of quality and performance," said the spokesperson of Plastics Injection Mould Manufacturer. "Our team is dedicated to pushing the boundaries of innovation and exceeding the expectations of our clients. We are committed to maintaining our position as a trusted partner in the industry, providing unparalleled expertise and support every step of the way."In addition to their commitment to excellence, Plastics Injection Mould Manufacturer is also focused on sustainability and environmental responsibility. The company has adopted eco-friendly manufacturing practices and invests in energy-efficient technologies to minimize their environmental impact. They are continuously exploring new ways to reduce waste and improve their environmental footprint, aligning with their dedication to corporate social responsibility.Furthermore, Plastics Injection Mould Manufacturer remains at the forefront of industry trends and advancements, constantly investing in research and development to enhance their capabilities and stay ahead of the competition. By staying abreast of the latest technologies and best practices, the company ensures that they can deliver cutting-edge solutions that empower their clients to remain competitive in their respective markets.As they move forward, Plastics Injection Mould Manufacturer is poised to continue their legacy of excellence, innovation, and customer-centric approach. With a firm commitment to quality, sustainability, and continuous improvement, the company is well-positioned to meet the evolving needs of the plastics industry and exceed the expectations of their valued clients.About Plastics Injection Mould ManufacturerPlastics Injection Mould Manufacturer is a leading provider of high-quality injection moulds for the plastics industry. With over 20 years of experience, the company is dedicated to delivering innovative solutions and superior products to clients worldwide. Their comprehensive range of services includes product design assistance, prototyping, tooling, and production, making them a trusted partner for end-to-end solutions. Plastics Injection Mould Manufacturer is committed to excellence, sustainability, and continuous improvement, setting industry standards and exceeding customer expectations.